No.14 Waihuan Road, CBD, Zhengzhou, China

No.14 Waihuan Road, CBD, Zhengzhou, China

+86-18703635966

+86-18703635966

No.14 Waihuan Road, CBD, Zhengzhou, China

No.14 Waihuan Road, CBD, Zhengzhou, China

+86-18703635966

+86-18703635966

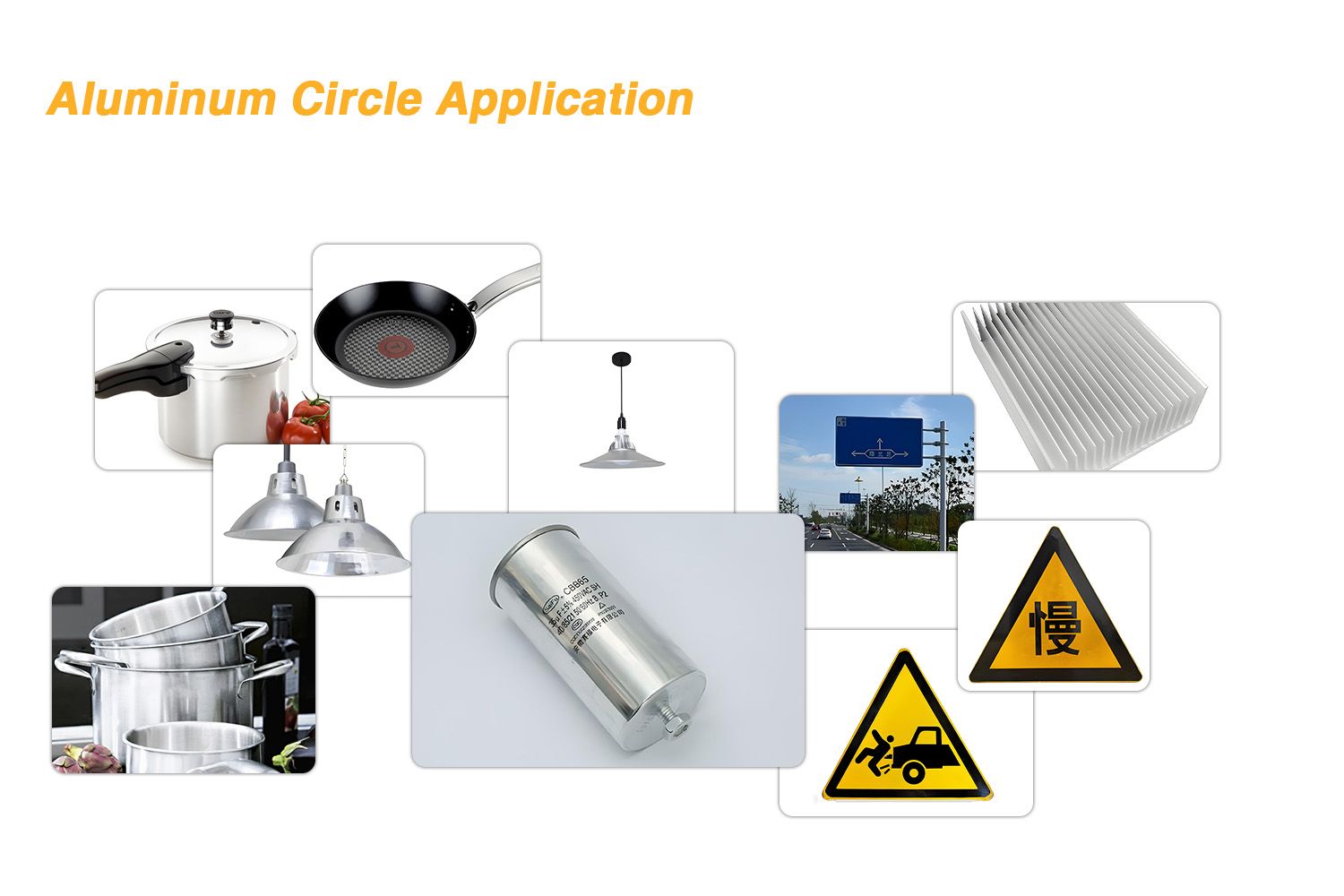

Aluminum discs are ubiquitous in our daily lives, from cookware, lampshades, and traffic signs to precision electronic instruments. HAOMEI Aluminum, as a professional aluminum disc manufacturer, produces 12-inch aluminum circle, 24-inch aluminum circle, 36-inch aluminum circle, cookware aluminum discs, hot-rolled aluminum discs, anodized aluminum discs, and more, providing high-quality aluminum products and OEM customization services.

HAOMEI's 36 inch aluminum circle is a high-quality aluminum alloy substrate designed for large-scale, high-standard projects. It is made from series 1 (pure aluminum), 3 (aluminum-manganese alloy), 5 (aluminum-magnesium alloy), etc., using casting, cold rolling, or cutting processes.

Various alloys are available, tailored to specific applications and performance requirements:

1-series (e.g., 1060, 1100): Over 99% purity, excellent corrosion resistance, electrical and thermal conductivity, easy formability; ideal for deep-drawn components with low strength requirements.

3-series (e.g., 3003): Aluminum-manganese alloy, superior rust resistance, higher strength than 1-series, excellent formability and weldability; widely used general-purpose alloy.

5-series (e.g., 5052, 5083): Aluminum-magnesium alloy, medium-to-high strength, outstanding corrosion resistance in marine environments, good machinability; commonly used in ships, vehicles, etc.

6-series (e.g., 6061, 6063): Aluminum-magnesium-silicon alloy, good formability, weldability, and mechanical strength; can be heat-treated for reinforcement, ideal for structural applications.

8-series (e.g., 8011): Excellent machinability, commonly used for packaging and special applications.

O: Annealed, low hardness, best ductility

H: H14, H18, H32, etc., work-hardened states

Anodized: Forms a hard, stable, porous aluminum oxide layer, improving corrosion and wear resistance. Widely used in cookware, lighting, computer casings, and aerospace components.

Coated: Paint (liquid or powder) is applied and cured on the surface for any color or special effect; aesthetic and long-lasting, suitable for architectural panels, appliances, cookware, lighting, and traffic signs.

Polished: Physical polishing creates a smooth, mirror-like finish with 85%-95% reflectivity, ideal for high-end decor, lighting reflectors, and luxury casings.

| Alloy | 1050, 1060, 1070, 3003, 5052, 5083, 8011, etc. |

| Temper | O/H |

| Diameter | 36 inches |

| Thickness | 0.4mm – 6.0mm |

| Diameter Tolerance | ±0.5mm |

| Thickness Tolerance | ±0.02mm |

| Surface Treatment | Bright, brushed, anodized, mirror polished, color coated, film laminated |

| Packaging | Wooden pallet, wooden crate, custom packaging |

| Samples | 1-3 pieces |

| MOQ | 1-3 tons |

Mechanical Properties

| Alloy | Temper | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) |

| 1050 | O | 60-100 | ≥20 | ≥25 |

| 1100 | H14 | 110-145 | ≥95 | ≥12 |

| 3003 | H32 | 130-180 | ≥115 | ≥10 |

| 5052 | H22 | 210-260 | ≥130 | ≥12 |

| 5754 | H22 | 190-240 | ≥120 | ≥12 |

| 5083 | H111 | 275-350 | ≥125 | ≥12 |

Large size forming capability: 36-inch diameter meets production needs for large equipment and devices.

Excellent machinability: Suitable for deep drawing, spinning, stretching, welding, polishing, and anodizing.

Lightweight design: About 1/3 the weight of steel, reducing transport and handling loads.

Outstanding corrosion resistance: Especially 3-series and 5-series alloys resist moisture and salt spray for long-term durability.

Versatile surface treatments: Mirror polishing, color coating, brushed, anodized, and custom finishes available.

Cookware Manufacturing: Suitable for non-stick pans, pressure cookers, saucepans, and frying pans; excellent thermal conductivity and formability ensure high performance and aesthetics.

Lighting Industry: Ideal for lampshades, lamp shells, and reflectors; lightweight and highly reflective, improving lamp performance and design.

Transportation: Used in automotive, railway, and aerospace components, e.g., fuel caps, wheel covers, reducing weight and improving efficiency.

Construction & Decoration: Roof panels, ceiling decorations, signage; corrosion resistance and easy processing make it ideal for architectural applications.

Mechanical Manufacturing: Used in air tanks, pressure vessels, fan blades, and other precision parts.

HAOMEI Aluminum offers comprehensive customization to meet specific applications:

Precision Cutting: Laser, water jet, or stamping to achieve high-accuracy shapes and dimensions.

Deep Drawing Forming: Excellent for cookware, lampshades, and other deep-formed products.

Surface Treatments: Bright, anodized, brushed, sprayed, polished, etc., enhancing corrosion resistance, appearance, and functionality.

Alloy Selection: Recommendations for strength, corrosion resistance, weldability, and other requirements.

Special Thickness: Non-standard thicknesses available on request.

Aluminum circle discs are packaged according to export standards, wrapped in kraft paper and plastic film, and secured on wooden pallets or crates.

Copyright © 2026 By HAOMEI Aluminum CO., LTD. All Rights Reserved. Sitemap