-

-

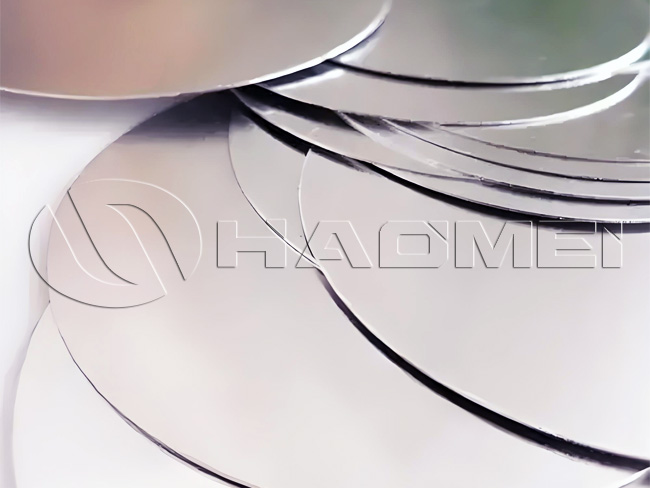

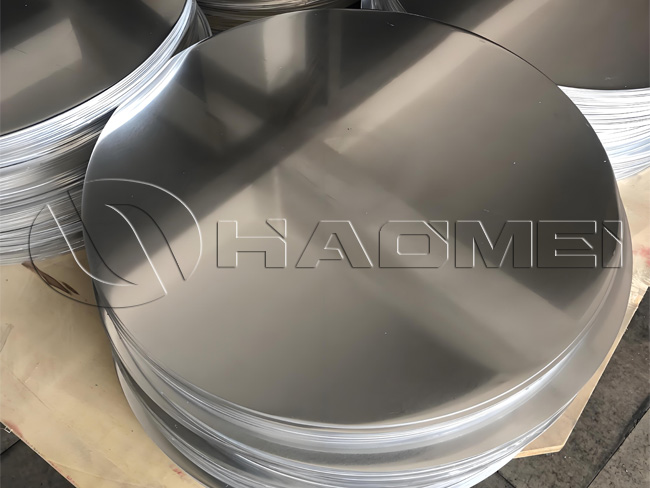

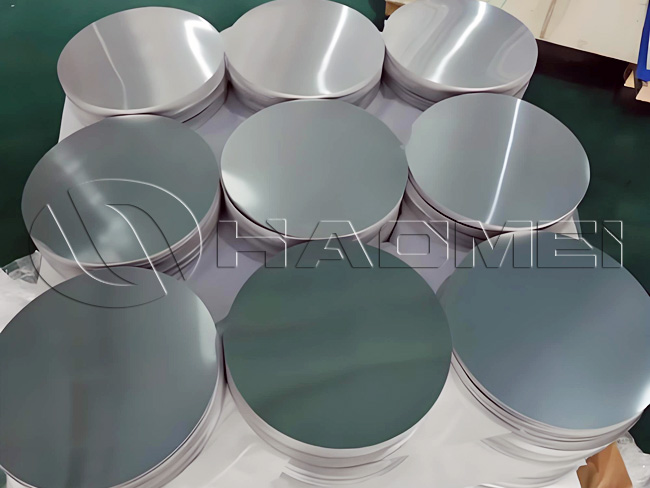

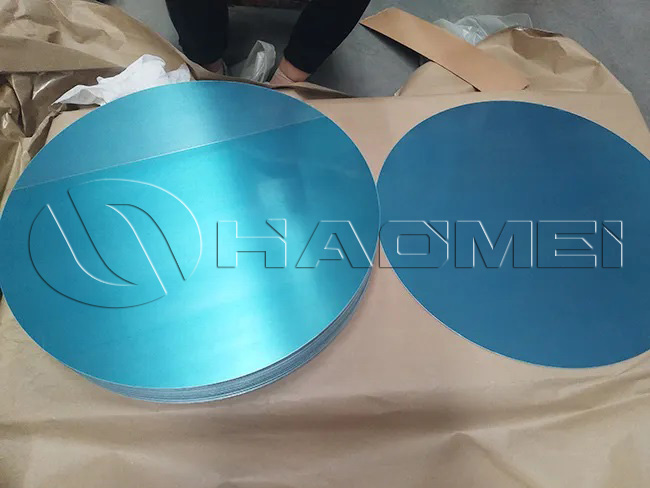

1050 Aluminum Circle

- Alloy 1050

- Thickness 0.30-10.00 mm

- Diameter 100-980 mm

- Process DC / CC

- Technology Rolling and cutting

- Applications Cookware, lighting, frying pans, etc

- MOQ 1-3 tons

Introduction

1050 aluminum belongs to the pure aluminum series, with an aluminum content of over 99.5%. It has good ductility, thermal conductivity, and corrosion resistance, but relatively low strength. Aluminum circles are commonly used in deep drawing products, reflector panels, decorative items, and more.

The common tempers of 1050 aluminum circles include F, O, H12, H14, H16, H18, H24, etc. Among them, H24 represents a half-hard temper achieved through specific processing, suitable for applications requiring certain strength but that cannot be strengthened by heat treatment.

Our 1050 aluminum circles are highly suitable for spinning and deep drawing. With aluminum purity as high as 99.5%, they avoid cracking or “orange peel” problems during processing. They are also ideal for design purposes and are exported to Saudi Arabia, Egypt, Kuwait, the USA, Korea, Russia, Canada, Italy, and many other countries and regions.

1050 aluminum circles are available in various types and thicknesses.

HAOMEI Aluminum produces 1050 aluminum circles in a wide range of grades and thicknesses to meet different application needs. Specifications are usually defined by thickness and diameter, ranging from 0.5 mm to 6 mm in thickness and from tens of millimeters to over 1,000 mm in diameter.

HAOMEI offers 1050 O, 1050 H12, 1050 H14 aluminum circles, widely used in the production of cookware and utensils. Both CC and DC qualities are available.

Specifications of 1050 Aluminum Circle

| Alloy | 1050 |

| Temper | O, H12, H14, H16, H18, H22, H24, H26, H32 |

| Thickness | 0.30–10.00 mm |

| Diameter | 100–980 mm |

| Process | Hot rolled (DC), Cold rolled (CC) |

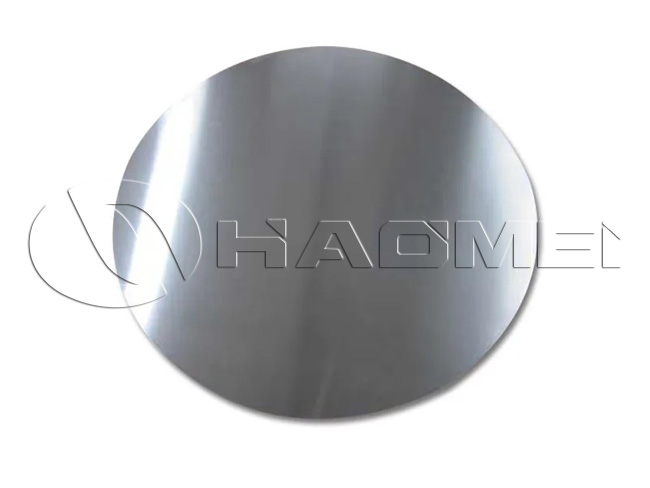

| Surface Quality | Bright surface, free from scratches |

Chemical Composition (%)

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Ni | Zn | Ti | Al |

| 1050 | 0.25 | 0.4 | 0.05 | 0.05 | 0.05 | - | - | 0.05 | 0.03 | 99.5 |

Mechanical Properties

| Temper | Thickness (mm) | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) |

| O | 0.3-6 | 60-100 | 30-50 | ≥20 |

| H12 | 0.5-6 | 70-120 | ≥95 | ≥4 |

| H14 | 85-120 | - | ≥2 | |

| H24 | 95-125 | 75 | ≥6 |

Advantages of 1050 Aluminum Circles

Excellent corrosion resistance against atmosphere and freshwater.

Superior elongation and tensile strength.

High plasticity and excellent workability, suitable for stamping and drawing.

Ideal for spinning applications.

Excellent for deep drawing (DDQ quality).

Good electrical and thermal conductivity.

High reflectivity.

Weldable by conventional methods.

Good tolerance for pressure processing, bending, and forming.

Simple composition and low production cost, making it cheaper than alloyed aluminum.

Production Features of 1050 Aluminum Circles

Continuous production: Using a combined melting furnace and holding furnace in the continuous casting and rolling line. Degassing and slag removal are thorough. Continuous production can reach 1,300 tons, with each coil weighing 6–8 tons.

Precision control: Thickness tolerance is monitored by Siemens thickness controller during rolling. For coils weighing 2.5-3 tons, tolerance between the leading and trailing edges can be kept within ±0.01 mm, while flat sheets can achieve ±0.002 mm.

Punching accuracy: When a 2.5-ton coil is fed into a punching machine, the uncoiling and leveling ensure continuous punching. The mold diameter tolerance is ±0.01 mm. Even after 50 million punches, molds maintain tolerance and sharpness, minimizing burr formation.

Annealing process: Entire coils are placed in annealing furnaces with hot air circulation fans, ensuring uniform heating of all pieces.

Differences between 1050 O, H12, H14, H18 Aluminum Circles

1050-O: Fully annealed, soft temper with no internal stress, maximum plasticity and ductility. Best for deep drawing, stretching, and spinning, used in milk cans, kettles, pots, etc.

1050-H12 / H22: Quarter-hard temper. Strength is higher than O temper while maintaining good ductility. Suitable for moderate forming, such as kitchen utensils, lids, and covers.

1050-H14 / H24: Half-hard temper, medium strength and ductility. Commonly used for non-deep drawing cookware and lampshades.

1050-H18: Full-hard temper with maximum strength but very low ductility. Typically used in road signs, electrical enclosures, and building panels.

Applications of 1050 Aluminum Circles

Cookware & household products: Pan bases, induction cooker coil substrates, deep-drawn cookware (pot lids, aluminum pots).

Lighting & decoration: Lamp reflectors (downlights, streetlights), decorative panels, signage, ceilings.

Industrial parts: Chemical container linings, heat sinks, stamped electrical parts, traffic signs.

Special requirements: Chemical equipment and applications where high oxidation resistance and formability are required but strength is not.

Production Process

Alloy ingot preparation

Melting furnace

Holding furnace

DC casting machine – slab

Rough rolling mill

Hot rolling mill

Cold rolling mill

Punching process

Annealing furnace

Final inspection

Packaging

Delivery

What are Spinning and Deep Drawing Aluminum Circles?

Spinning Aluminum Circles

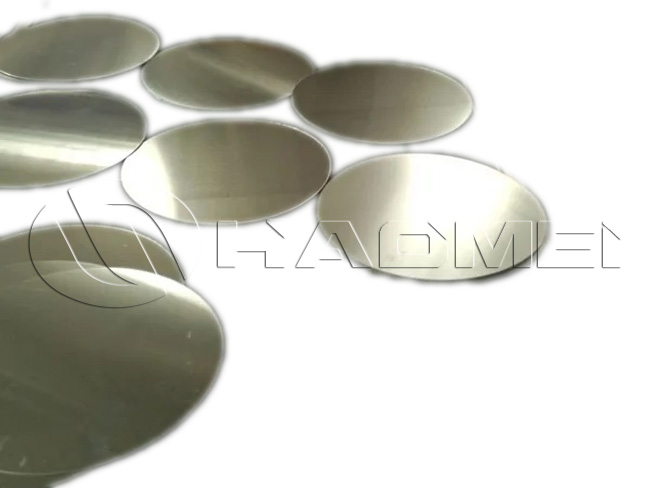

Spinning can be done manually or by CNC machine, using wood or metal tooling. Also known as spin forming, spinning, or metal turning. For aluminum circles, spinning involves pressing the circle against a rotating mold with rollers, gradually forming hollow rotational parts. Commonly used for cookware such as pots, pans, and baking trays. For spinning, CC aluminum circles are excellent since deep drawing is not required.

Deep Drawing Aluminum Circles (DD)

Deep drawing is a sheet metal forming process where the aluminum circle is pressed into a forming die at high speed. For depths exceeding 150 mm (DDQ quality), DC material is recommended. 1050 aluminum circles are ideal for both deep drawing and spinning.

Quality Control

Appearance: Visual inspection ensures no scratches, oil stains, or oxide spots. Minor scratches less than 0.02 mm deep and 2 mm long are acceptable.

Dimensional accuracy: Diameter and thickness checked with calipers and micrometers. Batch products must meet GB/T 3190 standards with ≥95% pass rate.

Performance testing: Samples undergo tensile testing, requiring yield strength ≥35 MPa, tensile strength 60-100 MPa, elongation ≥28%.

Comparison with Other Aluminum Circles

Features: Most widely used anti-rust aluminum alloy, contains Mn, about 10–20% stronger than 1050. Maintains excellent formability, weldability, and corrosion resistance.

Applications: Pressure vessels, storage tanks, building materials, cookware, and lighting.

Features: Medium-strength Al-Mg alloy with excellent fatigue resistance and strong corrosion resistance in marine environments. Much stronger than 1050 and 3003.

Applications: Transportation, ship parts, sheet metal, electronic product housings requiring high corrosion resistance.

6061 Aluminum Circle

Features: Heat-treatable Al-Mg-Si alloy, one of the most widely used structural alloys. Highest strength among these grades, but lower formability.

Applications: Aircraft structures, bicycle frames, bridges, and load-bearing mechanical parts.

Export Packaging

Aluminum circles are packed according to export standards, wrapped in kraft paper and plastic film, then fixed on wooden pallets or wooden cases.

Place desiccants near the aluminum circles to keep them dry and clean.

Wrap with clean plastic film for sealing.

Wrap with kraft paper over plastic for additional sealing.

Packaging options: wooden pallet with hard paper wrapping or wooden box packaging.

Secure with steel straps over wooden packaging to ensure firmness and safety.

No.14 Waihuan Road, CBD, Zhengzhou, China

No.14 Waihuan Road, CBD, Zhengzhou, China +86-18703635966

+86-18703635966

+86-18703635966

+86-18703635966

sales@alummc.com

sales@alummc.com

8618703635966

8618703635966