No.14 Waihuan Road, CBD, Zhengzhou, China

No.14 Waihuan Road, CBD, Zhengzhou, China

+86-18703635966

+86-18703635966

No.14 Waihuan Road, CBD, Zhengzhou, China

No.14 Waihuan Road, CBD, Zhengzhou, China

+86-18703635966

+86-18703635966

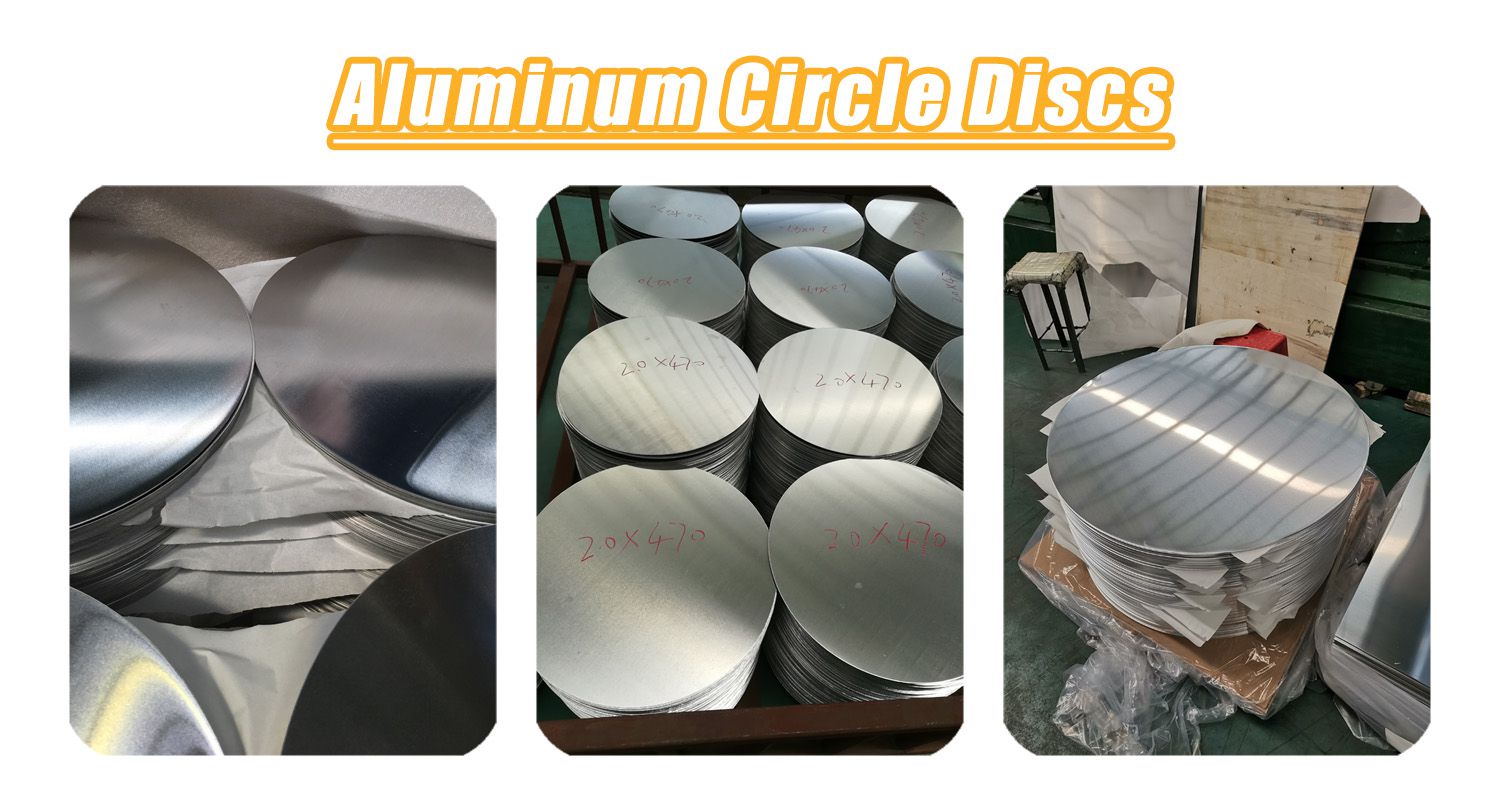

HAOMEI Aluminum is a professional manufacturer of aluminum circles. Our main products include aluminum circles, aluminum discs, aluminum sheets, round aluminum plates, cookware aluminum circles, traffic sign aluminum circles, DC/CC aluminum circles, anodized products, etc. Our aluminum circles are widely used in the production of cookware, tableware, pizza pans, pressure cookers, baking trays, road signs, traffic signs, and more.

We mainly produce 1 series, 3 series, 5 series, 6 series, and 8 series pure aluminum. Alloy grades include 1050, 1060, 1100, 1200, 3003, 5052, 8011, etc. We provide high-quality aluminum discs with thicknesses from 0.3mm to 4mm and diameters from 80mm to 1600mm to meet your requirements.

| Grades | 1050, 1060, 1070, 1100, 3003, 3004, 3005, 3105, 4006, 5052, 5082, 5754, 8011, etc. |

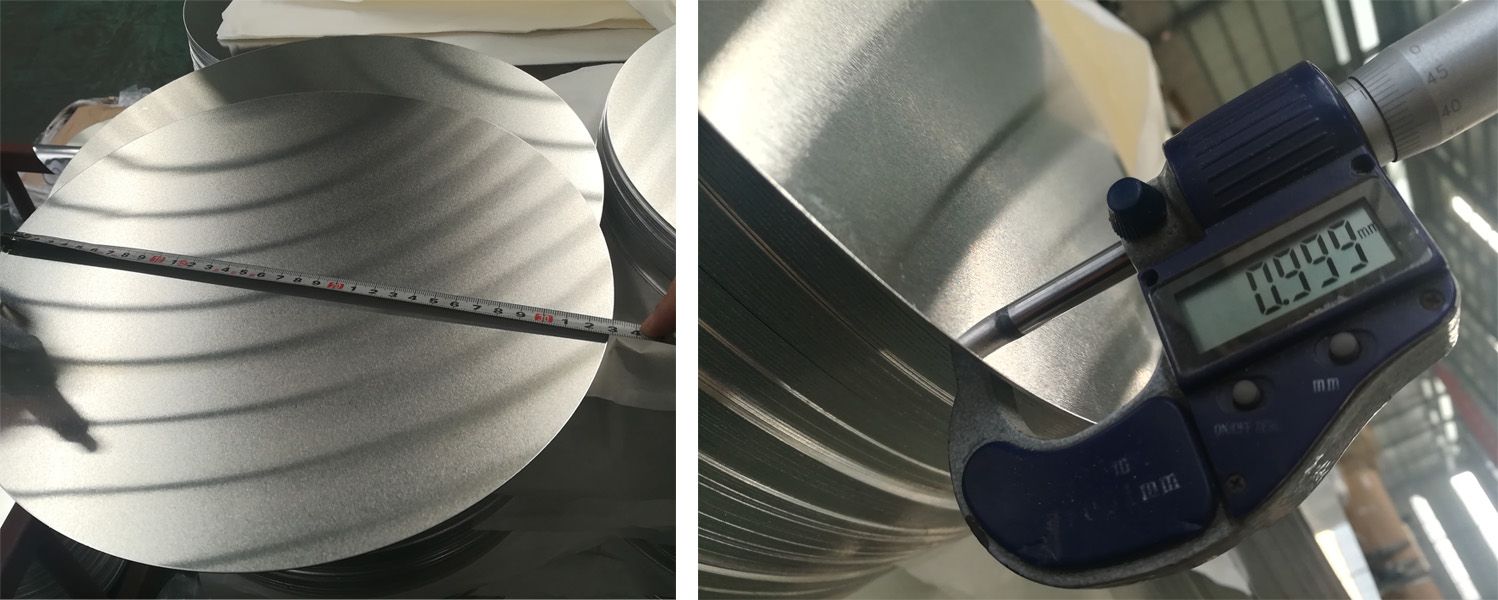

| Thickness | 0.8mm - 5.0mm |

| Diameter Range | 180mm - 1000mm |

| Temper | O, H2, H4, H*6, H18, H111, H112, etc. |

| Production Process | CC or DC |

| Surface Treatment | anodizing, polishing, color coating, brushing, etc. |

| Surface Quality | flat and clean, no scratches, holes, oil stains, or oxidation; burr-free edges |

| Applications | cookware, non-stick pans, pressure cookers, traffic signs, lamp shades, heat sinks, etc. |

| Packaging | seaworthy wooden pallets or wooden cases |

| MOQ | 1-3 tons |

Excellent ductility: Suitable for deep drawing and spinning without cracking, ideal for cookware and lighting.

Lightweight & high strength: Low density with good mechanical properties, easier to transport and process.

Strong corrosion resistance: Natural oxide film protects against oxidation, acid, and alkali, suitable for kitchen and outdoor use.

High surface quality: Smooth, clean, free from oil and scratches, suitable for anodizing, electrophoresis, and coating.

Food-grade safety: Certified to meet cookware and food packaging standards.

Aesthetic appearance: Easy to polish, anodize, or paint for a perfect look.

Good thermal conductivity: Heats quickly and evenly, perfect for cookware.

Eco-friendly & recyclable: 100% recyclable, in line with sustainable development.

Smelting & casting: Aluminum ingots are melted and cast into large rectangular slabs.

Hot rolling: Slabs are heated and rolled into coils.

Cold rolling: Coils are rolled further at room temperature to the required thickness and surface finish.

Circle blanking: Cold-rolled coils are fed into circle blanking machines equipped with round dies, punching out circles like cookie cutters.

Trimming (optional): Edges are polished to remove burrs.

Annealing (optional): Circles are heated in a furnace to soften them (O temper).

By alloy series:

By surface treatment:

Anodized aluminum circles

Mirror aluminum circles

We can produce sizes from 50mm to 1360mm.

Our mold sizes include 150, 155, 160, 165 (increments of 5mm), etc.

Custom sizes available upon request.

Thanks to their lightweight, strength, corrosion resistance, deep drawing performance, and anodizing ability, HAOMEI aluminum circles are widely used in:

Cookware (pots, frying pans, pressure cookers, griddles, etc.)

Lamp reflectors

Decorative materials

Traffic signs

Packaging containers (bottle caps, cans)

Home appliance parts

Covered with plastic film and kraft paper as needed.

Packed with wooden cases or wooden pallets to prevent damage during transport.

Two packing methods available: eye-to-wall and eye-to-sky, based on customer requirements.

Typically, one package weighs 2 tons; a 20′ container loads 18-22 tons, a 40′ container loads 20-24 tons.

Q1: What is the difference between CC aluminum circles and DC aluminum circles?

CC (Continuous Casting): aluminum ingot → smelting → continuous casting → coil → circle → packing

DC (Direct Casting): aluminum ingot → smelting → slab → direct casting → coil → circle

For cookware and tableware production, if spinning is required, use CC material; if pressing (DDQ) with depth over 150mm is required, use DC material.

Q2: Can you provide samples?

A2: Yes, HAOMEI provides free samples for testing, but freight should be paid by the buyer.

Q3: What is the delivery time?

A3: 15–25 days for regular sizes; custom products depend on the order.

Q4: What is the minimum order quantity (MOQ)?

A4: For regular sizes, MOQ is usually 3 tons; flexible adjustments can be made based on customer needs.

Q5: What surface treatments do you support?

A5: We provide anodizing, coating, polishing, and painting (PE, PVDF) options.

Q6: How do you guarantee quality?

A6: HAOMEI is ISO9001 certified, products comply with ASTM, EN, JIS international standards, and every batch is strictly tested.

Q7: Which countries do you mainly export to?

A7: Our aluminum circles are exported to over 40 countries, including the USA, Canada, Germany, Italy, Turkey, UAE, India, Vietnam, etc.

Copyright © 2026 By HAOMEI Aluminum CO., LTD. All Rights Reserved. Sitemap