-

-

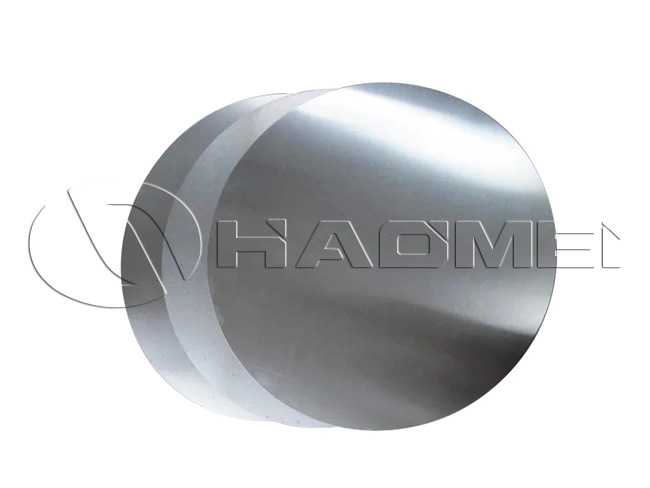

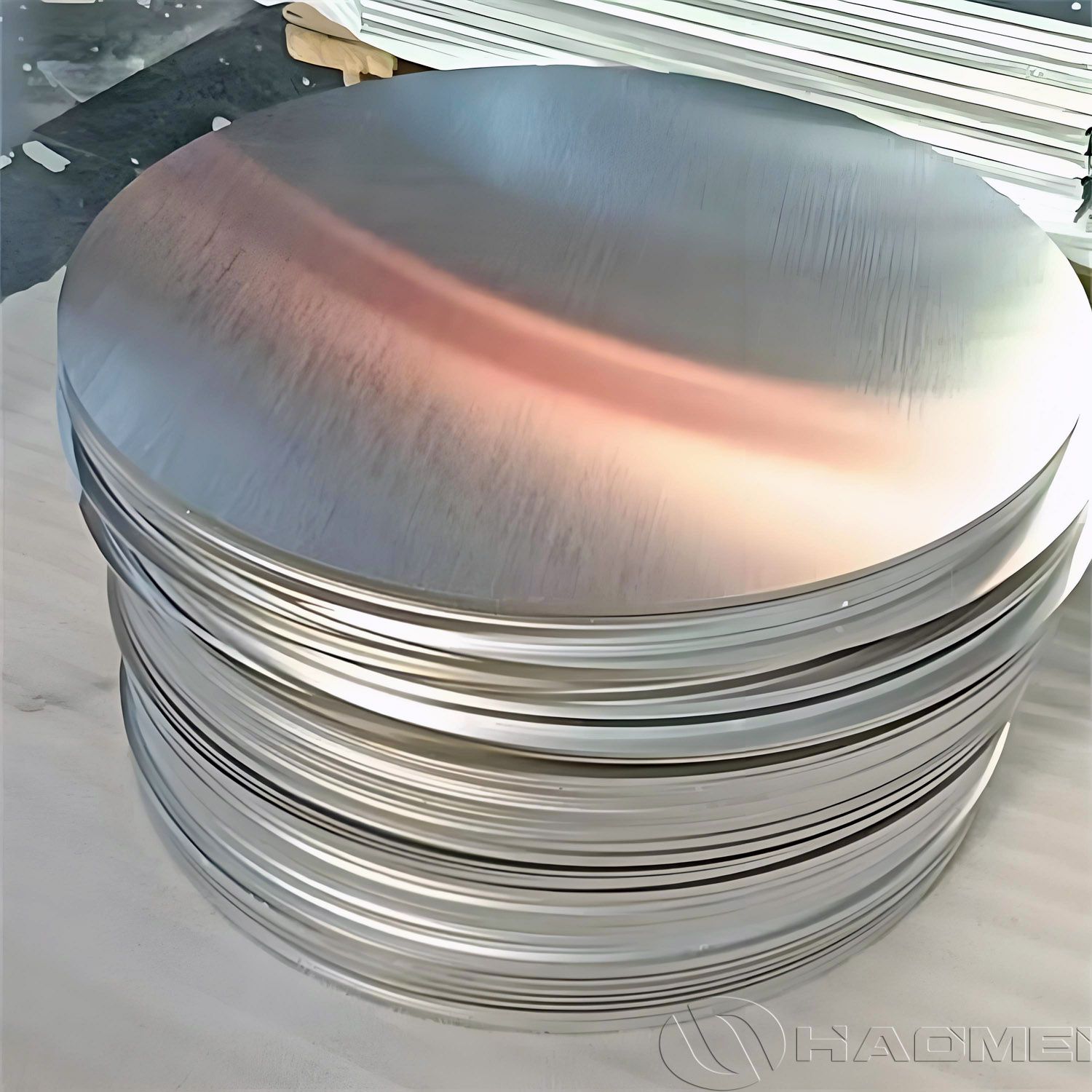

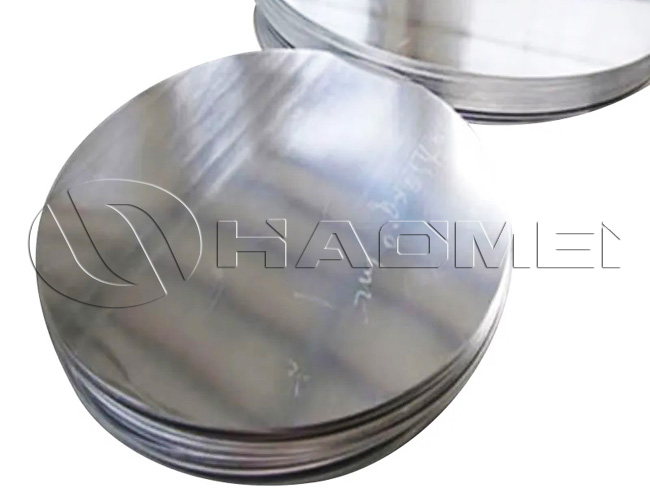

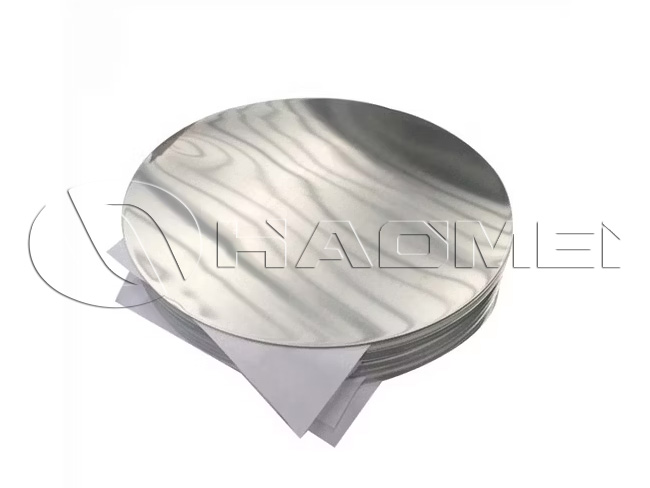

3005 Aluminum Circle

- Alloy 3005

- Tempers O, H14, H24, H18, H16, H22, H26

- Thickness 0.5 mm – 10 mm

- Diameter 50 mm – 1200 mm

- Surface Finish Options Polished, bright, mirror, brushed, hairline, sandblasted, checkered, embossed, etched, etc.

- MOQ 1-3 tons

What is 3005 Aluminum Circle?

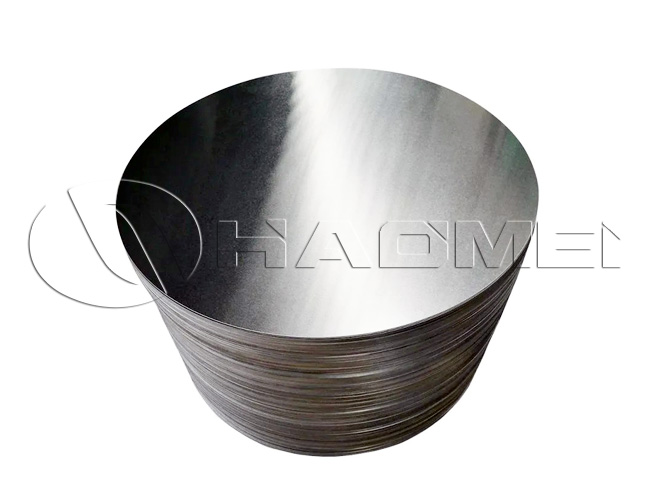

3005 aluminum circle is a round sheet material processed from 3005 aluminum alloy. It belongs to the aluminum-manganese alloy family (3xxx series) with the addition of magnesium, which makes it stronger than 3003 alloy. This makes 3005 circles highly suitable for applications requiring both higher strength and excellent formability.

Typical Tempers of 3005 Aluminum Circle

H12: Slightly work-hardened but not fully annealed. Offers higher strength with moderate ductility, suitable for applications requiring medium hardness.

H14: One of the most common tempers of 3005. Moderately work-hardened, harder than H12, with higher strength but slightly reduced ductility. Widely used in cookware bottoms and lighting products.

H18: Fully work-hardened, with maximum strength and hardness but minimum ductility. Difficult to bend or form, suitable for parts where strength is more important than formability.

O (Annealed): Fully annealed condition with maximum softness and ductility but the lowest strength. Most suitable for deep drawing and complex forming processes.

Specifications of 3005 Aluminum Discs

| Tempers | O, H14, H24, H18, H16, H22, H26 |

| Thickness | 0.5 mm - 10 mm |

| Diameter | 50 mm - 1200 mm |

| Standards | GBT, EN, ASTM, JIS |

| Certifications | ISO, SGS, BV |

| Surface Finish Options | Polished, bright, mirror, brushed, hairline, sandblasted, checkered, embossed, etched, etc. |

| MOQ | 1-3tons |

Chemical Composition (%)

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Ni | Zn | Ti | Others | Al |

| 3005 | 0.6 | 0.7 | 0.3 | 1.0-1.5 | 0.2-0.6 | 0.1 | - | 0.25 | 0.1 | 0.2 | Remainder |

Key Features of 3005 Aluminum Circle

Higher strength than 3003: With magnesium addition, strength is about 20% higher than 3003.

Excellent corrosion resistance: Outstanding weather resistance, especially in atmospheric environments.

Good formability: Suitable for deep drawing, stretching, and other forming processes.

Good weldability: Well-suited for TIG/MIG welding and similar techniques.

Applications of 3005 Aluminum Circles

Building and Decoration: Widely used for ceiling panels, curtain walls, louvers, downpipes, etc., combining strength and anti-rust capability.

Lighting and Hardware: Production of lampshades, reflectors, and various hardware housings.

Chemical Containers: For tanks, covers, and containers requiring corrosion resistance.

Automotive Parts: Non-critical components and some interior parts.

Others: Electrical panels, nameplates, bottle caps, etc.

Comparison with Other Aluminum Circles

3005 vs. 3003:

3005 is an improved version of 3003, with very similar composition but slightly higher strength, giving it an advantage in applications requiring greater mechanical performance.

3005 vs. 3105:

3105 contains small amounts of silicon and iron, making it slightly stronger than 3005. However, for more complex or deeper drawing applications, 3005 may perform better.

3005 vs. 1050/1060:

3005 offers superior strength and corrosion resistance compared to pure aluminum series, though its electrical and thermal conductivity is somewhat lower.

3005 vs. 5052:

5052 has significantly higher strength and superior corrosion resistance, particularly in marine environments. However, 5052 is more expensive and less suitable for deep drawing, where 3005 shows better formability.

No.14 Waihuan Road, CBD, Zhengzhou, China

No.14 Waihuan Road, CBD, Zhengzhou, China +86-18703635966

+86-18703635966

+86-18703635966

+86-18703635966

sales@alummc.com

sales@alummc.com

8618703635966

8618703635966