-

-

5083 Aluminum Circle Discs

- Alloy 5083

- Temper O, H12, H14, H18, H24, H32, H112, etc.

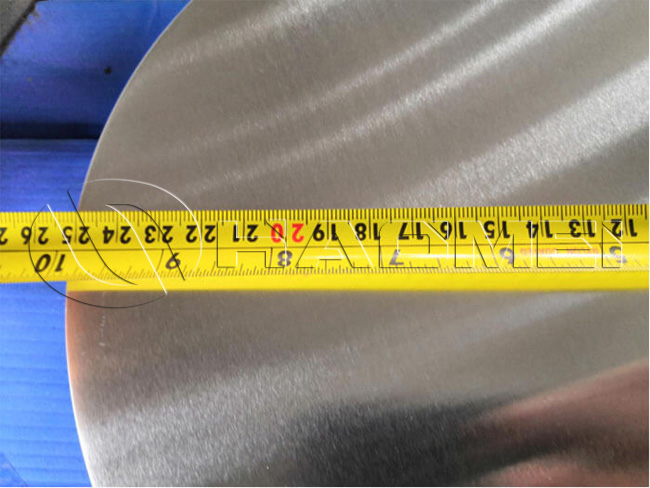

- Thickness 0.2-6.0 mm

- Diameter 50-1600 mm

- Processing Hot rolled (DC) or cold rolled (CC)

- MOQ 1-3 tons

What is a 5083 Aluminum Circle Disc?

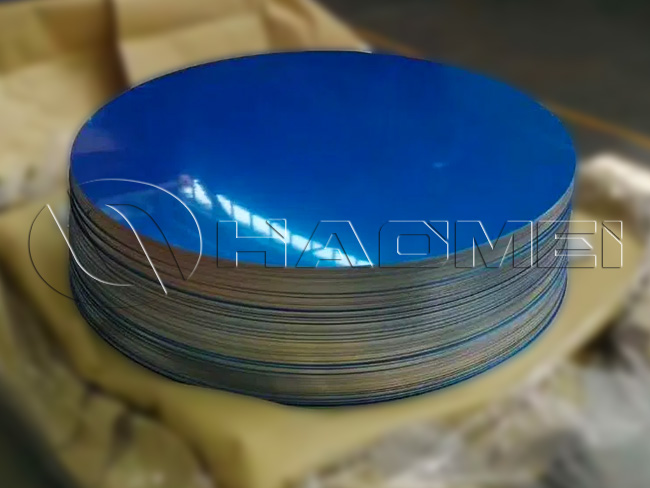

5083 aluminum circle discs are circular sheet products made from 5083 aluminum alloy through rolling, CNC cutting, or stamping processes. They belong to the 5xxx series aluminum-magnesium (anti-rust aluminum) family and are recognized as a “high-strength grade” within this series.

Their core advantage lies in significantly improved strength and fatigue resistance while maintaining the excellent corrosion resistance of the 5xxx alloys. This makes 5083 aluminum circles particularly suitable for medium- and heavy-duty applications in harsh environments-widely used in shipbuilding, marine engineering, and heavy machinery industries.

Common Tempers

O temper: Fully annealed, with the best ductility (elongation ≥15%), suitable for deep drawing and complex stamping (e.g., irregular load-bearing discs).

H111 temper: As-rolled condition after hot rolling, offering medium strength and balanced workability, suitable for general load-bearing applications.

H32 temper: Cold worked and stabilized, offering high strength (tensile strength ≈ 300 MPa) and good fatigue resistance, ideal for vibration- and heavy-load components such as bearing housings.

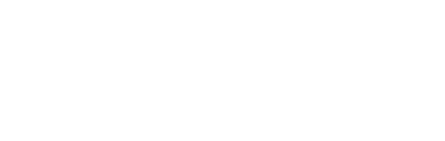

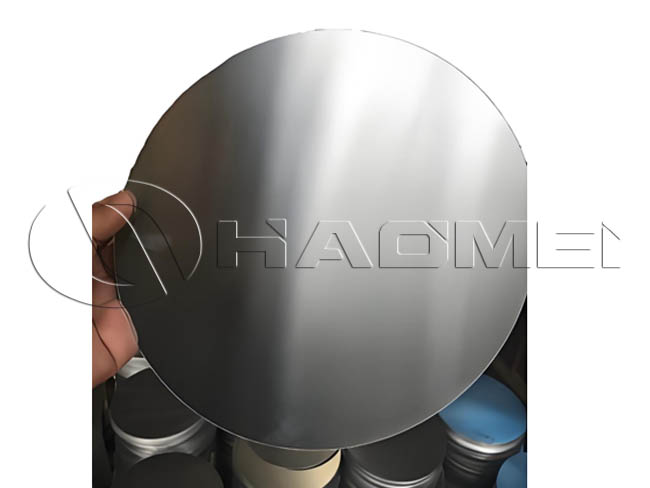

Surface Quality

Surfaces must be free of cracks, inclusions, and oxide stains.

Flatness deviation ≤0.5 mm/m (to avoid uneven stress during installation).

For corrosion-prone environments, surface roughness must be controlled (Ra ≤1.6 μm) to enhance coating adhesion.

5083 Aluminum Disc Product Information

| Alloy | 5083 |

| Temper | O, H12, H14, H18, H24, H32, H112, etc. |

| Thickness range | 0.2 mm - 6.0 mm (customizable upon request) |

| Diameter range | 50 mm - 1600 mm (customizable upon request) |

| Processing | Hot rolled (DC) or cold rolled (CC) |

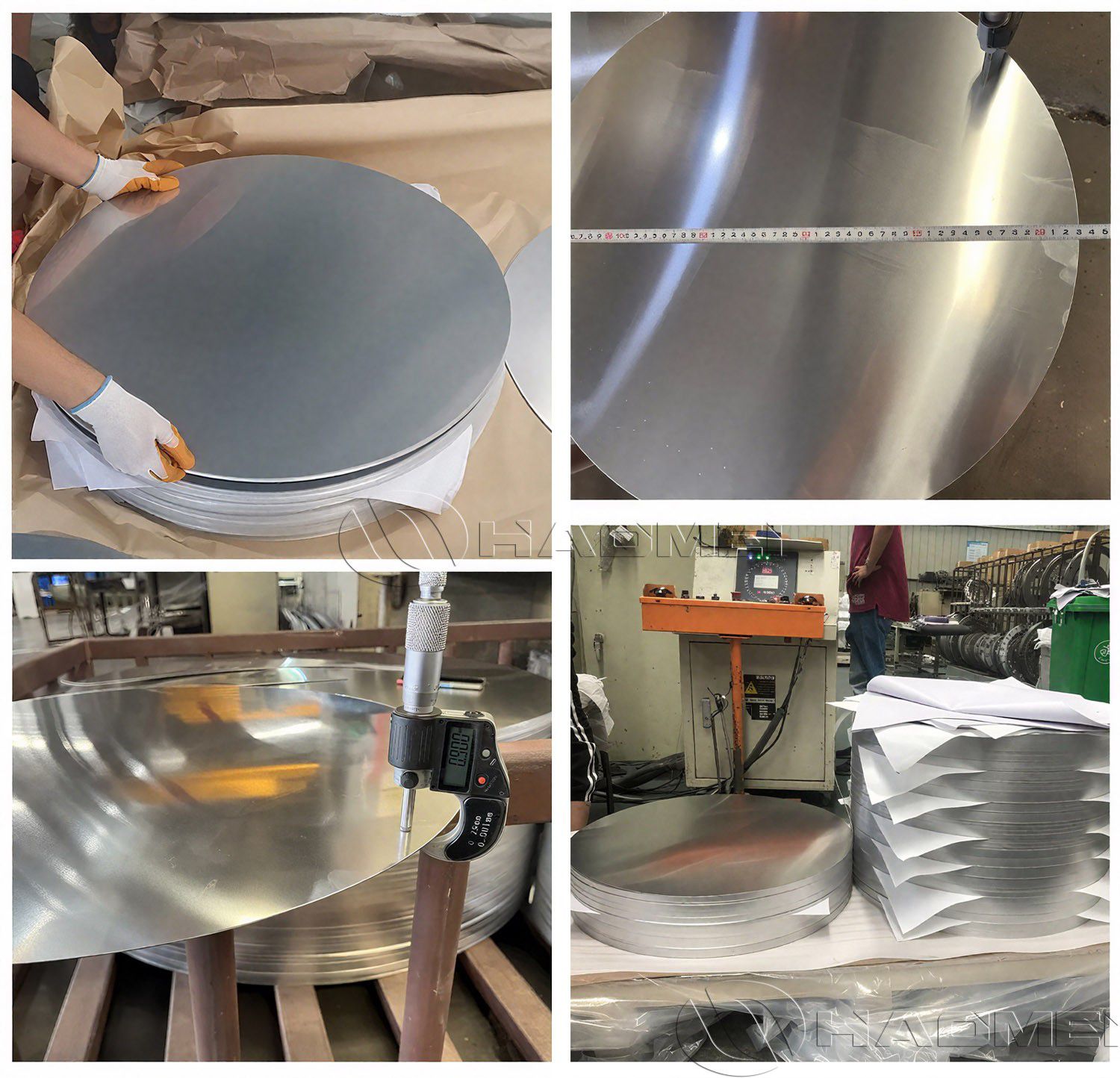

| Surface | Clean and smooth, free from scratches, pinholes, oil, or oxidation; burr-free edges |

| MOQ | 1-3 tons |

Chemical Composition (%)

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Ni | Zn | Al |

| 5083 | 0.4 | 0.4 | 0.1 | 0.4-1.0 | 4.0-4.9 | 0.05-0.25 | - | 0.25 | Remainder |

Key Properties of 5083 Aluminum Discs

Excellent corrosion resistance: Outstanding resistance against seawater, marine atmosphere, and industrial chemicals. Also highly resistant to stress corrosion cracking.

Superior weldability: One of its major advantages. Weld strength can reach over 90% of the base metal, while maintaining excellent corrosion resistance.

Medium strength & good formability: Among non-heat-treatable alloys, 5083 offers high strength while retaining good ductility. Suitable for cold forming processes such as bending and deep drawing. Also offers high fatigue strength.

Non-heat treatable: Strength is improved mainly through cold working (tempers like H111, H116, H32).

Temperature limitation: Not recommended for long-term use above 65°C (150°F), as performance may be affected.

Applications of 5083 Aluminum Round Blanks

Shipbuilding & marine industry: Hull structures, decks, side panels, and marine equipment.

Cryogenic engineering: LNG storage tanks, low-temperature equipment, and pipelines.

Transportation: Vehicle bodies, railway cars, aircraft fuel tanks, and truck bodies.

Pressure vessels: Storage tanks, chemical containers, nuclear power plant vessels, and towers.

Military vehicles: Often used for armored plates thanks to its excellent impact resistance.

Processing of 5083 Aluminum Discs

Rolling: Cold rolled to required thickness (typically 1-20 mm; heavy plates can be customized up to 50+ mm). Reduction rate must be controlled to avoid cracking due to high magnesium content.

Temper adjustment: According to needs:

O temper (fully annealed, high ductility, suitable for deep drawing).

H tempers (H111, H112, H32) via cold work or partial annealing to increase strength.

Surface pretreatment: Alkaline cleaning to remove rolling oil, acid pickling to remove oxides, optional passivation to form a protective film against oxidation.

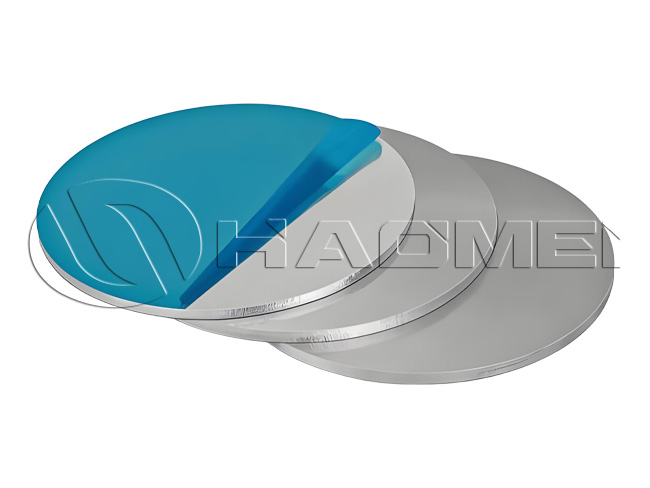

Circular cutting: CNC laser cutting (for thick plates, precision ±0.1 mm) or precision stamping (for thin plates). High-hardness dies required due to the alloy’s higher strength, preventing burrs or deformation.

Optional finishing: Edge chamfering (to avoid sharp edges), anodizing (for surface hardness and corrosion resistance, available in natural or gray finishes), coating (for outdoor or chemical environments), sandblasting (for matte, anti-slip surfaces).

5000 Series Aluminum Discs

5083 alloy is part of the 5000 series, renowned for corrosion resistance. Other alloys include 5052, 5754, and 5086, each offering unique characteristics.

Difference Between 5083 and 5754 Aluminum Discs

When selecting aluminum discs, 5083 and 5754 are often compared. Both are high-magnesium alloys, but there are key differences:

Magnesium content & strength: 5083 contains about 4.0%-4.9% Mg, significantly higher than 5754 (2.6%-3.6%), making 5083 one of the strongest alloys in the 5xxx series.

Application fields: 5083, with its superior strength and marine corrosion resistance, is ideal for heavy structural parts and marine-grade uses. In contrast, 5754 is a medium-strength option, more commonly applied in automotive bodies and general-purpose pressure vessels where strength requirements are lower.

No.14 Waihuan Road, CBD, Zhengzhou, China

No.14 Waihuan Road, CBD, Zhengzhou, China +86-18703635966

+86-18703635966

+86-18703635966

+86-18703635966

sales@alummc.com

sales@alummc.com

8618703635966

8618703635966