-

-

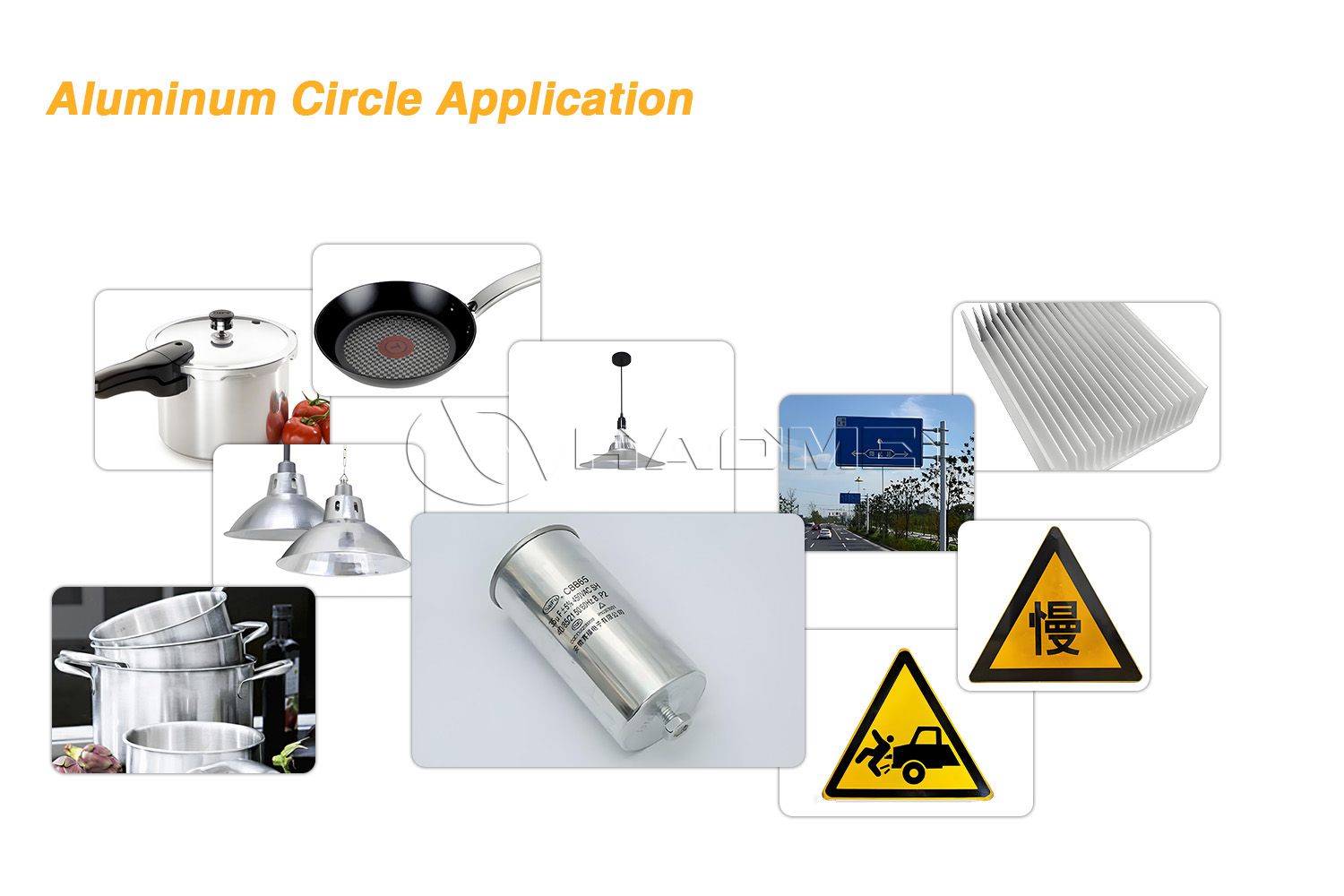

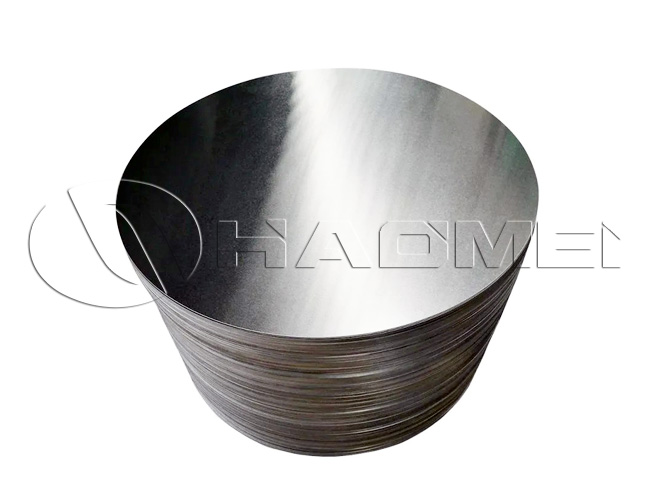

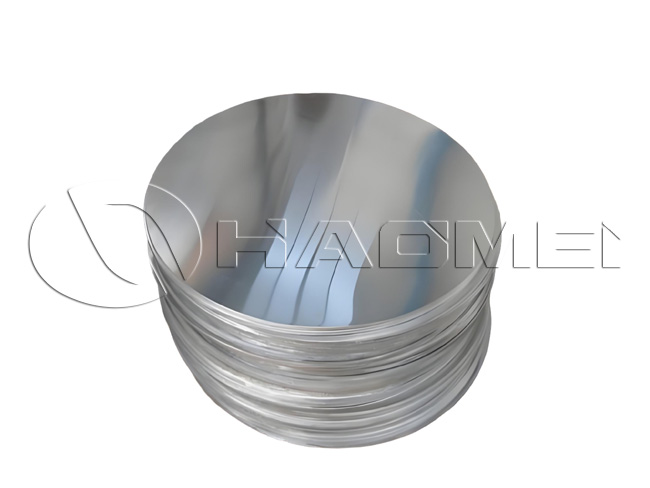

1060 Aluminium Circle

- Alloy 1060

- Thickness 0.30mm-8.00mm

- Diameter 20mm-1600mm

- Processing methods Hot rolled (DC), cold rolled (CC)

- Surface quality Free from oil, scratches, roll marks, or orange peel defects

- Sample provide

- MOQ 1-3 tons

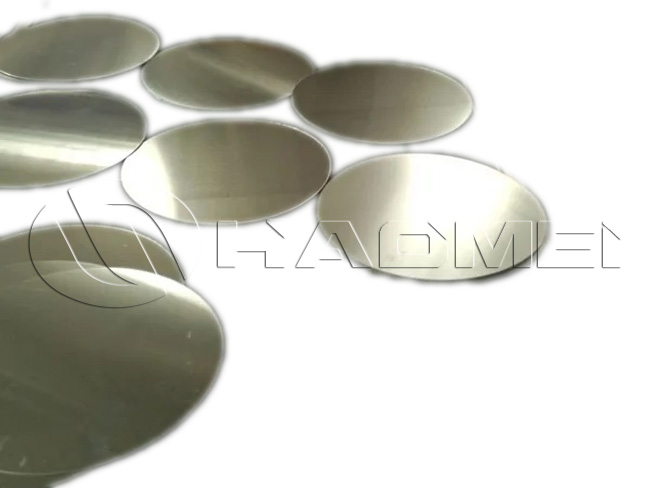

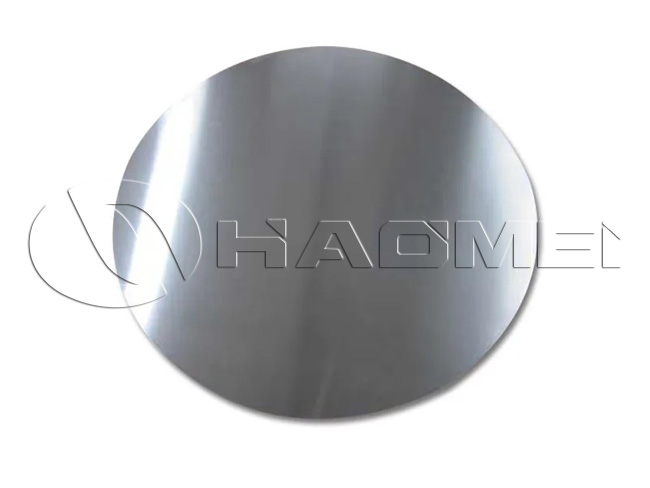

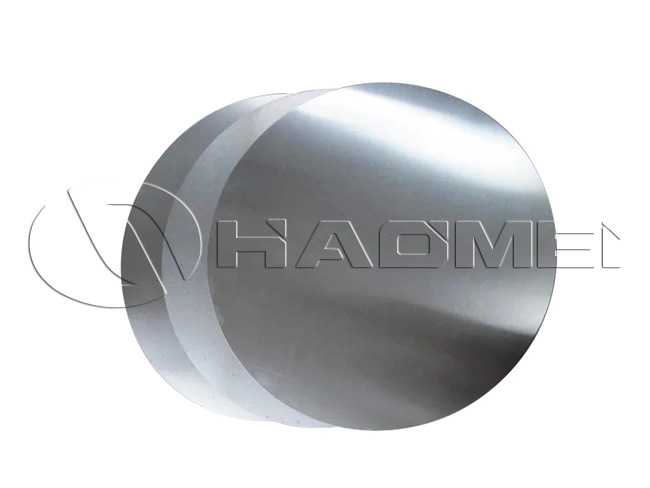

1060 aluminium circle disc is made from 1060 aluminium sheet or coil, with a purity of up to 99.6%, which is higher than 1050 aluminium circles. It features excellent formability, weldability, and corrosion resistance. The circular form is convenient for cutting and processing into various shapes, making it widely used in heat sinks, electronic packaging, container lids, and chemical and food packaging.

The surface of 1060 aluminium circles is smooth and flat, with uniform microstructure, good mechanical properties, and moderate cost. Different thicknesses and diameters can be customized as required, suitable for precision parts manufacturing.

Features of 1060 Aluminium Circles

Higher ductility: Compared with 1050, its plasticity is better, with deep drawing performance improved by about 10-15%, making it suitable for more complex forming processes.

Excellent electrical and thermal conductivity: Conductivity ≥ 61% IACS (International Annealed Copper Standard); thermal conductivity 230 W/(m·K), superior to most aluminium alloys.

Strong corrosion resistance: Outstanding resistance in humid, weak acid, and alkaline environments; surface can be anodized for enhanced protection.

Lightweight: Density 2.7 g/cm³, same as 1050, effectively reducing component weight.

Good weldability: 1060 aluminium can be welded by common methods such as TIG and MIG, with stable performance after joining.

1060 Aluminum Wafer Product Information

| Alloy | 1060 |

| Designation | AA1060, A1060, 1060A, Al99.6 |

| Temper | O, H12, H14, H16, H18, etc. |

| Thickness range | 0.30mm-8.00mm |

| Diameter range | 20mm-1600mm |

| Thickness tolerance | ±0.02mm |

| Diameter tolerance | ±1mm |

| Hardness | 20HB-35HB |

| Standards | GB/T 3880-2012, ASTM B209 |

| Processing methods | Hot rolled (DC), cold rolled (CC) |

| Surface finish | Polished, anodized, color coated, non-stick |

| Surface quality | Free from oil, scratches, roll marks, or orange peel defects |

| Applications | Cooking, baking, kitchenware, signage, etc. |

| MOQ | 1-3 tons |

1060 Aluminium Chemical Composition (%)

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Ni | Zn | Ca | V | Ti | Other | Al |

| 1060 | 0.25 | 0.35 | 0.05 | 0.03 | 0.03 | - | - | 0.05 | - | 0.05 | 0.03 | 0.03 | 99.6 |

1060 Aluminium Circle Mechanical Properties

| Alloy | Temper | Thickness (mm) | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) | Hardness(HV) |

| 1060 | O | >0.2-0.5 | 60-100 | ≥15 | ≥20 | 20-30 |

| >0.5-1.0 | ≥30 | |||||

| >1.0-4.0 | ≥35 | |||||

| H22 | >0.2-0.5 | 80-120 | ≥60 | ≥12 | 30-40 | |

| >0.5-1.0 | ≥15 | |||||

| >1.0-4.0 | ≥18 | |||||

| H24 | >0.2-0.5 | 95-135 | ≥70 | ≥6 | 35-45 | |

| >0.5-1.0 | ≥8 | |||||

| >1.0-4.0 | ≥10 | |||||

| H26 | >0.2-0.5 | 110-155 | ≥75 | ≥2 | 43-55 | |

| >0.5-1.0 | ≥4 | |||||

| >1.0-4.0 | ≥6 | |||||

| H18 | >0.2-0.5 | ≥125 | ≥85 | ≥2 | 50-65 | |

| >0.5-1.0 | ≥3 | |||||

| >1.0-4.0 | ≥4 |

Physical Properties

| Density | 2.71 g/cm³ |

| Melting point | 640°C |

| Elastic modulus | 73 GPa |

| Thermal conductivity | 121–193 W/m·K |

| Thermal expansion | 21.1 × 10⁻⁶/K |

| Electrical conductivity | 61% IACS |

| HS code | 7606.9100 |

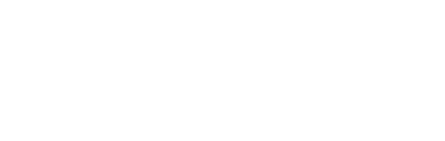

Main Applications of 1060 Aluminium Circle

Lighting industry: Used for lamp reflectors, lamp covers, and radiators. Its high reflectivity and thermal conductivity make it ideal for LED lighting.

Cookware manufacturing: Pressure cookers, non-stick pans, steamers, and other cookware parts. Its high thermal conductivity ensures fast and even heat transfer, improving cooking efficiency.

Traffic signs: Widely used in traffic signs and reflective boards due to its corrosion resistance and easy processing.

Electronics and electrical appliances: For capacitor casings, heat sinks, and other parts requiring high electrical and thermal conductivity.

How is 1060 Aluminium Circle Produced?

The production of 1060 aluminium circles mainly adopts automated stamping processes. With 1060 aluminium coil/sheet (Al ≥ 99.6%) as raw material, the process includes decoiling, blanking, and stamping through fully automatic lines. According to requirements, annealing (such as O temper or H24) and surface treatments can be applied to meet deep drawing, bending, and other processing needs. The final discs are precise in size, free from scratches, and ready for cookware, lighting, traffic sign, and packaging applications. The process is efficient and generates minimal waste.

How to Choose the Right 1060 Aluminium Circle?

When choosing 1060 aluminium circles, thickness, diameter, and temper should match the intended application and forming process:

For deep drawing or spinning with large deformation, O temper with excellent ductility is recommended to prevent cracking.

For applications requiring higher strength, H14 or H24 tempers are suitable.

Surface finish, dimensional accuracy, and uniformity should also be considered to ensure smooth processing and desirable final product performance.

Differences Between 1050 and 3003 Aluminium Circles

1060 vs. 3003 aluminium circle:

3003 aluminium circles are harder than 1060 ones (30-35HB vs. 20-30HB). However, 1060 aluminium circles contain more aluminium (>99.6%), making them softer by about 10%. 3003 aluminium circles are often used for high-grade cookware such as pressure cookers and non-stick pans, while 1060 aluminium circles are mainly used in general cookware such as pots, frying pans, kettles, and trays.

1060 vs. 1050 aluminium circle:

Both belong to the 1000 series, but the aluminium content differs. 1060 has higher purity (99.6% vs. 99.5%) and lower iron content (0.35% vs. 0.4%). Its strength is slightly higher (tensile strength 110-136 MPa vs. 60-100 MPa). The production of 1060 circles also involves adding Al-Ti-B wire for grain refinement, improving material uniformity.

No.14 Waihuan Road, CBD, Zhengzhou, China

No.14 Waihuan Road, CBD, Zhengzhou, China +86-18703635966

+86-18703635966

+86-18703635966

+86-18703635966

sales@alummc.com

sales@alummc.com

8618703635966

8618703635966