-

-

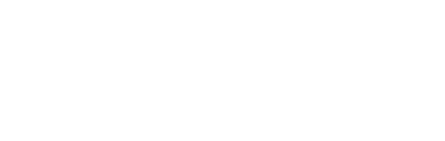

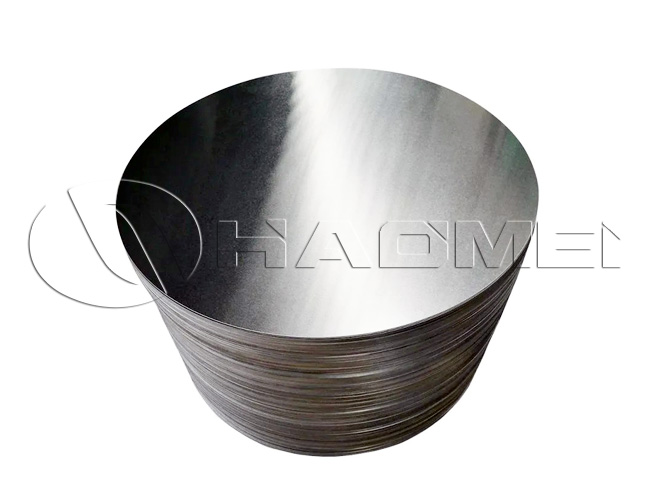

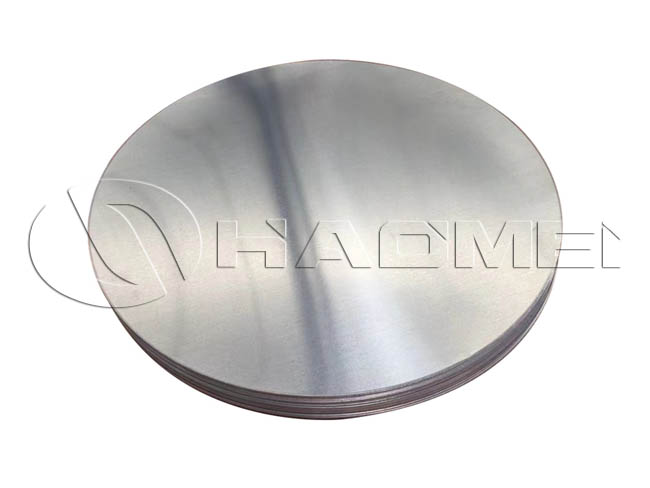

Aluminum Circles for Cookware

- Alloy 1050,1060,1070,3003,5052,8011,etc

- Tempers O, H12, H14, H16, H18, etc.

- Thickness 0.3 -6.0 mm

- Diameter 100 - 1600 mm

- Surface Treatment Anodized, coated, brushed, etc.

- Production Process CC / DC

- Packaging Wooden pallets, customizable

- MOQ 1-3 tons

HAOMEI Aluminum uses high-quality cast-rolled or hot-rolled aluminum coils as raw materials. After different cold rolling deformations, slitting, and annealing, the coils are finally stamped into aluminum circles. Our aluminum circles have finer grains, uniform size, excellent mechanical properties, and stable thermal conductivity, making them ideal for producing cookware.

Cookware aluminum circles are mainly made from 1xxx, 3xxx, 5xxx, and 8xxx series aluminum alloys. They are typically cut directly from aluminum coils or sheets into round shapes. With precise processing, they feature uniform thickness and smooth surfaces, widely used for manufacturing inner pots, pot bodies, lids, and other cookware accessories.

Material Selection for Cookware Aluminum Circles

1xxx series aluminum alloys: e.g., 1050, 1060, 1070, 1100, 1200. High purity, low strength, and low cost, suitable for cookware with lower strength requirements, such as kettles and extruded pot lids.

3xxx series aluminum alloys: A typical grade is 3003. With manganese added, it has higher strength and corrosion resistance than the 1xxx series. Commonly used in making non-stick pans, pressure cookers, and other premium cookware.

5xxx series aluminum alloys: e.g., 5052, 5754. With higher strength and excellent corrosion resistance, suitable for cookware parts that need to withstand pressure and wear.

8xxx series aluminum alloys: e.g., 8011. Medium strength, good corrosion resistance, and excellent processing performance, often used in inner cookware liners.

Product Information - Cookware Aluminum Circles

| Alloy Grades | 1050, 1060, 1100, 1200, 3003, 5052, 8011 |

| Tempers | O, H12, H14, H16, H18, etc. |

| Thickness | 0.3 mm - 6.0 mm |

| Diameter | 30 mm - 1600 mm |

| Surface Treatment | Anodized, coated, brushed, etc. |

| Production Process | CC / DC |

| HS Codes | 7606.9100; 7606.9200 |

| Standards | ASTM-B209, GB/T3880-2012, EN485 |

| Packaging | Wooden pallets, customizable |

| MOQ | 1-3 tons |

Chemical Composition of Different Alloys (%)

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Ni | Zn | Ti | Al |

| 1050 | 0.25 | 0.40 | 0.05 | 0.05 | 0.05 | - | - | 0.05 | 0.03 | 99.5 |

| 1060 | 0.25 | 0.35 | 0.05 | 0.03 | 0.03 | - | - | 0.05 | 0.03 | 99.6 |

| 1070 | 0.2 | 0.25 | 0.04 | 0.03 | 0.03 | - | - | 0.04 | 0.03 | 99.7 |

| 1100 | 0.95 | 0.05-0.20 | 0.05 | - | - | - | 0.10 | - | 99 | |

| 1200 | 1.0 | 0.05 | 0.05 | - | - | - | 0.10 | - | 99 | |

| 3003 | 0.60 | 0.70 | 0.05-0.20 | 1.0-1.5 | - | - | - | 0.10 | - | Remainder |

| 5052 | 0.25 | 0.40 | 0.40 | 0.10 | 2.2-2.8 | 0.15-0.35 | - | 0.10 | - | Remainder |

| 8011 | 0.50-0.90 | 0.6-1.0 | 0.10 | 0.20 | 0.05 | 0.05 | - | 0.10 | - | Remainder |

Why Choose Aluminum Circles for Cookware?

Safe and non-toxic: Aluminum is a commonly used safe metal in the food industry.

Lightweight: Reduces the overall weight of cookware, making it easier to handle.

Fast and uniform heat conduction: Ensures quick heating and cooling, with even heat distribution to food.

Corrosion and rust resistance: The oxide film on the surface prevents rusting.

Easy to process: Excellent formability, suitable for stamping and deep drawing.

Cost-effective: Affordable and offers great value.

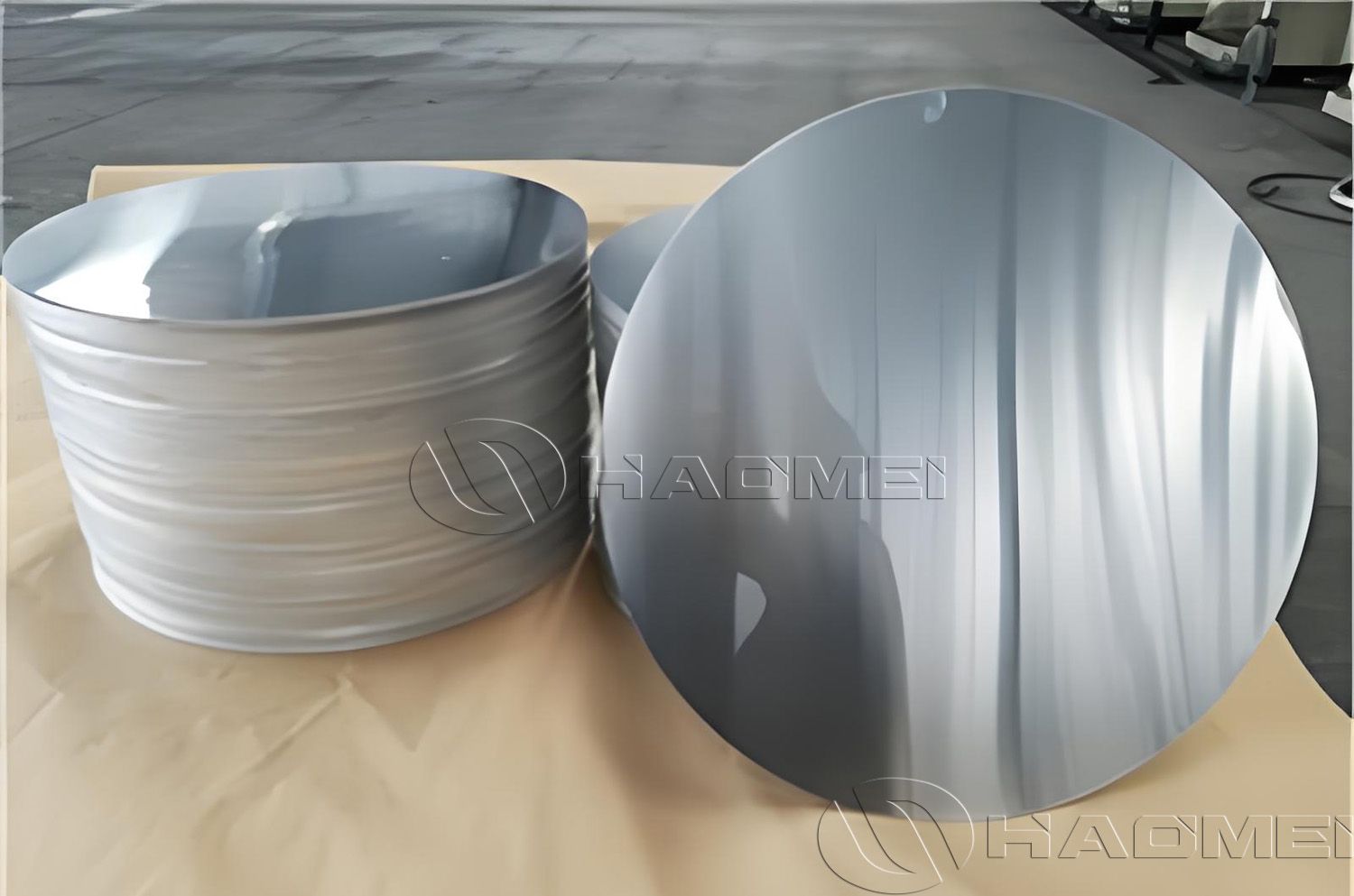

Applications of cookware aluminum wafer

Non-stick pans: Used as the base material, with non-stick coating applied after surface treatment.

Pressure cookers: Used for the cooker’s body or base, providing high strength and excellent heat transfer to ensure safe and efficient operation under pressure.

Other cookware: Widely used in making frying pans, woks, stockpots, baking trays, and more, supporting convenient daily cooking.

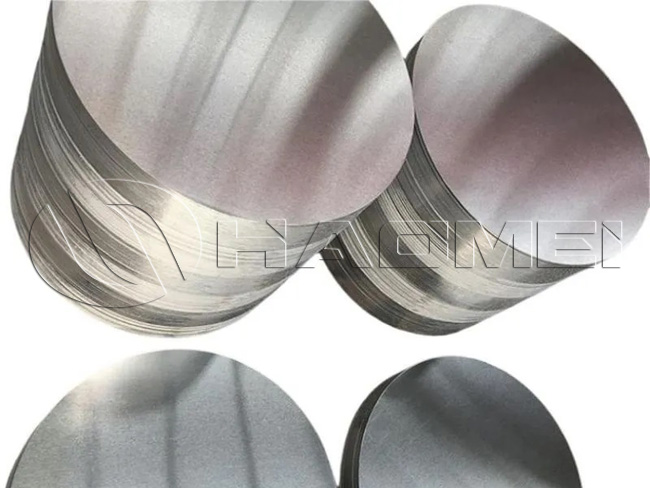

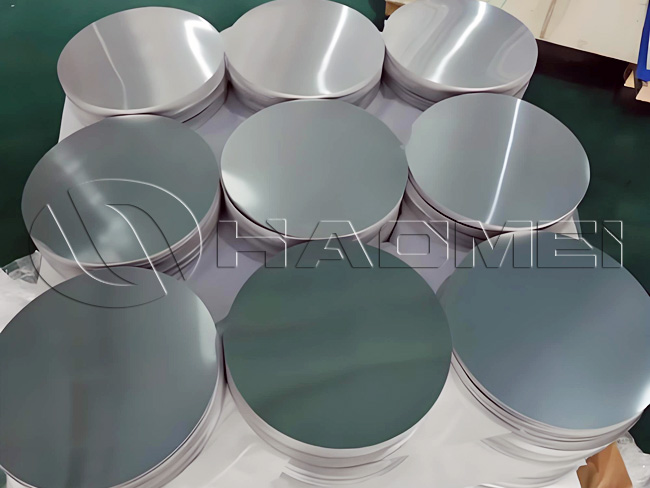

Specifications of Aluminum Circles

Thickness: Usually between 0.5 mm and 6.0 mm. Thicker circles are often chosen for the cookware bottom to ensure better heat conduction and durability.

Diameter: Wide range available and customizable. Small sizes (tens of mm) for utensils, large sizes (hundreds of mm) for big pots.

How are aluminum circle discs produced?

The processing steps for aluminum discs are generally divided into two aspects: 1. Cutting the blank (cutting into squares). 2. Blanking.

Depending on the level of automation of the production equipment, it can be categorized as either shearing machine processing or automatic disc punching line processing.

Fully automatic disc stamping line processing: The aluminum circle disc uncoiling and stamping line is a fully automatic, integrated aluminum disc production line. It punches discs directly from aluminum coils, eliminating the need for shearing or slitting. This product is widely used in aluminum processing to manufacture stretched aluminum discs for cookware.

Aluminum wafers with a diameter of less than 800 mm are generally produced using fully automatic disc placing machines. Aluminum discs with a diameter of more than 800 mm are widely used in highway signage and are generally produced using shearing machines.

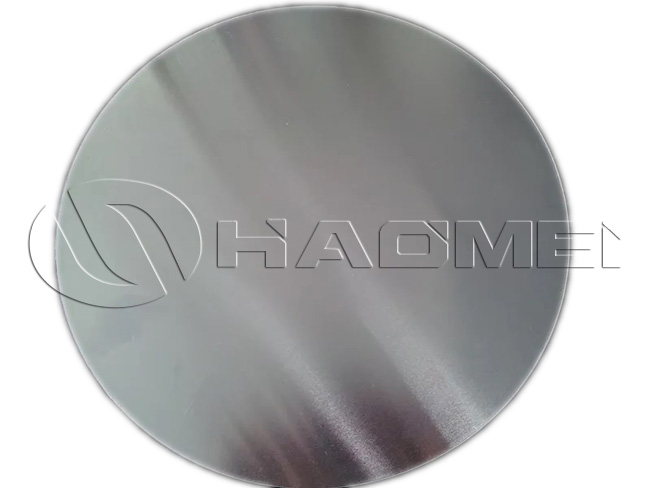

Processing Methods for Cookware Aluminum Circles

After production, aluminum circles undergo further processing into cookware. The main forming methods are:

Deep Drawing: Suitable for one-time or multi-step forming of cookware with deeper or more complex shapes, such as pots and liners.

Spinning: Forming by rotation and pressure, often used for round, symmetrical cookware components.

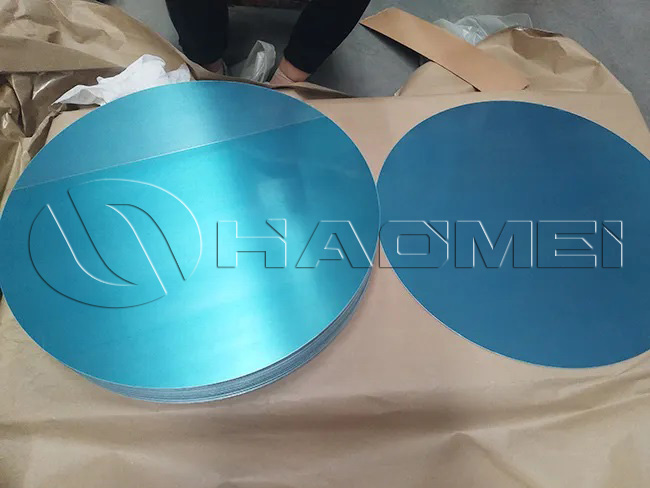

Surface Treatment Options:

Anodizing: Improves corrosion and wear resistance with decorative effects.

Powder coating: Attractive and protective, suitable for products with high appearance and durability requirements.

Sandblasting: Creates a smooth, uniform matte finish.

Electroplating: Enhances mechanical, chemical, and physical performance.

Polishing: Improves aesthetics, functionality, and durability.

Brushing: Creates uniform linear textures, enhancing scratch resistance and visual appeal.

Factors Affecting the Price of Aluminum Circles

Raw material cost: Aluminum ingot is the main raw material. Its price fluctuations directly determine circle costs. Influenced by the global aluminum futures market, supply-demand balance, energy costs (especially electricity), and smelting technologies.

Size and thickness: Larger or non-standard sizes, as well as very thin or very thick circles, increase production difficulty and scrap rate, leading to higher costs. Standard sizes are usually more cost-effective.

Alloy grade and purity: Different alloys vary in price. High-purity aluminum (1xxx series) and alloys (3xxx, 8xxx) differ due to alloying elements and their costs. Some special alloying elements increase production cost.

Manufacturer: Different producers with varying equipment and processes result in different product quality and prices.

No.14 Waihuan Road, CBD, Zhengzhou, China

No.14 Waihuan Road, CBD, Zhengzhou, China +86-18703635966

+86-18703635966

+86-18703635966

+86-18703635966

sales@alummc.com

sales@alummc.com

8618703635966

8618703635966