-

-

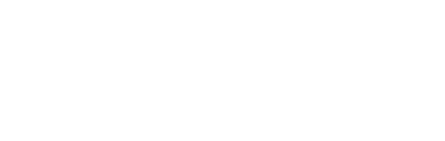

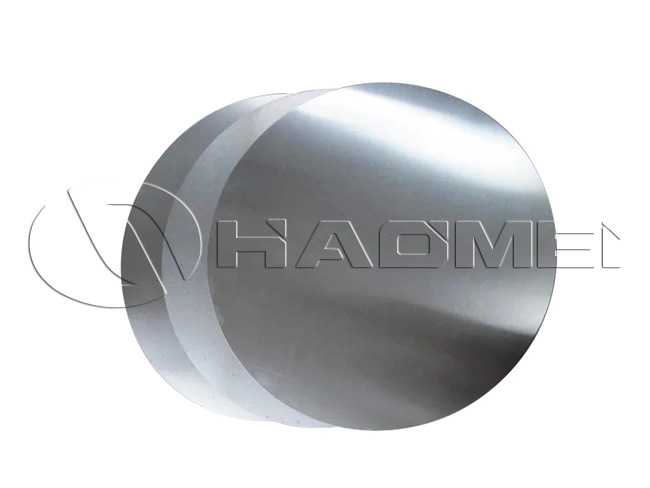

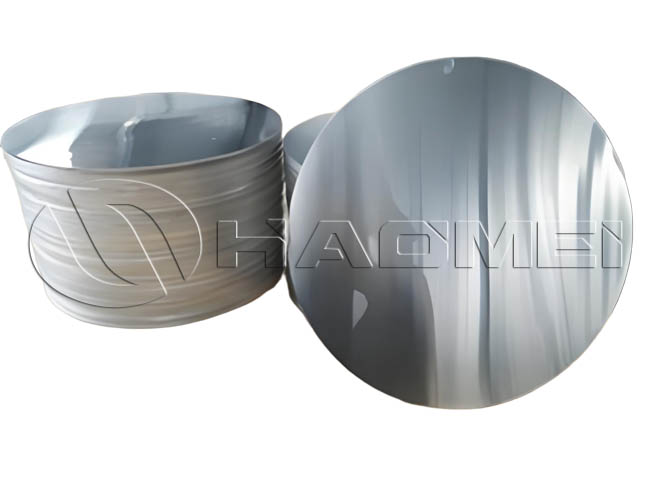

Aluminum Circles for Lampshades

- Alloy 1050, 1060, 1100, 3003, 3105, 5052, 5754, etc.

- Diameter 80mm - 1200mm

- Thickness 0.5mm - 6.0mm

- Production Process DC,CC

- Applications Lampshade components for downlights, streetlights, spotlights, industrial lighting

- Delivery Time About 25 days

- Samples 1-3 pieces available

- MOQ 1-3 tons

With over 20 years of production experience, HAOMEI Aluminum is a leading manufacturer of aluminum circles and a primary supplier of aluminum discs for lighting. We specialize in producing high-quality anodized aluminum circles and coated aluminum circles for lampshade manufacturing. These are widely used in spotlights, recessed lighting, high-bay and low-bay industrial lights, traffic signal reflectors, and sports lighting applications.

Aluminum circles for lampshades are circular aluminum materials specifically designed for the lighting industry. They are usually made from 1000, 3000, 5000, or 8000 series alloys, each offering unique performance characteristics to meet diverse lampshade design needs.

Common Alloy Categories

1000 Series Aluminum Circles (e.g., 1060, 1070, 1100):

With aluminum content over 99%, they offer excellent formability and high reflectivity. Their stable anodizing performance makes them ideal for lampshades requiring superior light reflection.3000 Series Aluminum Circles (e.g., 3003, 3004):

Known for excellent formability, high elongation, fine grain structure, and smooth surfaces. Their high reflectivity and deep drawing ability make them suitable for complex lampshade designs.5000 Series Aluminum Circles (e.g., 5052, 5754):

Contain magnesium, offering high strength and excellent corrosion resistance against seawater and humid environments. They are widely used in industrial lighting, explosion-proof lamps, and outdoor lighting housings.

Types of Aluminum Circles for Lighting

Anodized Aluminum Circles

Provide enhanced surface hardness, corrosion resistance, and semi-specular to high-reflective surfaces, commonly used in high-reflectivity lampshades.Coated Aluminum Circles

Painted or coated to achieve decorative effects, matte surfaces, or vibrant colors, improving aesthetics.Plain Aluminum Circles

Used in simple lighting where no special reflective effect is required.

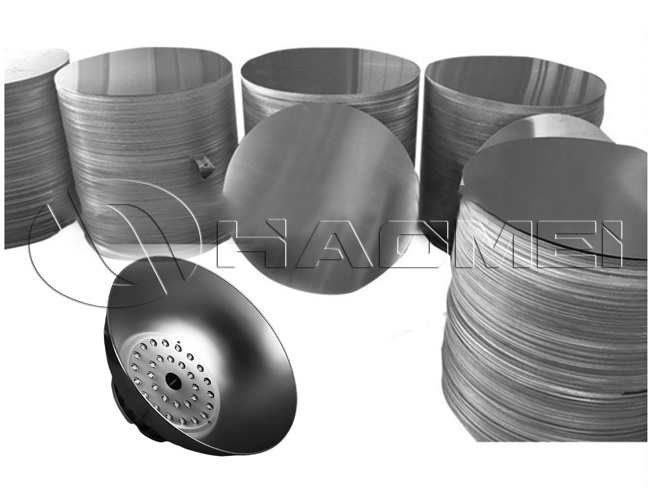

Aluminum Wafer Product Information

| Alloy Grades | 1050, 1060, 1100, 3003, 3105, 5052, 5754, etc. |

| Temper | O, H12, H14, H16, H18, H24 |

| Diameter Range | 80mm - 1200mm |

| Thickness Range | 0.4mm - 6.0mm |

| Production Process | CC (Cold Rolled), DC (Hot Rolled) |

| Surface Treatment | Polished, Brushed, Anodized, Color Coated, Mirror Finished |

| Tolerance | Thickness ≤ ±0.05mm; Diameter ≤ ±0.5mm |

| Surface Quality | Free from scratches, oil stains, black spots, or cracks |

| Applications | Lampshade components for downlights, streetlights, spotlights, industrial lighting |

| Packaging | Standard export wooden pallets / moisture-proof kraft paper / protective film |

| Delivery Time | About 25 days |

| Samples | 1-3 pieces available |

| MOQ | 1-3 tons |

Choosing Lampshade Aluminum Disc Sizes

Lampshade aluminum discs come in a wide range of thicknesses, from 0.5mm to 6.0mm. Generally speaking, thinner discs are suitable for small decorative lamps, while thicker discs are better suited for larger outdoor lighting fixtures.

A wide range of diameters is available to meet the production needs of lampshades of varying sizes.

Why use aluminum circle discs for lampshades?

When making a lampshade, the material you choose is crucial. Aluminum discs have excellent heat dissipation properties, quickly dissipating heat to the outside, improving heat dissipation efficiency and ensuring the brightness and lifespan of the lighting fixture.

After undergoing a meticulous anodizing or polishing process, aluminum discs can achieve a high light reflectivity of over 95%, maximizing light efficiency and making the lamp more energy-efficient and brighter.

Furthermore, aluminum discs have excellent plasticity and ductility, making them well-suited for spinning and deep drawing processes, meeting various forming requirements. They can also withstand long-term use in humid or corrosive environments, resisting rust and corrosion, thus ensuring the longevity of the lamp.

How is a lampshade made from aluminum circles?

1. Raw Material Preparation

The raw materials used to produce aluminum discs are generally 1-series, 3-series, or 5-series aluminum alloys, selected based on the product requirements.

The typical thickness of a lampshade ranges from 0.5mm to 1.5mm, and the diameter depends on the size of the lampshade. Customization is available upon request.

2. Stamping

Mold Design: The mold design is based on the shape and size of the lampshade. The precision and quality of the mold directly impact the quality of the final product.

Stamping Process: The aluminum disc is placed on a stamping press and passed through the die through multiple presses, gradually forming the desired shape. During the stamping process, controlling the pressure and speed is crucial to ensure uniform deformation without cracks or wrinkles.

3. Graphic Design

Initial Stretching: After stamping, the initially formed aluminum disc is placed on a stretching press. Passing through the stretching die, the disc undergoes initial stretching. This process requires gradually increasing the stretching force to prevent cracking.

Fine Drawing: After the initial stretching, the aluminum disc undergoes fine drawing to achieve the final shape and size of the lampshade. This requires repeated drawing and adjustment to ensure a smooth and even surface.

4. Trimming and Finishing

Trimming: The edges of the drawn lampshade may have excess material or uneven areas. Use a trimmer to remove excess material and ensure a neat edge.

Finishing: The lampshade undergoes finishing processes such as grinding and polishing to ensure a smooth and flawless surface. During the finishing process, additional steps such as drilling or other modifications may be performed as needed.

5. Surface Treatment

Anodizing: To enhance the corrosion resistance and aesthetics of the aluminum lampshade, anodizing can be performed. Anodizing not only increases surface hardness but also offers a variety of colors for enhanced decorative effect.

Coating: Some lampshades are coated for added protection and decorative effect. Coatings include anti-static, dust-proof, and anti-fingerprint layers to enhance the performance of the lampshade.

6. Assembly and Inspection

Assembly: The finished aluminum lampshade is assembled with the other components of the lamp. During assembly, secure connections and electrical safety must be ensured.

Inspection: After assembly, the lampshade undergoes a thorough inspection to ensure its quality and performance. The main inspection items include surface smoothness, dimensional accuracy, coating uniformity and electrical safety.

Key Considerations When Choosing Aluminum Circles for Lighting

Surface Smoothness: Should be free from flow lines, oxidation spots, cracks, scratches, or oil marks.

Material Quality: No rust, stains, dents, edge damage, bending, or other defects.

Reflectivity & Finish: Choose anodized or polished discs for maximum light reflection.

Thickness & Diameter Accuracy: Ensure tolerances match lamp design requirements.

No.14 Waihuan Road, CBD, Zhengzhou, China

No.14 Waihuan Road, CBD, Zhengzhou, China +86-18703635966

+86-18703635966

+86-18703635966

+86-18703635966

sales@alummc.com

sales@alummc.com

8618703635966

8618703635966