No.14 Waihuan Road, CBD, Zhengzhou, China

No.14 Waihuan Road, CBD, Zhengzhou, China

+86-18703635966

+86-18703635966

No.14 Waihuan Road, CBD, Zhengzhou, China

No.14 Waihuan Road, CBD, Zhengzhou, China

+86-18703635966

+86-18703635966

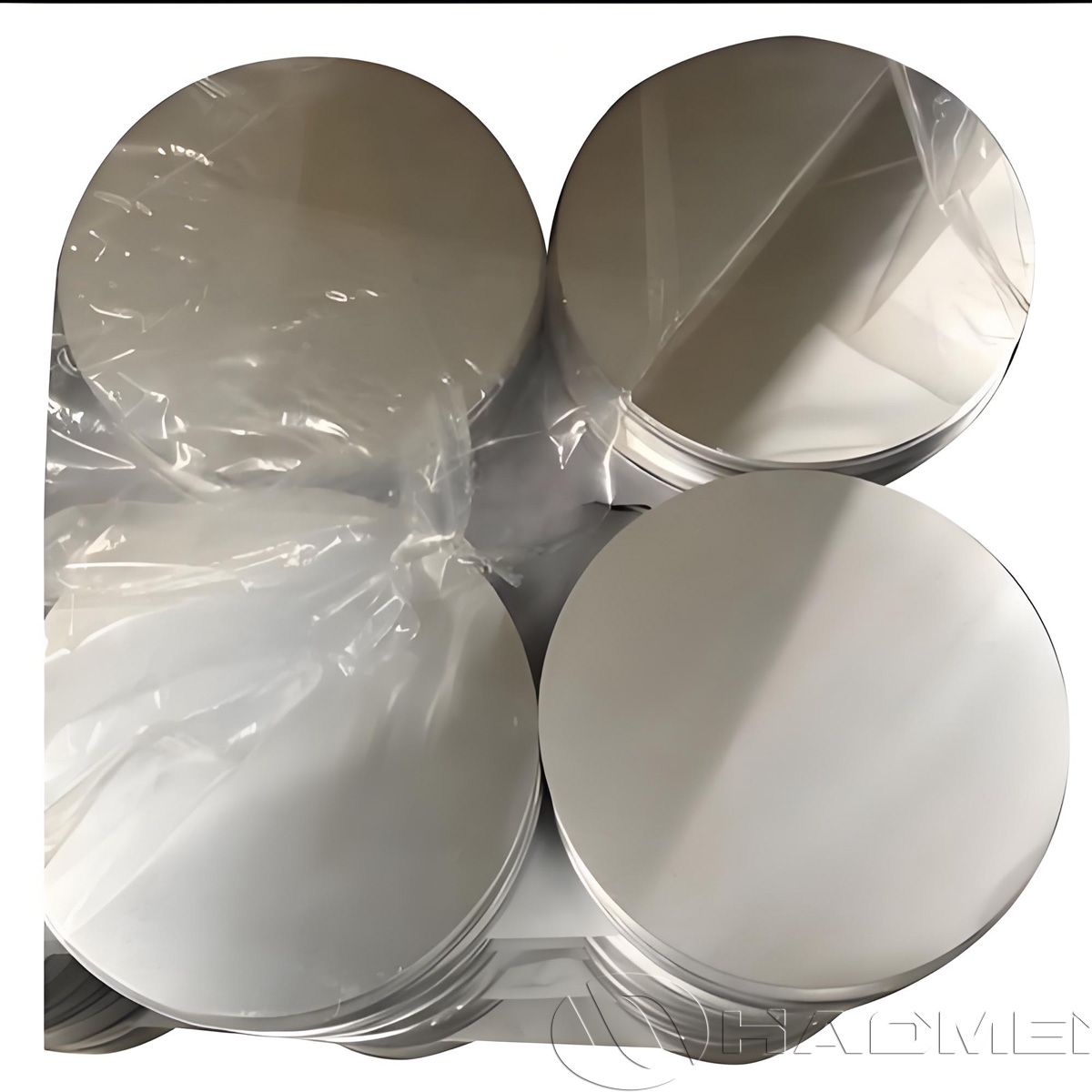

1070 aluminum circles belong to the 1000 series high-purity aluminum alloys, containing ≥99.7% aluminum. They are circular sheets produced via hot or cold rolling using high-purity aluminum. Known for excellent ductility, thermal conductivity, corrosion resistance, and workability, 1070 aluminum circles are widely used in both industrial and consumer applications.

Compared to 3003 or 5052 aluminum circles, 1070's main advantage is its high aluminum content, flexibility, and smooth, bright surface, with minimal alloying elements affecting its electrical and thermal conductivity. This makes it irreplaceable in certain specialized applications.

1070 aluminum circles, as intermediate stamping materials, are usually supplied in O temper (annealed soft) or light-hardened states such as H12/H14 to maximize plasticity, facilitating subsequent cold stamping and deep drawing.

| Alloy | 1070, AA1070 |

| Aluminum Content | ≥99.7% |

| Temper | H14, H18, H24, O |

| Thickness | 0.5-6.0 mm (customizable) |

| Diameter | 50-1200 mm (customizable) |

| Production Process | CC/DC |

| Surface Treatment | Anodizing, enamel, coating, brushed finish |

| Applications | Cookware, non-stick pans, lampshades, traffic signs |

| Sample | Available |

| Packaging | Standard export packaging |

| MOQ | 1-3 tons |

| Density | 2.71 g/cm³ |

| Thermal Conductivity | 230 W/m·K (room temperature) |

| Tensile Strength | 70-125 MPa |

| Yield Strength | 35-80 MPa |

| Elongation | 20-35% |

High Electrical Conductivity

Nearly as conductive as copper, ideal for components requiring efficient current transfer.

High Thermal Conductivity

Rapidly conducts and dissipates heat, suitable for heat dissipation components.

Excellent Plasticity

High purity allows deep drawing, stretching, and bending without cracking, essential for complex stamped products.

Good Surface Processability

Easily anodized to achieve transparent or colored oxide films, enhancing corrosion resistance and aesthetics.

Outstanding Corrosion Resistance

Forms a dense oxide layer in air, resistant to water and mild acid/alkali corrosion.

Lightweight

Density is about one-third that of steel, ideal for lightweight designs.

Cost-Effective

Long service life, low cost, and high recyclability.

Lighting and Lamp Manufacturing (Deep Drawing Applications)

Lamp Reflectors/Housings: High deep-drawing performance enables one-step stamping of complex lamp shapes. Polished and anodized surfaces provide high reflectivity, improving lighting efficiency.

LED Heat Sinks: High thermal conductivity ensures rapid heat dissipation, maintaining LED lifespan and performance.

Cookware and Tableware (Deep Drawing Applications)

Non-stick Pan Bases / Pressure Cooker Bodies: High plasticity allows seamless, uniform deep-drawn cookware.

Vacuum Flask Liners: Leverages excellent thermal conductivity and formability.

Electrical and Electronics (Conductive / Thermal Applications)

Capacitor Housings / Electronic Components: High conductivity and corrosion resistance for aluminum shells and pads.

Transformer Winding Pads: Used where both conductivity and insulation are needed.

Decorative and Signage Industry (Surface Treatment Applications)

Crafts and Signs: Easily anodized into colored, corrosion-resistant decorative pieces or industrial nameplates.

Traffic Signs: High reflectivity and weather resistance for outdoor use.

Stamping and Deep Drawing

Suitable for cookware liners, food can lids, and pharmaceutical aluminum caps.

Bending and Forming

Can be fabricated into complex structures for appliances and industrial containers.

Surface Treatments

Anodizing: Improves wear resistance and aesthetics.

Coating or Painting: Enhances corrosion resistance and decorative effect.

Mechanical Polishing: Increases gloss and smoothness.

Combined processing methods allow 1070 aluminum circles to meet diverse functional and decorative requirements.

Q1: Are 1070 aluminum circles suitable for deep drawing?

A1: Yes. High-purity 1070 aluminum in O or H14 temper is ideal for deep-drawn parts like food cans and cookware liners.

Q2: Can 1070 aluminum circles be used in high-temperature environments?

A2: Suitable for medium to low temperatures (≤150°C), such as baking trays and rice cooker liners; not recommended for high-stress mechanical structures.

Q3: Can 1070 aluminum circles be used in marine environments?

A3: They have some corrosion resistance, but anodizing or surface coating is recommended for prolonged exposure to seawater or salt spray.

Q4: Can thickness and diameter be customized?

A4: Yes. Thickness 0.5-6.0 mm, diameter 50-1200 mm, customizable per customer requirements.

Q5: Are 1070 aluminum circles suitable for electronic heat dissipation?

A5: Yes. High thermal conductivity and good workability make them ideal for heat sinks and LED substrates.

Q6: Are 1070 aluminum circles environmentally friendly?

A6: Yes. 1000 series pure aluminum is non-toxic, harmless, and 100% recyclable, meeting green standards.

Copyright © 2026 By HAOMEI Aluminum CO., LTD. All Rights Reserved. Sitemap