No.14 Waihuan Road, CBD, Zhengzhou, China

No.14 Waihuan Road, CBD, Zhengzhou, China

+86-18703635966

+86-18703635966

No.14 Waihuan Road, CBD, Zhengzhou, China

No.14 Waihuan Road, CBD, Zhengzhou, China

+86-18703635966

+86-18703635966

Frying pan programs often run into predictable production and quality issues: inconsistent forming during stamping or deep drawing, orange peel or surface defects after anodizing or coating, distortion during spinning, and premature denting in distribution or end use. These problems typically trace back to two root causes: material selection that does not match the forming route, and temper choice that does not balance ductility, strength, and dimensional stability.

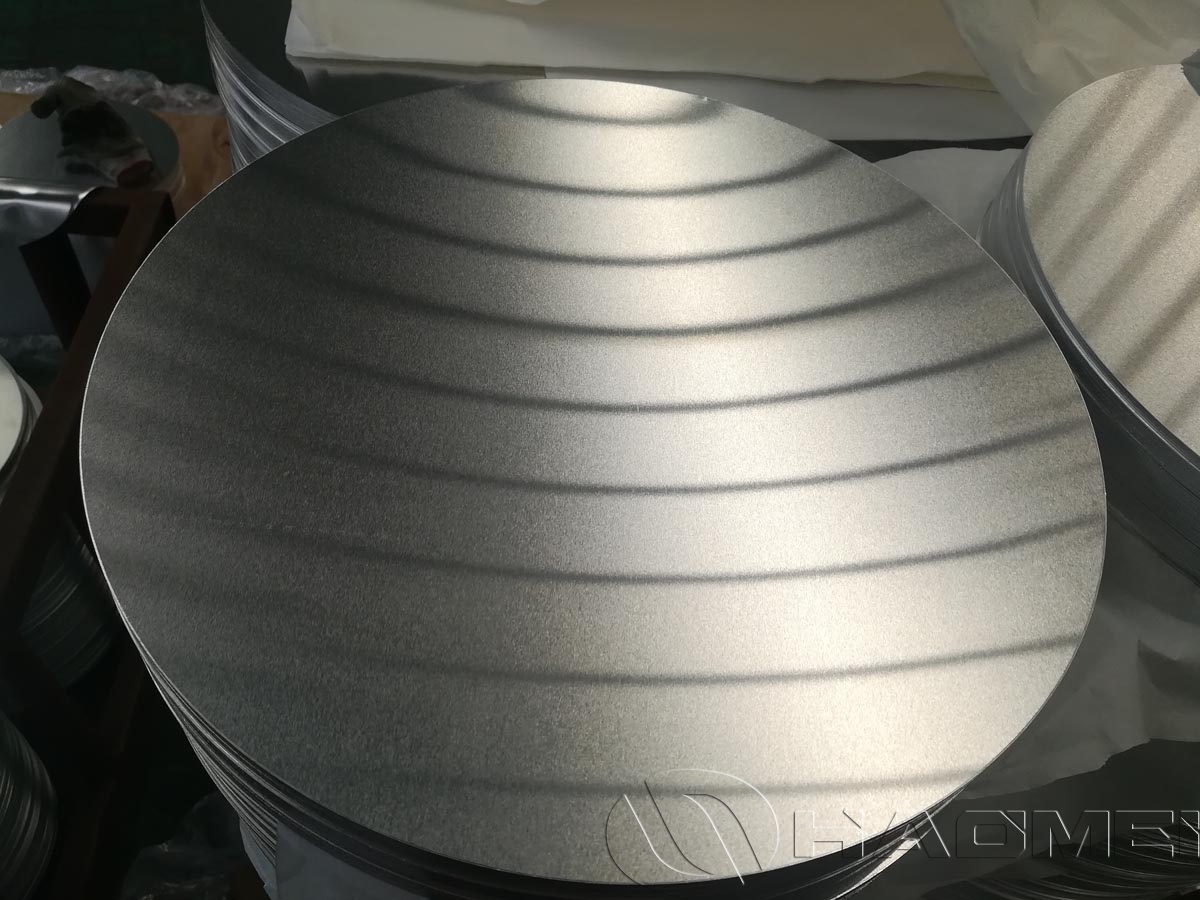

For many overseas cookware buyers, 3003 aluminum discs have become a practical baseline for reliable pan manufacturing. The alloy is widely used for aluminum circles and discs because it offers a stable combination of formability, corrosion resistance, and surface performance for common cookware finishing processes. This article explains why 3003 aluminum disc stock supports better frying pan outcomes, how temper affects processing behavior, and where this alloy fits among typical cookware applications.

Even with capable presses and well-designed tooling, frying pan production can suffer when the disc material is not optimized for the process window.

Cracking at the rim during deep drawing, often linked to insufficient elongation or an over-hardened temper.

Wrinkling during drawing or spinning, often related to low yield strength, excessive blank holder pressure variation, or poor lubrication compatibility with the disc surface.

Earing, which increases trimming waste and can create thickness variation at the rim.

Uneven thickness distribution or localized thinning, especially in multi-step draws.

Surface marks that telegraph through coatings, nonstick layers, or anodized finishes.

Cookware circles are usually punched from coil and then processed through forming. Variations in grain structure, residual stress, and surface condition can become more visible in a circular blank than in flat sheet applications. For buyers sourcing discs globally, consistent metallurgy and finishing preparation are as important as nominal thickness and diameter.

3003 is an Al-Mn alloy, commonly selected when manufacturers need a dependable balance of formability and moderate strength without the higher cost or narrower forming window of stronger alloys.

Good formability for stamping, deep drawing, and spinning when the correct temper is used.

Corrosion resistance suitable for typical kitchen environments and common cleaning exposures.

Stable surface quality for downstream finishes such as anodizing, painting, or nonstick coating systems, provided the surface is controlled and cleaned appropriately.

Adequate mechanical robustness for handling and logistics, especially when compared with very soft, fully annealed material in thin gauges.

For many pan designs, 3003 aluminum circle blanks help reduce scrap rates by improving draw stability and limiting cracking at critical radii.

Compared with purer 1xxx series material, 3003 generally offers higher strength, which can improve dent resistance and reduce deformation during handling, while still maintaining good formability.

Compared with higher strength alloys, 3003 tends to provide a more forgiving forming window for deep drawing and spinning operations, particularly in cookware geometries with tight corner radii or multi-stage forming.

When buyers specify a 3003 Aluminum Circle, the main objective is typically predictable forming behavior at scale, rather than maximum tensile strength.

A frying pan blank must perform well across multiple steps. 3003 aluminum discs are often chosen because they remain stable across common cookware workflows.

Edge condition influences early-stage defects. A clean, burr-controlled edge helps reduce crack initiation during drawing. Disc suppliers commonly manage blanking parameters to limit edge tearing and maintain roundness, as these factors directly affect draw symmetry.

For deep-drawn frying pans, a key advantage of 3003 is its ability to undergo significant plastic deformation in softer tempers. Correct lubrication and blank holder settings remain essential, but 3003 generally provides predictable strain distribution.

Spun cookware often requires a material that tolerates cyclic deformation without surface tearing or excessive work hardening. 3003 is widely used in spinning because it can balance ductility and strength, particularly when partially work-hardened tempers are selected for better shape retention.

Cookware discs frequently proceed to mechanical finishing, chemical cleaning, and then coating or anodizing. Surface uniformity matters because minor defects can telegraph through thin nonstick systems or appear as color variation in anodized layers. 3003 is commonly selected because it can provide consistent finishing results when the upstream rolling and annealing are well controlled.

Temper selection is not a minor detail for cookware circles. It changes how the disc behaves in drawing, spinning, trimming, and final assembly operations.

Typical scenario: deep drawing of deeper cookware shapes or multi-step draws.

Why it is used: O temper offers higher ductility and is more tolerant of tight radii and significant deformation.

Practical trade-off: lower strength can increase the risk of handling dents or distortion if the design is very thin or if the supply chain is rough.

O temper is commonly considered when cracking risk is the primary concern and when the pan geometry requires aggressive forming.

Typical scenario: shallow to medium-depth draws, spinning where better rigidity is helpful, or designs needing improved dent resistance.

Why it is used: these tempers increase strength compared with O temper while still allowing forming in many cookware shapes.

Practical trade-off: reduced ductility compared with O temper can narrow the process window, especially for deep draws with tight corner radii.

In many commercial frying pan lines, 3003 H14 aluminum disc stock is used when the pan geometry and forming steps are moderate and the producer wants better shape stability.

Typical scenario: components that require less forming but benefit from higher stiffness, or where flattening and rigidity are priorities.

Practical trade-off: these tempers are generally less suitable for deep drawing and may increase the likelihood of splitting if significant deformation is required.

For frying pan bodies that require deep draws, these harder tempers are typically evaluated cautiously and only where forming demands are limited.

Although cookware is a primary driver, buyers often source the same alloy for other formed products because the forming and surface requirements overlap.

Common applications include:

Cookware bodies: frying pans, saute pans, saucepans, and lids (depending on design and forming route).

Lighting reflectors and lampshades where spinning and surface appearance are important.

Sign blanks and general circular formed parts requiring corrosion resistance and consistent finishing.

When a procurement team is standardizing across multiple product lines, referencing a broader family such as 3000 Series Aluminum circle can help align specifications across similar Mn-alloy options while keeping forming behavior in focus.

For international sourcing, the goal is to translate end-use requirements into controllable material attributes.

Disc thickness and thickness consistency, which affects draw ratio capability, heat distribution in use, and flatness.

Diameter tolerance and roundness, which affect draw symmetry and earing control.

Surface condition appropriate for the intended finish (nonstick coating, anodizing, or painting).

Edge quality from blanking and any deburring requirements.

Temper selection aligned to the forming process, especially for deep drawing or spinning.

A stable supply program typically relies on consistency batch-to-batch more than on pushing extreme forming limits.

The table below lists commonly requested documentation and widely referenced standards categories in global aluminum trade. Specific values and certifications depend on the supplier, the product form, and the order contract, and should be confirmed in mill documentation.

| Item | What it Covers | Notes for Cookware Discs |

|---|---|---|

| Alloy designation: AA 3003 | Chemical composition category for 3003 alloy | Typically specified as 3003 for circles/discs used in forming applications |

| Temper designation (for example, O, H12, H14) | Metallurgical condition affecting formability and strength | Temper should match deep drawing vs spinning needs; confirm on test certificate |

| Dimensional inspection records | Thickness, diameter, flatness, roundness | Supports tooling stability and reduces forming variability |

| Material test certificate (MTC) | Batch traceability, reported tests as supplied | Content and test scope vary by supplier and agreed specification |

| RoHS or REACH statements (when requested) | Regulatory declarations for restricted substances | Often requested for consumer-facing goods supply chains; applicability depends on the buyer and market |

Better frying pans start with fewer forming defects and more stable surface outcomes. 3003 aluminum discs are widely used because the alloy provides reliable formability, good corrosion resistance, and consistent finishing performance for common cookware processes. Selecting the right temper is central: O temper prioritizes deep draw ductility, while H12 and H14 tempers often balance formability with improved rigidity and handling resistance. For overseas buyers, clear alignment between pan geometry, forming route, finish requirements, and disc temper is the practical path to consistent production quality.

Copyright © 2026 By HAOMEI Aluminum CO., LTD. All Rights Reserved. Sitemap