No.14 Waihuan Road, CBD, Zhengzhou, China

No.14 Waihuan Road, CBD, Zhengzhou, China

+86-18703635966

+86-18703635966

No.14 Waihuan Road, CBD, Zhengzhou, China

No.14 Waihuan Road, CBD, Zhengzhou, China

+86-18703635966

+86-18703635966

Traffic sign manufacturers and converters often face avoidable production issues before the blank ever reaches the printing or reflective sheeting stage. Common problems include inconsistent flatness that causes wrinkling during lamination, edge defects that telegraph through reflective films, and temper mismatches that lead to cracking during spinning or deep drawing. Outdoor exposure then adds another layer of risk: insufficient corrosion resistance or poor surface quality can reduce long-term appearance and adhesion reliability.

Using the right aluminum circular blanks for traffic signs is a practical way to control these variables. In overseas supply chains, where buyers may need stable forming performance and predictable finishing behavior across multiple batches, the selection of alloy and temper becomes the main lever for reducing scrap, rework, and field complaints.

Aluminum is widely used for road sign blanks because it balances corrosion resistance, low weight, and fabricability. Compared with heavier substrates, it simplifies installation and reduces transport cost. Compared with coated steels, it generally offers easier forming and better resistance to edge corrosion when properly processed.

For circular signs and round sign components, aluminum circles and discs also support efficient, automated workflows. Blanks can be fed into stamping, forming, rim rolling, and punching processes with consistent geometry. For reflective sign faces, a stable substrate helps maintain adhesion and appearance, especially when the manufacturing process includes surface cleaning, pretreatment, and film lamination.

The alloys most commonly specified for aluminum circle for road signs fall into two families:

1xxx series (1050, 1060, 1070, 1100): commercially pure aluminum grades emphasizing corrosion resistance, high thermal and electrical conductivity, and excellent forming.

3xxx series (3003): aluminum-manganese alloy offering higher strength than 1xxx while retaining good formability and corrosion resistance.

1050 is a high-purity aluminum alloy often selected where maximum formability and consistent surface response are important. For traffic sign blanks, it is typically used when deep drawing, rim forming, or tight bending radii are involved. Its corrosion resistance supports outdoor exposure, and its softness in annealed tempers can help reduce cracking risk.

Product context terms used by buyers often include 1050 aluminum circle and traffic sign disc blanks. For sourcing references, many buyers compare 1050 Aluminum Circle offers based on surface finish, flatness, and edge quality.

1060 is another common choice for aluminum circular blanks for traffic signs. It is frequently used when buyers want a balance between purity-driven corrosion resistance and slightly improved mechanical stability compared with lower-purity options. 1060 is widely specified for sign substrates that will be cut, punched, or lightly formed.

In procurement documentation, it is often described as 1060 aluminium circle for road signs. For typical product references, 1060 Aluminium Circle is usually evaluated for blanking quality, coil-to-disc consistency, and suitability for pretreatment and reflective sheeting.

1070, with higher purity than many general-purpose grades, is valued for excellent corrosion resistance and strong forming behavior. In traffic sign production, it may be selected for applications that demand stable surface characteristics and highly consistent forming response, especially when downstream processes include multi-step forming.

1100 is a widely used commercially pure alloy known for good corrosion resistance and workability. It can perform well in general sign blank production where forming demands are moderate and consistent surface quality is required for coatings or laminations.

3003 introduces manganese as the principal alloying element, improving strength compared with 1xxx alloys while preserving good corrosion resistance. For traffic signs, 3003 aluminum disc blanks are often chosen when added dent resistance or rigidity is desired, such as for larger diameters, thinner gauges (where stiffness is needed), or signs exposed to higher wind loads.

However, because 3003 is stronger, temper selection becomes more critical. If a process includes aggressive forming, an overly hard temper can increase the risk of cracking. Proper matching of temper to forming operations is therefore a key purchasing requirement.

Traffic signs operate in rain, salt spray (coastal roads), de-icing environments, and industrial atmospheres. 1xxx alloys and 3003 are generally chosen because they resist general corrosion well in typical outdoor conditions. For buyers, the practical focus is often on preventing cosmetic degradation and maintaining substrate integrity, including edges and punched areas.

Reflective films and coatings are sensitive to:

Scratches and roll marks that can show through

Oil residues that interfere with adhesion

Surface non-uniformity that affects appearance

A consistent, clean surface reduces variability in pretreatment and lamination. For this reason, aluminum traffic sign blanks are often specified with controlled surface condition and packaging that minimizes transport damage.

Flatness affects both processing and final appearance. Blanks that are out of flat can cause:

Poor contact during lamination

Difficulty in automated feeding

Edge lift after forming

Residual stress can also lead to distortion after punching or rim rolling. Buyers commonly request tight flatness control for reflective sign blanks, particularly for larger diameters.

Clean punching depends on suitable temper and stable mechanical properties. Overly soft material can burr or deform; overly hard material can increase tool wear and create microcracks near holes. For sign blanks requiring mounting holes, consistent temper across batches improves line stability.

Many circular signs include formed edges for stiffness and safety. Alloy and temper choices strongly influence:

Crack resistance at the rim

Springback behavior

Dimensional repeatability

1xxx alloys in softer tempers generally provide higher forming margins. 3003 can offer better final rigidity when formed correctly.

While specific adhesive systems vary by region, most reflective sheeting workflows involve cleaning and pretreatment steps. A stable aluminum substrate with predictable surface behavior supports consistent bonding and reduces risks of delamination caused by contamination or uneven surface characteristics.

Temper selection is often as important as alloy selection for aluminum circle for traffic signs. The most commonly encountered tempers in sign blank supply include:

Characteristics: softest condition, highest ductility.

Typical scenarios: deep drawing, aggressive spinning, rim forming, or operations with tight radii.

Benefit for buyers: lower risk of cracking and better tolerance to forming variability.

Characteristics: increased strength and hardness versus O; H14 is generally harder than H12.

Typical scenarios: light forming, punching, or when additional rigidity is desired without going to a fully hard condition.

Buyer consideration: improved dent resistance and stiffness, but reduced forming margin.

Characteristics: higher strength, lower ductility.

Typical scenarios: parts requiring stiffness with minimal forming, or flat blanks where forming is limited.

Buyer consideration: forming operations must be conservative to avoid edge cracking.

Because temper naming and availability can vary by mill and product form, overseas buyers often specify both target temper and key processing requirements (such as rim forming depth or hole punching patterns) so the blank can be supplied with an appropriate balance of formability and stiffness.

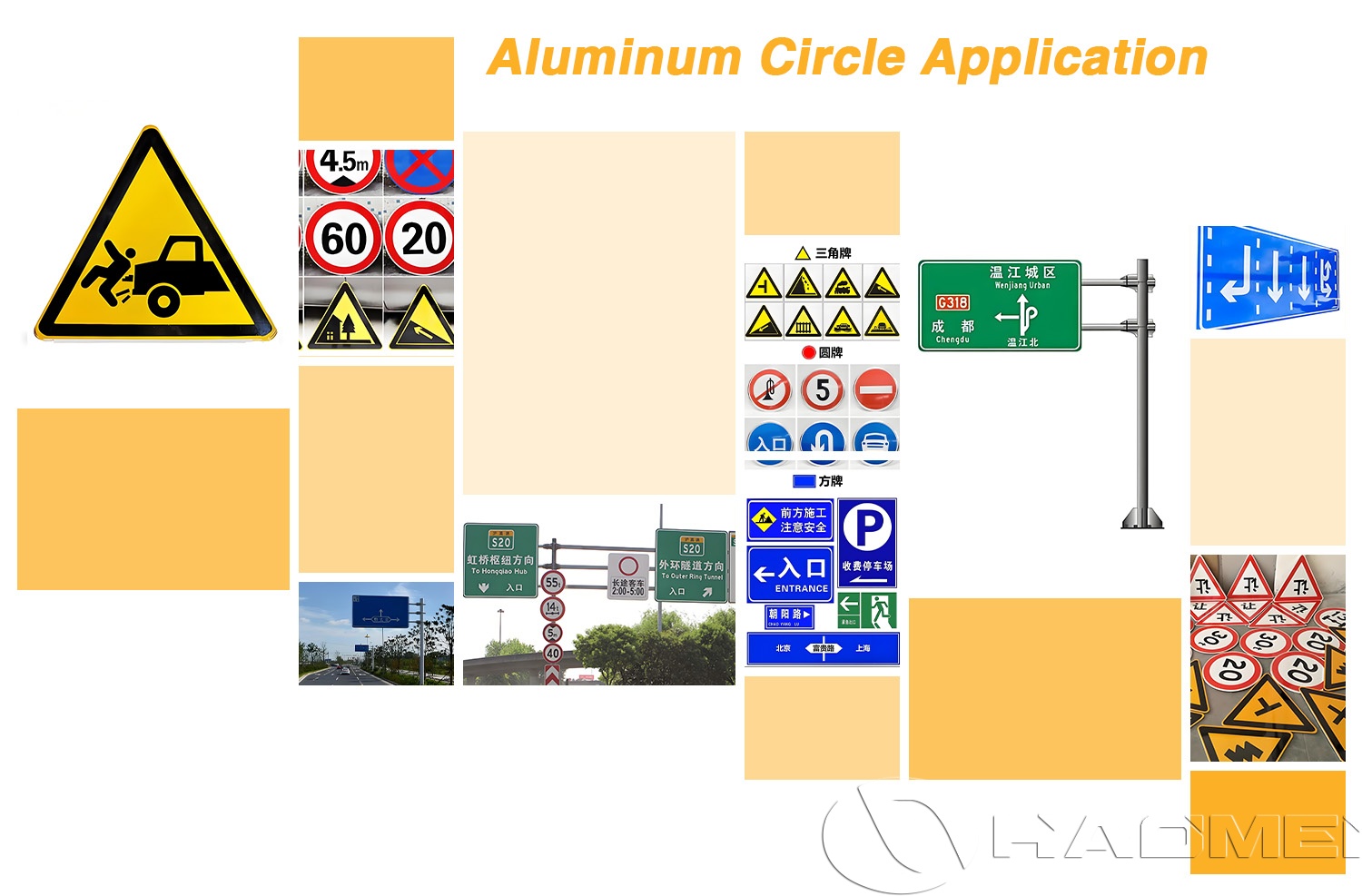

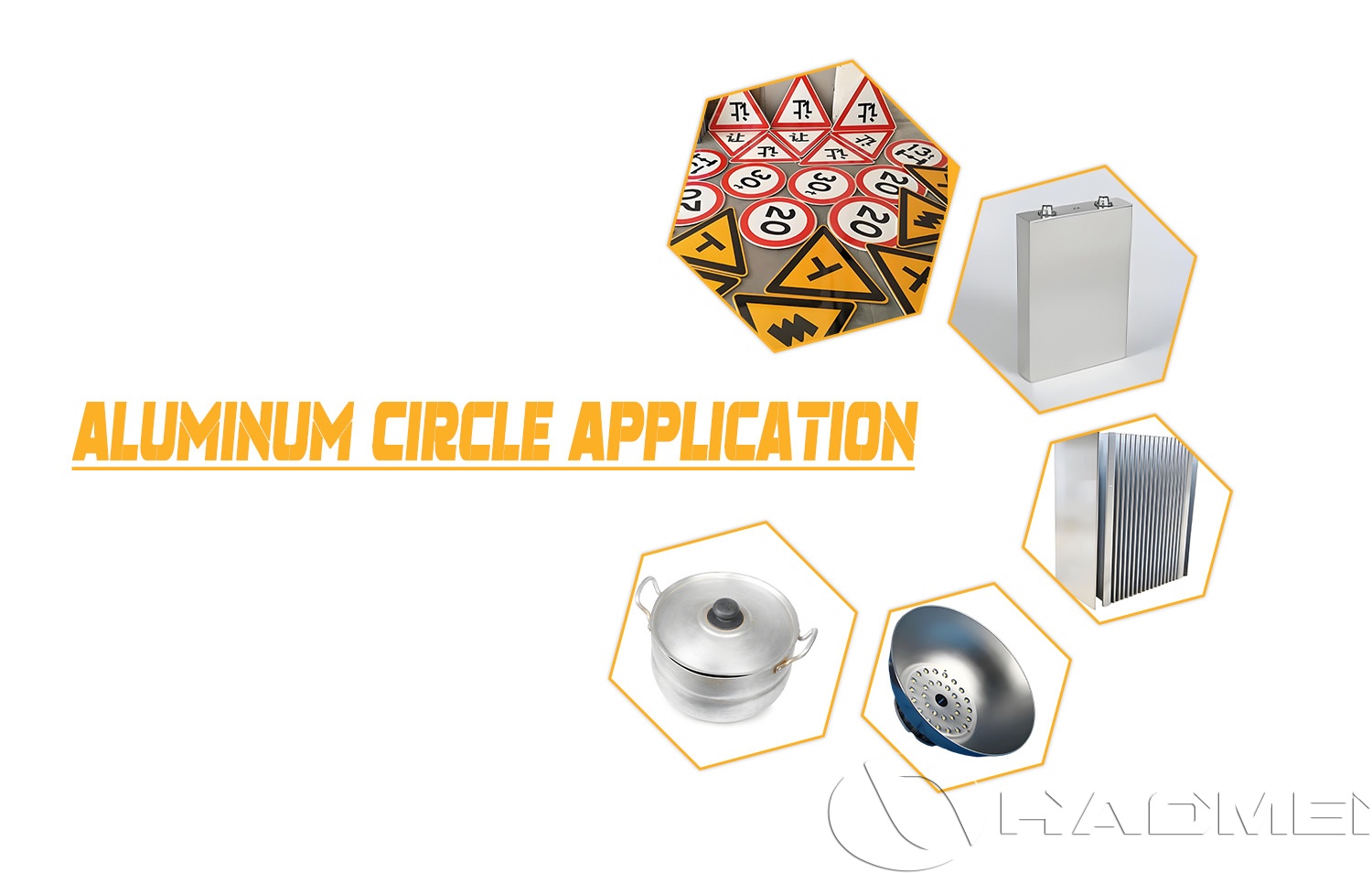

Aluminum circular blanks are commonly used for:

Round regulatory signs and warning signs

Circular backplates for reflective sign assemblies

Components requiring rim rolling for stiffness

Sign substrates requiring multiple punched holes

Outdoor labels and circular panels where corrosion resistance is essential

In addition to direct sign faces, these alloys may also be used for related highway hardware components where lightweight and outdoor durability are required.

The parameters below are presented as commonly referenced items in international purchasing documents. Specific values and compliance depend on the agreed specification, thickness range, and supply condition, and should be confirmed in mill documentation.

| Item | What Buyers Typically Specify | Notes (No Fabricated Values) |

|---|---|---|

| Alloy | 1050, 1060, 1070, 1100, 3003 | Selected based on formability, strength, and corrosion resistance needs |

| Temper | O, H12, H14, H16, H18 | Temper matched to forming level and stiffness requirement |

| Dimensions | Diameter, thickness, tolerance | Tolerances are project-specific and should be agreed in contract |

| Surface condition | Mill finish, controlled cleanliness | Important for coating and reflective sheeting adhesion |

| Edge quality | Slit edge, deburred edge, blanked edge requirements | Edge affects safety, lamination, and crack initiation risk |

| Identification and traceability | Heat number, batch number, inspection certificate | Often requested for consistent multi-batch supply |

| Common standards referenced | EN 573 (chemical composition), EN 485 (mechanical properties for sheet), ASTM B209 (aluminum sheet and plate) | Applicability depends on product form and buyer requirement |

From a performance standpoint:

Choose 1050, 1060, 1070, or 1100 when maximum formability, predictable finishing, and strong corrosion resistance are the primary needs, particularly for rim forming or deep drawing.

Choose 3003 when higher strength and improved rigidity are needed, especially for larger circular sign blanks or designs sensitive to denting and deformation.

In practice, many overseas buyers qualify more than one alloy to keep supply flexible. The deciding factor is often the downstream process window: how much forming is required, what surface finish is needed for reflective film performance, and how strict the flatness requirement is for automated lamination.

1050, 1060, 1070, 1100, and 3003 aluminum circular blanks for traffic signs are selected to control real manufacturing risks: cracking during forming, poor flatness during lamination, and inconsistent surface behavior that undermines reflective sheeting and coatings. The 1xxx series emphasizes corrosion resistance and forming performance, while 3003 provides higher strength and rigidity. Matching these alloys with appropriate tempers such as O for demanding forming or H12 to H18 for higher stiffness applications helps sign manufacturers achieve stable processing and durable outdoor performance.

Copyright © 2026 By HAOMEI Aluminum CO., LTD. All Rights Reserved. Sitemap