-

-

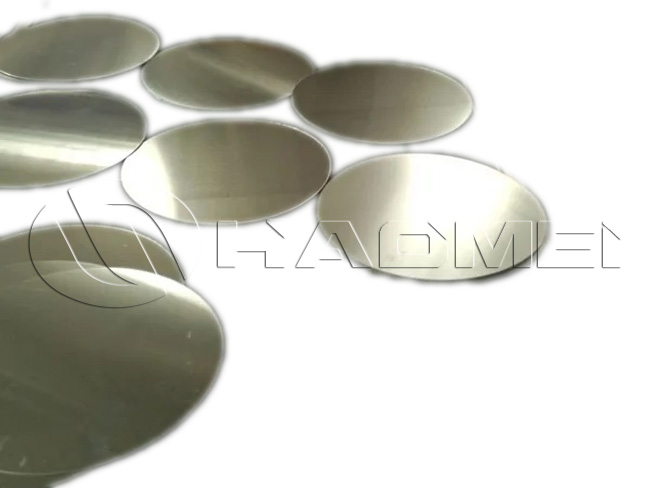

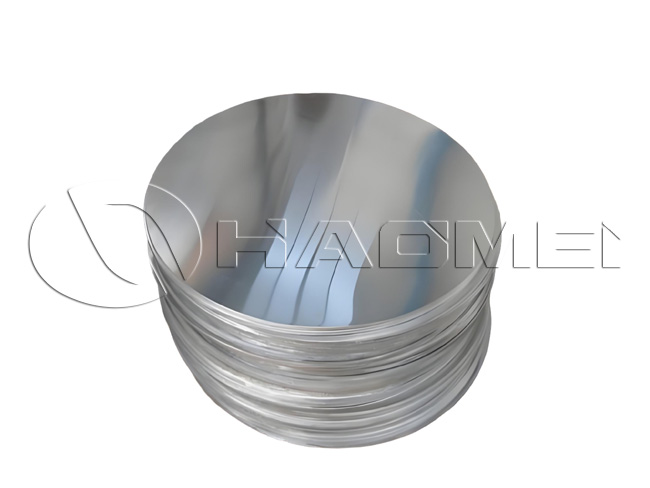

3105 Aluminum Circle

- Alloy 3105

- Tempers H14, H16, H18, H22, etc.

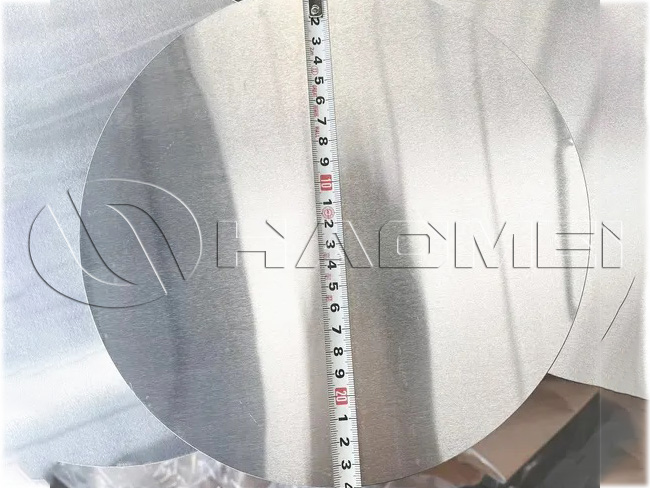

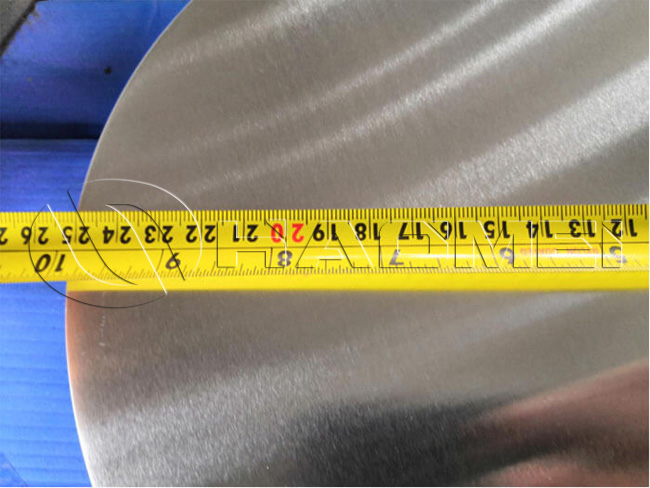

- Diameter 20-1000mm

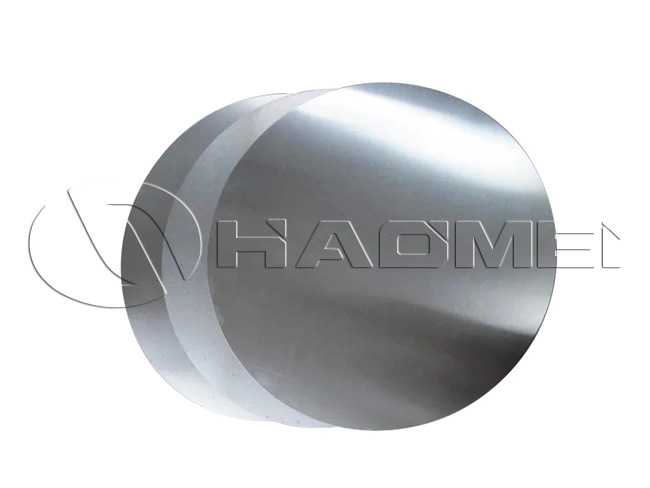

- Thickness 0.15-0.5mm

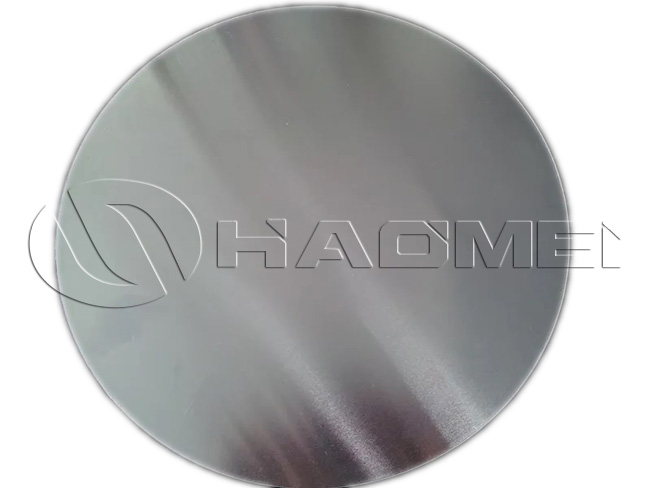

- Surface Finishes Mill finish, brushed, coated, printed, anodized

- Colors Silver, gold, or custom colors

- MOQ 1-3 tons

About HAOMEI Aluminum

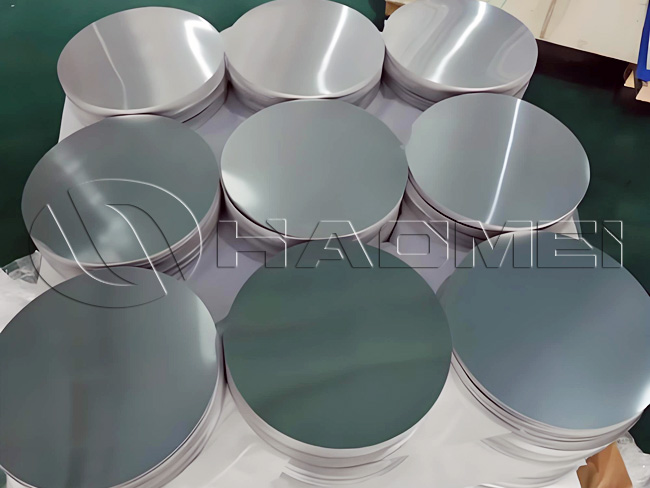

As a professional aluminum circle manufacturer, HAOMEI Aluminum supplies products widely used in cookware, automotive, electronics, and construction industries. We provide heavy-gauge circles up to 5 mm thick and 1200 mm in diameter, fully meeting diverse production needs.

What is 3105 Aluminum Circle?

3105 aluminum belongs to the 3000-series aluminum alloys, mainly composed of aluminum, manganese, and magnesium. This alloy cannot be hardened by heat treatment but features excellent weldability, formability, and corrosion resistance.

Production Process

3105 aluminum circles are produced either by CC (continuous casting) or DC (direct cold rolling) methods.

They are typically processed through automatic decoiling and blanking lines, achieving material utilization rates above 80%. Standard production supports circle diameters of 85-700 mm, suitable for large-scale manufacturing.

Common Tempers of 3105 Aluminum Circle

O (Annealed): Soft condition, excellent ductility, best for deep drawing and complex forming.

H12: Low strength but good formability, suitable for moderate stamping.

H14: Balanced strength and ductility, commonly used for general bottle caps.

H16: Higher strength, suitable for stiffer caps requiring rigidity.

H18: Maximum strength and pressure resistance, ideal for carbonated beverage caps.

H22/H24: Partially annealed, providing a balance of strength, ductility, and processing performance.

Key Features of 3105 Aluminum Circles

1. Excellent Corrosion Resistance: Performs well in air, water, and oil environments, ideal for long-term exposure to humid or corrosive conditions.

2. Medium Strength: Falls between pure aluminum and high-strength alloys, with toughness suitable for stamping and deep drawing.

3. Good Formability & Weldability: Easy to cold work into complex shapes, with strong TIG/MIG welding compatibility.

4. Aesthetic Surface: Smooth and bright appearance, suitable for anodizing, painting, or decorative finishes.

5. Good Thermal Conductivity: Efficient heat transfer, making it ideal for cookware and heating applications.

Product Information

| Alloy | 3105 |

| Temper | H14, H16, H18, H22, etc. |

| Diameter Range | 20 mm - 100 mm (customizable) |

| Thickness Range | 0.15 mm - 0.50 mm |

| Surface Finishes | Mill finish, brushed, coated, printed, anodized |

| Colors | Silver, gold, or custom colors |

| Samples | Available |

| MOQ | 1-3 tons |

Chemical Composition of 3105 Aluminum (%)

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Other | Al |

| 3105 | 0.6 | 0.7 | 0.3 | 0.30-0.80 | 0.20-0.80 | 0.2 | 0.4 | 0.1 | 0.15 | Remainder |

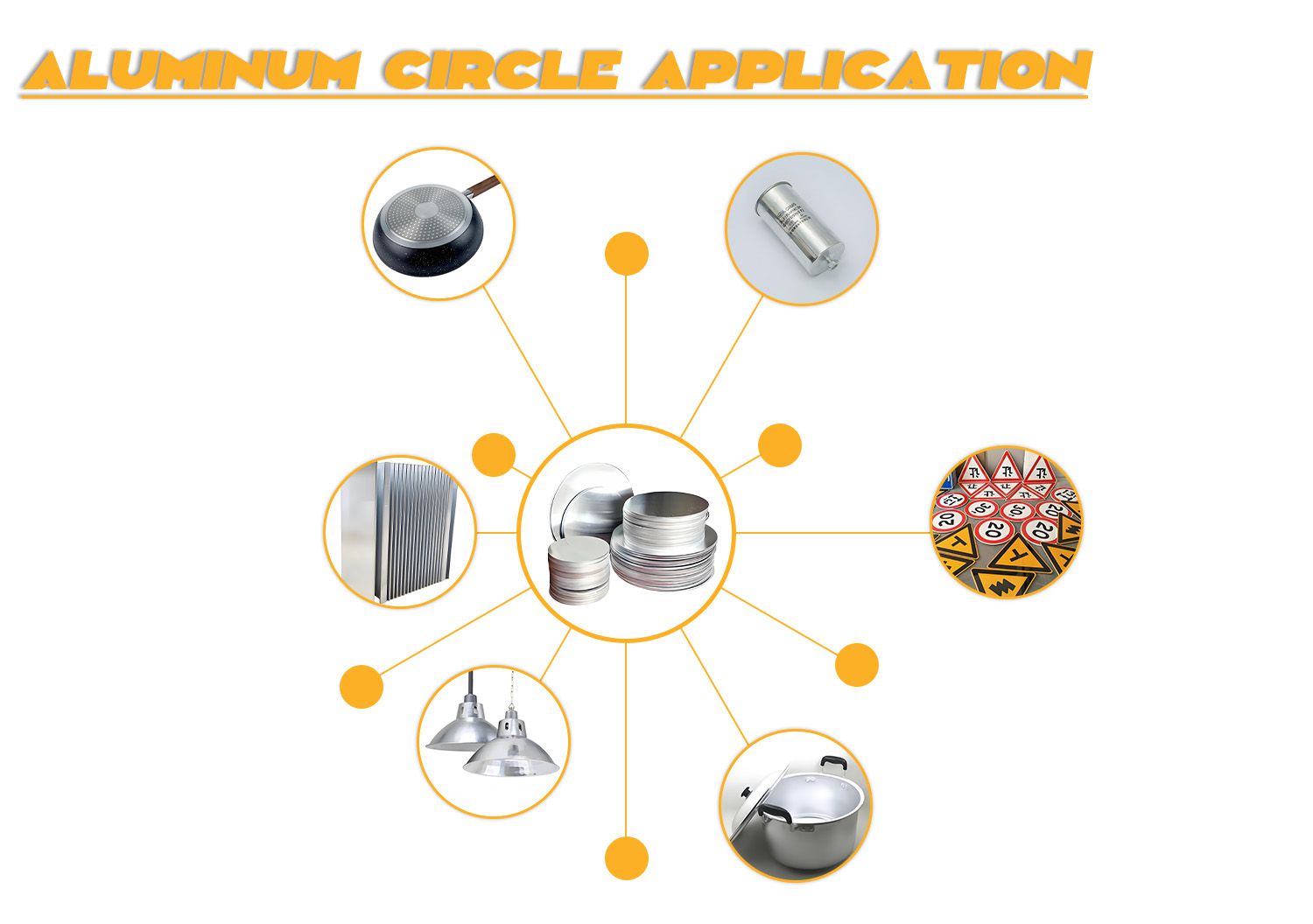

Applications of 3105 Aluminum Circles

Cookware & Containers: Pot lids (non-stick, pressure cooker lids), rice cooker liners, and various cans, thanks to deep drawing ability and food safety.

Lighting & Hardware: Lampshades, water heater casings, and other hardware components.

Bottle Caps & Packaging: Widely used in beverage caps, cosmetic lids, and other packaging containers due to corrosion resistance and easy formability.

Building Decoration: Partitions, panels, and ceilings, valued for both weather resistance and appearance.

Comparison with Other Aluminum Circles

3105 vs. 1050/1060 (Pure Aluminum Series):

Strength: 3105 is stronger and can withstand higher loads.

Corrosion Resistance: Both are good, but 3105 offers better rust resistance in some environments.

Applications: 1050/1060 excels in conductivity and is used in electronics and radiators, while 3105 is better for cookware, building materials, and traffic signs.

3105 vs. 3003 (Al-Mn Alloy Series):

Composition: Both are Al-Mn alloys; 3105 contains trace silicon and iron, giving it slightly higher strength.

Formability: 3105 is slightly stronger, but formability is similar; they can often be interchanged.

Applications: 3003 is widely used in kitchenware, pressure vessels, and chemical tanks, while 3105 is preferred where higher strength is required without losing formability.

3105 vs. 5052 (Al-Mg Alloy Series):

Strength: 5052 is much stronger, a medium-high strength alloy.

Corrosion Resistance: 5052 performs exceptionally well, especially in marine environments.

Cost & Processing: 5052 is more expensive and harder to process than 3105.

Applications: 5052 is used for fuel tanks, ship components, and lamp brackets requiring higher strength, while 3105 is more cost-effective for medium-strength, rust-resistant applications.

How to Choose the Right 3105 Aluminum Circle

Define Application Requirements: Consider product needs for strength, formability (deep drawing, stretching), corrosion resistance, and weldability.

Select Temper Carefully: For deep drawing, choose O temper; for balanced strength and formability, select H2x or H3x tempers.

Check Dimensions: Ensure thickness and diameter match your design specifications.

Choose a Reliable Manufacturer: Look for suppliers with international certifications (ISO9001, CE, SGS, etc.).

Inspect Surface Quality: High-quality circles should have clean, flat surfaces, free of scratches, pinholes, oil stains, oxidation, and burrs on the edges.

No.14 Waihuan Road, CBD, Zhengzhou, China

No.14 Waihuan Road, CBD, Zhengzhou, China +86-18703635966

+86-18703635966

+86-18703635966

+86-18703635966

sales@alummc.com

sales@alummc.com

8618703635966

8618703635966