No.14 Waihuan Road, CBD, Zhengzhou, China

No.14 Waihuan Road, CBD, Zhengzhou, China

+86-18703635966

+86-18703635966

No.14 Waihuan Road, CBD, Zhengzhou, China

No.14 Waihuan Road, CBD, Zhengzhou, China

+86-18703635966

+86-18703635966

Aluminum circles (also called aluminum discs) are widely used as semi-finished blanks for deep drawing, spinning, stamping, and CNC turning. Typical downstream products include cookware bodies, pressure cooker parts, lamp reflectors, traffic signs, nameplates, and various formed housings. In production, the alloy choice directly affects forming stability, surface finish, corrosion resistance, and cost.

As a manufacturer of aluminum circles, we are often asked to explain the practical difference between 3003 and 1050 aluminum circles. Both are common choices, but they are designed for different performance priorities. This article compares 3003 vs 1050 aluminum discs from material characteristics through manufacturing control points, so engineering teams can specify the correct alloy for their forming and finishing processes.

1050 belongs to the 1xxx series, with very high aluminum content. It is selected when users prioritize high electrical/thermal conductivity, excellent corrosion resistance in many environments, and consistent anodizing response for decorative surfaces. Because it is relatively soft, 1050 aluminum circle is also easy to form for moderate drawing and spinning, particularly in fully annealed conditions.

Key characteristics of 1050 aluminum disc:

Very high purity, good conductivity

Very good corrosion resistance

Very good anodizing appearance consistency (typically)

Lower strength than 3xxx alloys

3003 belongs to the 3xxx series, where manganese is the main alloying element. The Mn addition increases strength and improves work hardening behavior compared with 1050, which often translates into better resistance to deformation during forming and improved dent resistance in service. 3003 aluminum circles are widely used for cookware and general deep drawing due to their stable forming window and good corrosion resistance.

Key characteristics of 3003 aluminum disc:

Higher strength than 1050 with good formability

Good corrosion resistance

Stable deep drawing and spinning performance

Anodizing possible, but color uniformity depends more on process control than with 1050

For buyers evaluating other 3xxx grades for specific forming windows, our 3000 Series Aluminum circle range covers multiple options for different draw depths and stiffness requirements.

The table below summarizes typical parameters used in aluminum circle procurement. Exact values depend on temper, thickness, and process route. For design and quotation, we confirm the target application (deep drawing, spinning, anodizing, cookware, signage) and recommend the most suitable coil source and heat treatment.

| Item | 1050 Aluminum Circle | 3003 Aluminum Circle |

|---|---|---|

| Alloy series | 1xxx (commercially pure) | 3xxx (Al-Mn) |

| Main alloying element | Al (high purity) | Mn (typ. around 1%) |

| Typical tempers for circles | O, H12, H14, H16 | O, H12, H14 |

| Relative strength | Lower | Higher |

| Forming behavior | Very ductile; best for light to moderate draws and spinning | Excellent for deep drawing and spinning; better resistance to thinning and distortion |

| Work hardening | Lower | More pronounced and controllable |

| Surface finish potential | Very smooth; excellent for decorative finishing | Smooth; excellent for cookware and industrial surfaces |

| Anodizing response | Generally very uniform appearance | Anodizing feasible; uniformity depends more on surface prep and process |

| Corrosion resistance | Excellent | Very good |

| Thermal conductivity | Higher | Lower than 1050 |

| Typical diameter range (factory supply) | Commonly 80 mm to 1200 mm (customizable) | Commonly 80 mm to 1200 mm (customizable) |

| Typical thickness range (factory supply) | Commonly 0.4 mm to 6.0 mm (customizable) | Commonly 0.5 mm to 6.0 mm (customizable) |

| Typical end uses | reflectors, signage, anodized parts, caps | cookware bodies, drawn containers, housings |

If the process includes multi-step deep drawing with higher draw ratios, 3003 aluminum circles are often the safer selection. The alloy provides a better strength-ductility balance, and its work hardening behavior helps maintain shape and reduce wrinkling sensitivity when tooling and lubrication are well controlled.

1050 aluminum discs can also be deep drawn, especially in O temper, but their lower strength can increase the chance of local thinning, orange peel risk if process conditions are not optimized, or deformation during subsequent handling. For shallow to medium draws, 1050 remains a cost-effective and reliable option.

Both 3003 and 1050 are widely used as aluminum circle for spinning. In general:

1050 can provide very smooth spun surfaces and is easy to flow.

3003 provides better stiffness and dent resistance after forming, which may benefit cookware and functional housings.

For stamped parts and blanks, edge quality and flatness are strongly affected by:

base coil quality and cleanliness

slitting stability

blanking die clearance

burr control and post-processing

As a manufacturer, we control burr height and edge integrity by matching tooling and lubrication to thickness and temper. When required, we supply deburred circles and strictly monitor edge cracks for deep drawing grades.

If the product is primarily decorative and anodized (for example, lamp components, signage plates, cosmetic covers), 1050 aluminum circle is frequently specified because high-purity aluminum typically produces a more uniform anodized look.

3003 aluminum circles can also be anodized, but alloying elements can influence color uniformity and reflectivity. In practice, we focus on:

consistent coil source and chemistry range

controlled annealing to stabilize grain structure

surface cleanliness and rolling oil management

stable brushing or polishing parameters before anodizing

For cookware aluminum circle, 3003 is widely used due to forming stability. Both 1050 and 3003 can be used under PTFE and ceramic coatings, but surface preparation and roughness control are critical. We can supply circles suitable for:

non-stick coating lines

hard anodizing lines

brushed or bright finish requirements

As a factory, our process is engineered to deliver consistent forming performance and tight dimensional control. Our standard production route includes:

Raw material selection (coil/plate)

verified chemistry and mechanical property windows

suitability check for deep drawing or spinning

Slitting and circle blanking

controlled slitting to maintain edge quality

high precision punching/blanking for diameter consistency

Heat treatment and temper control

O temper annealing for deep drawing and spinning

H tempers for applications requiring higher rigidity

Surface and edge management

rolling oil control, surface inspection, and cleaning options

burr height control, optional edge deburring

Packing and logistics

anti-scratch interleaving when required

moisture protection and seaworthy packing for export

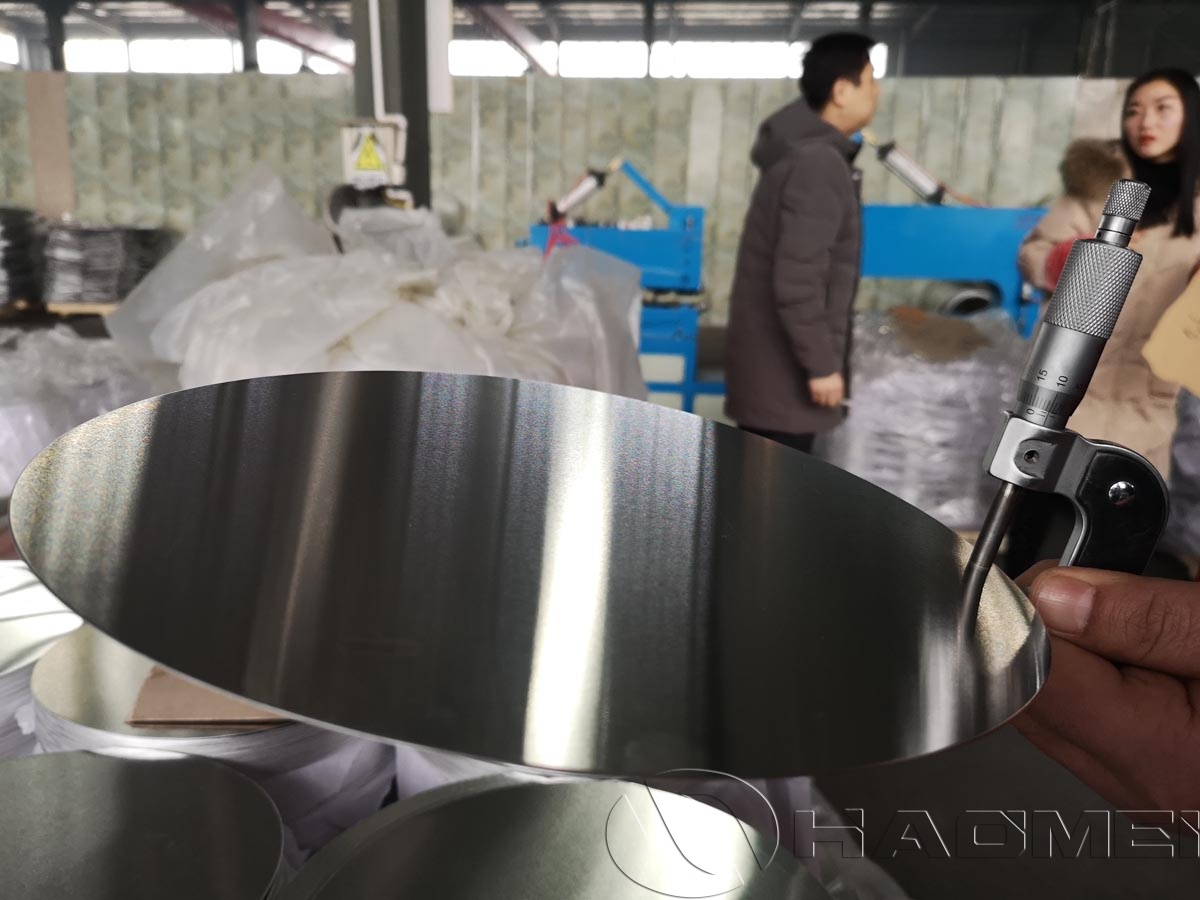

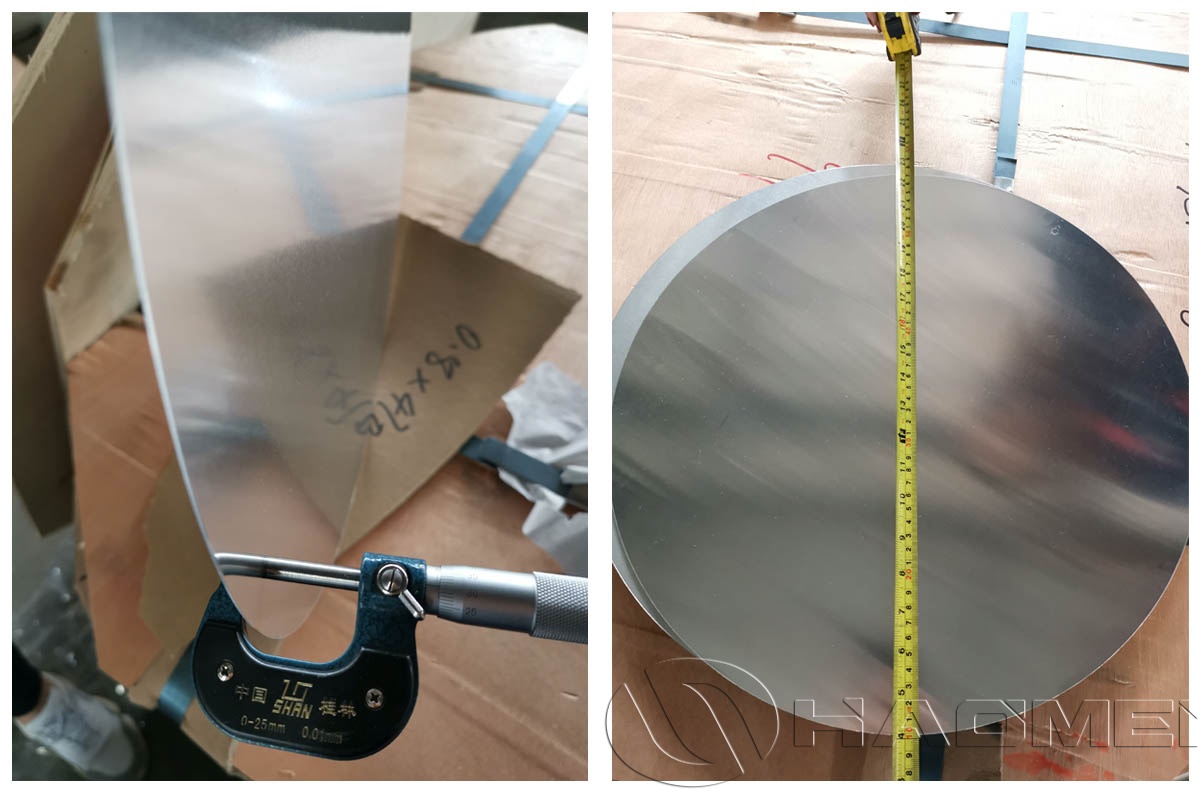

To support stable downstream forming, our QC focuses on parameters that directly influence scrap rate and surface yield:

Chemical composition verification: heat number traceability and incoming inspection

Thickness tolerance and gauge mapping: ensures even deformation during drawing

Diameter tolerance and roundness: improves die centering and reduces eccentric thinning

Flatness control: critical for automatic feeding and consistent forming

Surface inspection: scratches, inclusions, oil stains, and roll marks

Grain structure control: optimized annealing to reduce earing tendency

We can supply material in accordance with common international expectations for aluminum sheet and circles, and we align documentation to customer requirements, including inspection reports, packing lists, and batch traceability.

Different factories use different dies, lubricants, and draw sequences. To supply the correct 1050 or 3003 aluminum circle, we normally confirm:

Application: cookware, lamp reflector, sign, electrical part, drawn container

Forming method: stamping, deep drawing, spinning

Temper: O for deep drawing, H12/H14 for higher rigidity requirements

Thickness and diameter: including tolerance targets

Surface requirement: mill finish, bright finish, brushed, anodizing-grade, coating-grade

Edge requirement: standard blanked edge or deburred

Packing requirement: pallet type, interleaving, maximum bundle weight

This approach reduces trial-and-error and supports stable mass production at the customer site.

lamp reflectors and lighting parts requiring high reflectivity and anodizing uniformity

traffic signs and nameplates where corrosion resistance and appearance are important

electrical and thermal components benefiting from higher conductivity

general spinning parts with moderate strength requirements

cookware bodies, pots, pans, and pressure cooker components

deep drawn containers and housings for appliances

stamped covers where improved dent resistance is preferred

industrial parts requiring a stronger, more stable forming alloy than 1xxx series

The difference between 3003 and 1050 aluminum circles comes down to the performance priority. If the product needs higher strength, stable deep drawing behavior, and better dent resistance in service, 3003 aluminum circles are typically the preferred choice. If the priority is high purity, conductivity, and consistent decorative anodizing appearance, 1050 aluminum circles are often more suitable.

As a manufacturer, we support long-term programs with stable coil sourcing, controlled temper production, and batch traceability. Our technical team can review your forming route, tooling conditions, and surface requirements, then recommend the alloy, temper, and tolerances that reduce scrap and improve production stability. We welcome cooperation based on consistent quality, predictable lead times, and engineering-oriented support for ongoing projects.

Copyright © 2026 By HAOMEI Aluminum CO., LTD. All Rights Reserved. Sitemap