No.14 Waihuan Road, CBD, Zhengzhou, China

No.14 Waihuan Road, CBD, Zhengzhou, China

+86-18703635966

+86-18703635966

No.14 Waihuan Road, CBD, Zhengzhou, China

No.14 Waihuan Road, CBD, Zhengzhou, China

+86-18703635966

+86-18703635966

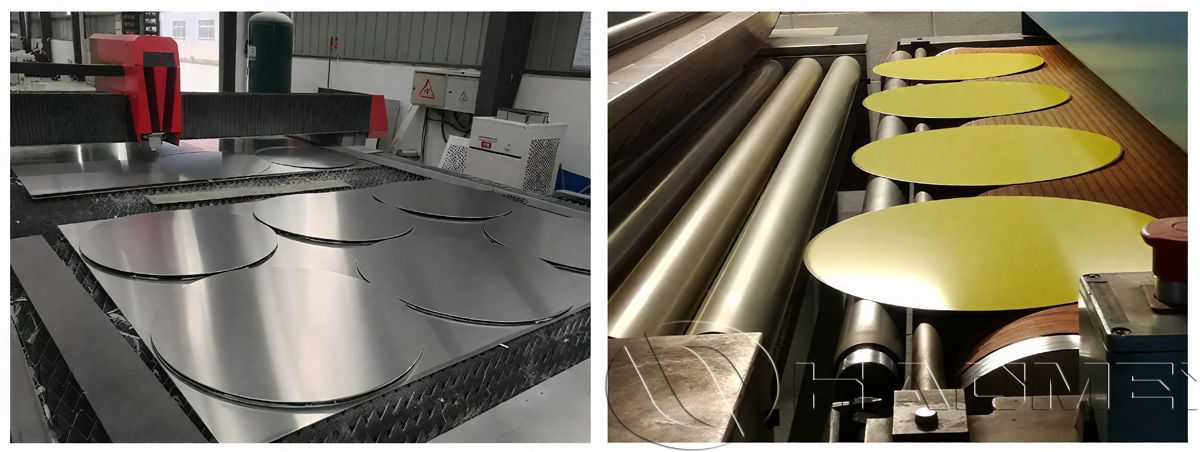

HAOMEI Aluminum provides anodized aluminum circle discs with excellent anodizing effect, stable performance, and high surface quality. They are widely used in the production of lampshades, cookware, traffic signs, and more. Available in series 1, 3, 4, 5, and 8 aluminum alloys, with customizable dimensions and surface finishes including anodizing, brushing, and coating, to meet a wide range of processing requirements.

Anodizing is an electrochemical process that generates a hard, porous oxide film on the aluminum surface. This oxide layer provides high hardness, corrosion resistance, and good insulation. Most anodized films are semi-transparent, presenting aluminum’s natural silver appearance. However, through various anodizing techniques, the surface can absorb lubricants or dyes, or be electrolytically colored, achieving golden, champagne, black, and other decorative effects.

Lampshade aluminum circles are commonly produced from 1050, 1060, 1100, 3003, 5052 alloys. They are wear-resistant, corrosion-resistant, and scratch-proof, making them ideal for lampshade manufacturing-especially in modern household lighting, commercial lighting, and industrial lighting equipment-offering a combination of lightweight, aesthetic appeal, and durability.

1xxx Series (1050, 1060):

Industrial pure aluminum with aluminum content over 99.5%. Features excellent ductility, easy stamping and forming, perfect for complex deep-drawn lampshades. With minimal alloying elements, the anodized surface is very pure, resulting in vivid and uniform colors. However, the strength is relatively low.

3xxx Series (3003):

An aluminum-manganese alloy with higher strength and better corrosion resistance than the 1xxx series. 3003 aluminum discs offer good anti-rust properties, suitable for humid environments. Often used in commercial lighting and outdoor lighting fixtures.

5xxx Series (5052):

A magnesium-aluminum alloy known for high strength, excellent corrosion resistance, and good formability. Ideal for large-diameter lampshades or applications in high-humidity environments. After anodizing, it provides a fine matte or brushed texture effect.

Lightweight and Durable: Aluminum's low density ensures even large lampshades remain light and easy to install. The oxide film enhances surface hardness, scratch resistance, and cleaning convenience.

Excellent Heat Dissipation: As a good thermal conductor, aluminum helps dissipate heat for LED lamps, extending lifespan and ensuring safety.

Eco-Friendly and Safe: The anodizing process produces no harmful substances. Products are non-toxic, odorless, and meet green building standards. The oxide film also provides insulation, improving electrical safety.

Light Control: By adjusting oxide film thickness and surface treatment, the reflection and diffusion of light can be precisely controlled.

Sustainability: Aluminum is recyclable, and the anodizing process is pollution-free, supporting sustainable development.

Cost-Effective: Compared with stainless steel or glass lampshades, aluminum discs are lighter and less expensive to process.

| Alloy | Temper | Thickness (mm) | Diameter (mm) | Main Usage |

| 1050 DC | O | 0.5-6.0 | 120-900 | Cookware, Lampshade |

| 3003 DC | O | 0.5-6.0 | 120-900 | Cookware, Lampshade |

| 3003 DC | H14-H22 | 1.0-8.0 | 120-900 | Cookware, Lampshade |

| 3004 DC | O | 1.0-6.0 | 120-900 | Cookware, Lampshade |

| 5052 DC | O/H14-H22 | 1.0-3.0 | 135-900 | Cookware, Road signs |

| 8A06 | O | 1.0-8.0 | 120-650 | Cookware, Lampshade |

| 8011 | O | 1.0-4.5 | ≤500 | Cookware, Rice cooker inner pot |

Two main forming techniques transform flat aluminum blanks into beautiful lampshades:

Deep Drawing:

The aluminum disc (blank) is placed on a forming die and pushed into the cavity with a punch. This process shapes the metal into cup- or shell-like forms, producing seamless lampshades with uniform wall thickness. Deep drawing quality (DC) aluminum discs are essential for crack-free forming.

Metal Spinning:

The aluminum disc rotates at high speed on a lathe. A forming tool presses the disc against a mandrel (die with the desired internal shape) to gradually form the lampshade. Spinning is ideal for producing conical, hemispherical, and other symmetrical shapes, offering design flexibility and cost efficiency for small-batch or prototype production.

Raw Material Preparation: Select high-purity aluminum, cut and clean it for anodizing.

Anodizing Treatment: Place aluminum in an anodizing tank under controlled temperature and voltage, forming a dense oxide film.

Post-Treatment: Clean and dry the anodized aluminum to improve weather and corrosion resistance.

Shaping: Process into discs or other required shapes and sizes.

Quality Inspection: Ensure each disc meets quality and performance standards.

Packaging & Shipping: Products are carefully packed to ensure safe delivery.

Color Variety: Anodized aluminum discs are available in multiple colors, including champagne, silver white, bronze, rose gold, and black, instead of only the natural silver-gray. This provides more options and enhances aesthetics.

Superior Corrosion Resistance: The anodized coating acts as a protective barrier, isolating the metal from the environment, significantly improving rust resistance and extending service life. The coating also enhances wear resistance.

Better Workability: Compared with ordinary aluminum discs, anodized aluminum discs offer excellent bending and processing properties, making them more versatile in applications.

Copyright © 2026 By HAOMEI Aluminum CO., LTD. All Rights Reserved. Sitemap