-

-

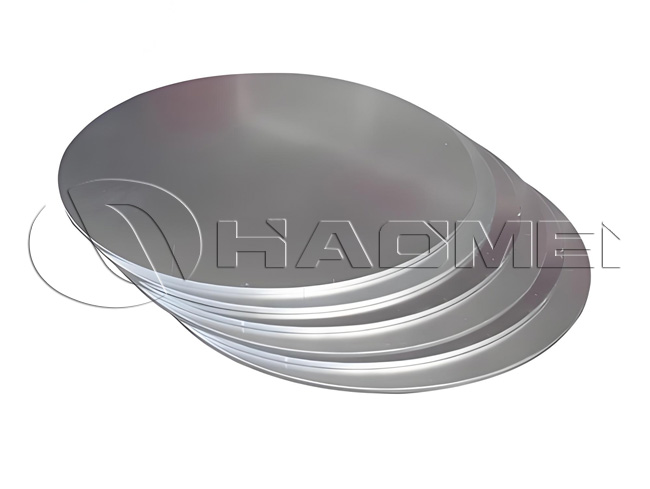

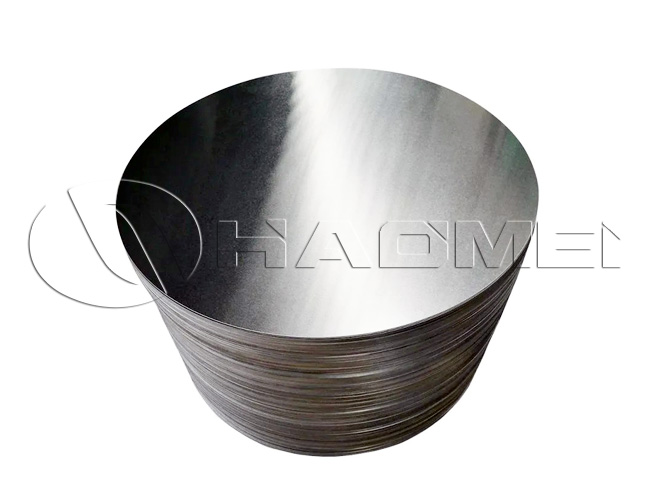

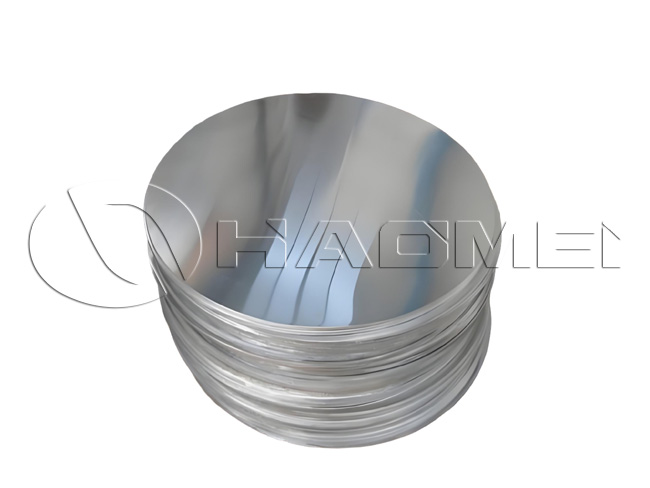

1200 Aluminum Circle

- Alloy 1200

- Temper O, H12/H22, H14/H24, H18, etc.

- Thickness 0.2-3.0mm

- Diameter 20-1000mm

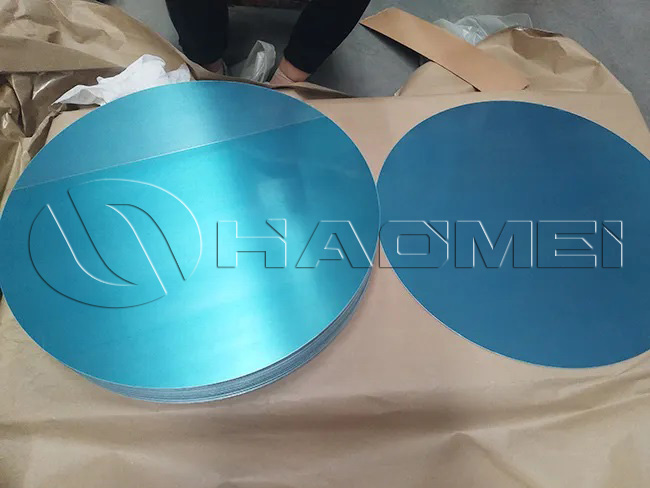

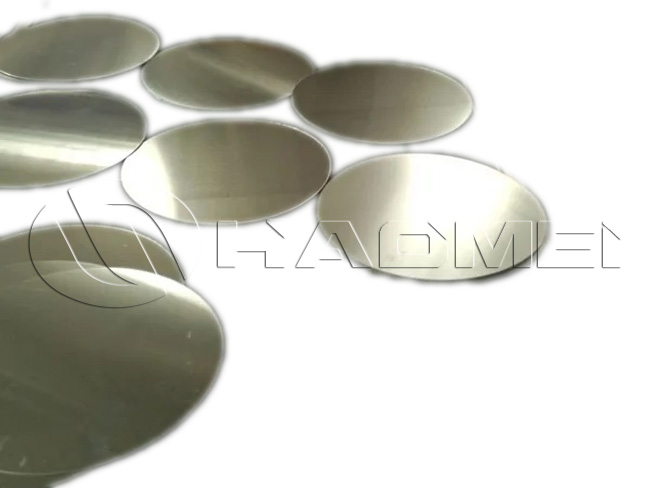

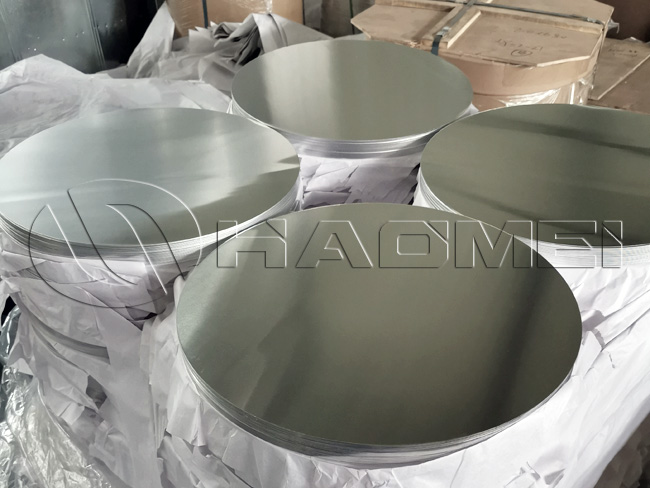

- Surface Mill finish, bright finish

- MOQ 1-3 tons

What is 1200 Aluminum Circle?

1200 aluminum circle is a round sheet material made by stamping, cutting, or spinning processes. 1200 aluminum alloy is one of the alloys with the highest aluminum content in the entire series, with purity reaching above 99.00%. Since it does not contain other alloying elements, the production process is simple, the cost is relatively low, and it is one of the most commonly used series in general industry.

1200 Aluminum Disc Product Information

| Alloy | 1200 |

| Equivalent Designations | A1200, AA1200, 1200A |

| Temper | O, H12/H22, H14/H24, H18, etc. |

| Thickness | 0.2mm - 3.0mm |

| Diameter | 20mm - 1000mm |

| Density | 2.71 kg/m³ |

| Surface | Mill finish, bright finish |

| HS Code | 7606.9100 |

| Samples | Available |

| MOQ | 1-3 tons |

AA1200 Chemical Composition (%)

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Ni | Zn | Ti | Al |

| 1200 | 1.0 | 0.05 | 0.05 | 0.05 | - | - | 0.10 | 0.10 | - | 99.00 |

Mechanical Properties of 1200 Aluminum Circle

| Temper | Tensile Strength (MPa / Ksi) | Elongation (%) |

| O (Soft) | 78 MPa (8-12 Ksi) | 35 (≥2.5 Ksi) |

| H12 (H22) | 95 MPa (11-16 Ksi) | 18 (≥9 Ksi) |

| H14 (H24) | 123 MPa (12-17 Ksi) | 7 (≥9 Ksi) |

| H18 (Full Hard) | 140 MPa (≥16 Ksi) | 4 (≥10 Ksi) |

Key Features of 1200 Aluminum Circle

1. High Purity: Aluminum content not less than 99.00%. It is an industrial pure aluminum with very low impurity content.

2. Excellent Corrosion Resistance: Due to its high purity, it quickly forms a dense oxide film in air, providing strong resistance to atmospheric and mild acid/alkali corrosion.

3. Outstanding Formability: Very soft with excellent ductility (high elongation), highly suitable for deep drawing, stretching, bending, and other cold working processes. It can be easily formed into complex shapes.

4. High Electrical & Thermal Conductivity: The higher the purity, the better the conductivity. 1200 aluminum offers about 59% IACS conductivity, making it an excellent conductor.

5. Low Strength: Being soft, its mechanical strength (such as tensile strength and hardness) is relatively low, unsuitable for load-bearing structural components.

6. Good Machinability & Weldability: Cutting machinability is average (due to softness and tool sticking), but welding performance is excellent.

7. Excellent Surface Treatment Performance: Well-suited for anodizing, painting, electroplating, etc. After anodizing, it can achieve a beautiful and durable finish.

Production Process

The production of 1200 aluminum circles generally uses two main processes:

Continuous Casting: Melting aluminum ingots and casting directly into sheets, then rolling into discs. Circles made by this process are usually used for spinning.

Cold Rolling: Aluminum coils are processed through cold rolling mills and then punched into discs. Circles from this process are more suitable for deep drawing and stamping.

Applications

Cookware Manufacturing: The most common use of 1200 aluminum circles. They are used to produce frying pans, pressure cookers, pizza pans, kettles, rice cooker liners, etc.

Lighting Manufacturing: With good reflectivity and formability, they are widely used in streetlights, spotlights, lampshades, and reflectors.

Traffic Signs: Suitable for producing various circular road signs.

Others: Automotive parts, building decorative components, etc.

Pricing & Minimum Order

The price of aluminum discs per kilogram is around 1200 (subject to change).

Your minimum order quantity (MOQ) is 500 kg per specification.

Please note that the aluminum circle price fluctuates daily depending on aluminum ingot prices, shipping costs, and processing fees. Thickness, alloy grade, and surface treatment also affect the final price.

Contact our sales manager now to get the latest quotation!

More Aluminum Circle Products

| Series | Temper | Alloy | Features | End Use |

| 1xxx | O, H2, H4, H*6, H18, H111, H112 | 1050, 1060, 1070, 1100, 1200 | 1. Aluminum content >99%, excellent formability 2. High reflectivity 3. Stable anodizing surface 4. Low cost | 1. General cookware: polishing, sandblasting, pressed lids, aluminum pots 2. Lighting parts: downlights, panel lights, streetlight reflectors 3. Signs & construction: traffic signs, curtain walls, ceilings |

| 3xxx/4xxx | 3003, 3004, 3005, 3105, 4006 | 1. Excellent formability 2. High elongation, suitable for deep drawing 3. Fine grain, smooth surface, high reflectivity | 1. Premium cookware: anodizing, enamel coating, spraying, deep drawing; non-stick pans, pressure cookers 2. Lighting parts 3. Signs & construction | |

| 5xxx | 5052, 5754, 5083 | 1. Low density, lightweight 2. High tensile strength, elongation, and fatigue strength 3. Higher grain grade, better surface finish | 1. Premium cookware: anodizing, enamel coating, spraying, deep drawing; non-stick pans, pressure cookers 2. Pressure vessels: high-pressure cookers | |

| 8xxx | 8011 | 1. Excellent anodizing effect 2. Stable performance, high surface quality | Premium cookware: pearl-anodized cookware |

No.14 Waihuan Road, CBD, Zhengzhou, China

No.14 Waihuan Road, CBD, Zhengzhou, China +86-18703635966

+86-18703635966

+86-18703635966

+86-18703635966

sales@alummc.com

sales@alummc.com

8618703635966

8618703635966