-

-

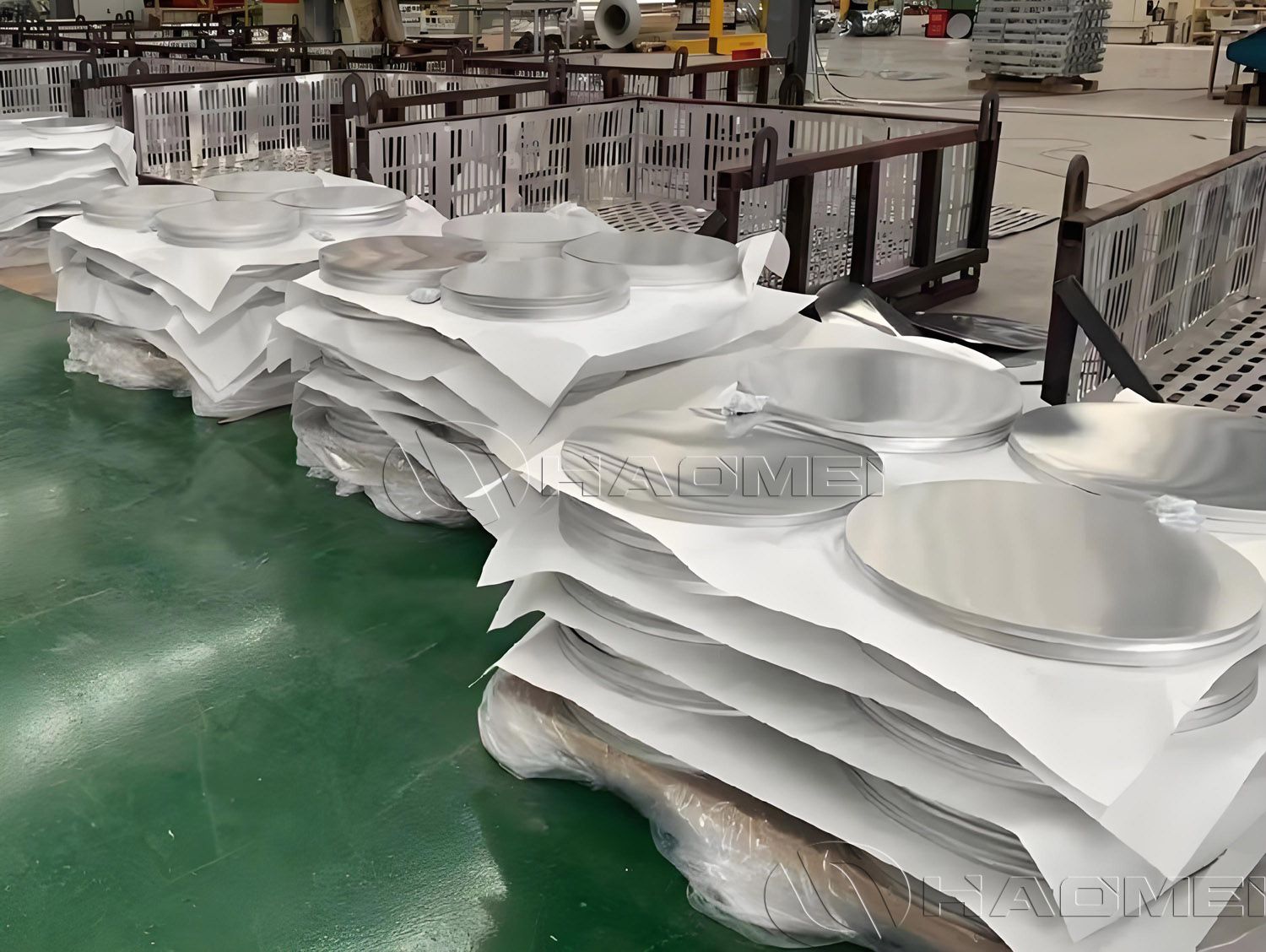

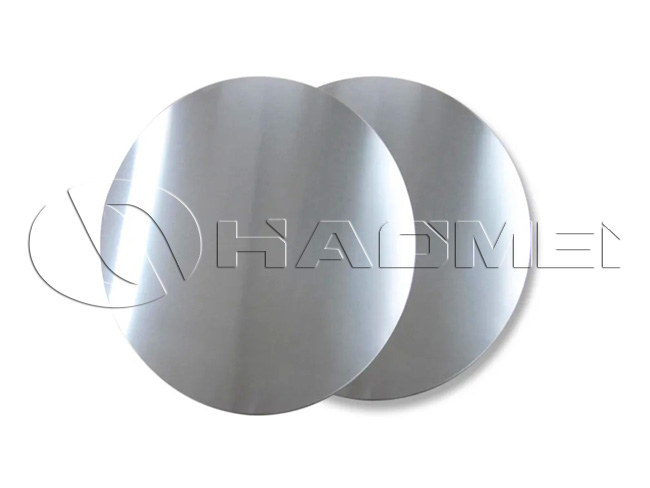

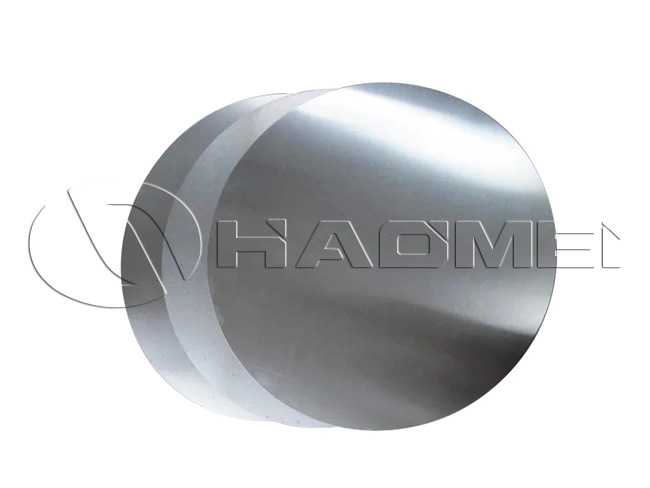

1100 Aluminum Circle

- Alloy 1100

- Thickness 0.2-0.6mm

- Diameter 20-1500mm

- Temper O, H12, H14, H18, etc.

- MOQ 1-3 tons

HAOMEI Aluminum produces 1100 aluminum circle discs in a wide range of thicknesses and diameters. Thickness options include 0.5mm, 0.6mm, 0.7mm, up to 3.0mm. Made from 99% pure aluminum, our discs are widely used in the manufacture of cookware, lampshades, traffic signs, and more.

We supply aluminum circles in 1100 alloy, including 1100 O, 1100 H12, 1100 H14, and 1100 H18 temper options for customers to choose from.

1100 Aluminum Circle Product Information

| Alloy | 1100 |

| Equivalent Designations | AA1100, A1100, 1100A, Al99.00 |

| Thickness | 0.2mm - 6.0mm |

| Diameter | 20mm - 1500mm |

| Thickness Tolerance | ±0.02mm |

| Diameter Tolerance | ±1mm |

| Temper | O, H12, H14, H18, etc. |

| Hardness | 20HB - 35HB |

| Standards | GB/T 3880-2012, ASTM B209 |

| MOQ | 1-3 tons |

Chemical Composition (%)

| Alloy | Si+Fe | Cu | Mn | Mg | Cr | Ni | Zn | Ti | Zr | Al |

| 1100 | ≤0.95 | 0.05-0.20 | 0.05 | - | - | - | 0.10 | - | - | 99.0 |

Mechanical Properties

| Property | O | H12 | Half-hard (H14) | Full-hard (H18) |

| Tensile Strength (MPa) | 60-95 | 85-110 | 95-125 | ≥125 |

| Yield Strength (MPa) | 25-45 | 55-75 | 75-95 | ≥95 |

| Elongation (%) | ≥25 | 15-20 | 8-12 | ≥3 |

| Hardness (HB) | 18-25 | 22-28 | 28-35 | ≥35 |

Features of 1100 Aluminum Circle

Excellent Corrosion Resistance: Among all aluminum alloys, pure aluminum has the best corrosion resistance. 1100 aluminum naturally forms a dense oxide film in air, effectively resisting corrosion from atmosphere, water, and many chemicals.

Good Workability: Outstanding plasticity (elongation ≥25% in annealed condition), excellent deep drawing, spinning, and welding (gas welding/TIG welding) properties, suitable for complex forming.

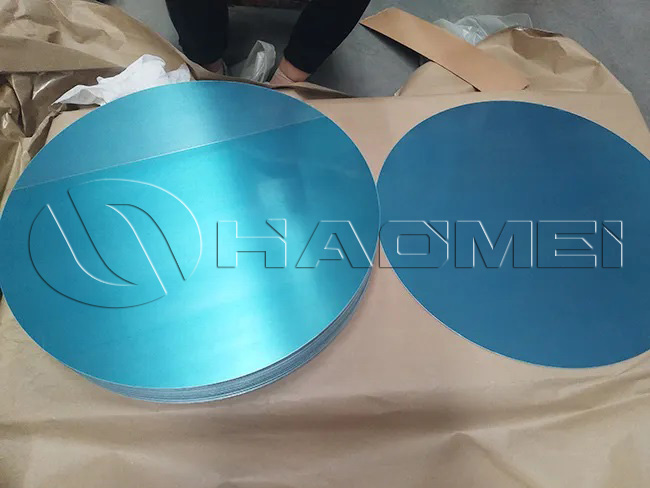

Surface Treatment Advantage: After anodizing, corrosion resistance is enhanced, and both high-gloss and matte finishes can be achieved, offering excellent aesthetics.

Good Electrical & Thermal Conductivity: 1100 aluminum provides excellent electrical and thermal conductivity, second only to higher-purity grades like 1050 and 1060. This makes it ideal for applications requiring heat dissipation or conductivity.

Non-heat-treatable Alloy: 1100 cannot be strengthened by heat treatment; strength is mainly improved by cold working (such as cold rolling).

Applications of 1100 Aluminum Circle

Cookware Manufacturing: Used in pressure cookers, soup pots, non-stick pans, frying pans, and other cookware bases and bodies. Its good thermal conductivity ensures even heat distribution.

Lighting Industry: For reflectors, lampshades, and decorative components.

Chemical & Food Industry: Used to produce storage containers, packaging materials, and various utensils due to its non-toxic and corrosion-resistant nature.

Traffic Signs: Commonly used for road signboards thanks to its formability and weather resistance.

Others: Radiators, stamping parts, and other applications where high strength is not critical.

1100 vs. 1060 vs. 1050

Comparison: Aluminum Circle 1100 vs. 1060

Both 1100 and 1060 belong to the pure aluminum series with good ductility and formability, but there are differences:

1060 aluminum has higher aluminum content (≥99.6%), lower strength, and excellent ductility, making it more suitable for deep drawing and spinning.

1100 aluminum contains a small amount of copper, offering better strength and corrosion resistance than 1060, with improved welding performance and surface treatment results. It is often used in applications requiring higher appearance and corrosion resistance.

Comparison: Aluminum Circle 1100 vs. 1050

Both 1100 and 1050 belong to the pure aluminum series with excellent ductility and workability. Differences lie in composition and properties:

1050 aluminum has higher aluminum content (≥99.5%), higher purity, and better plasticity, making it more suitable for processes requiring excellent formability such as deep drawing and spinning.

1100 aluminum contains a small amount of copper, which improves strength, corrosion resistance, and surface finishing while maintaining good ductility, making it suitable for applications requiring both mechanical performance and appearance.

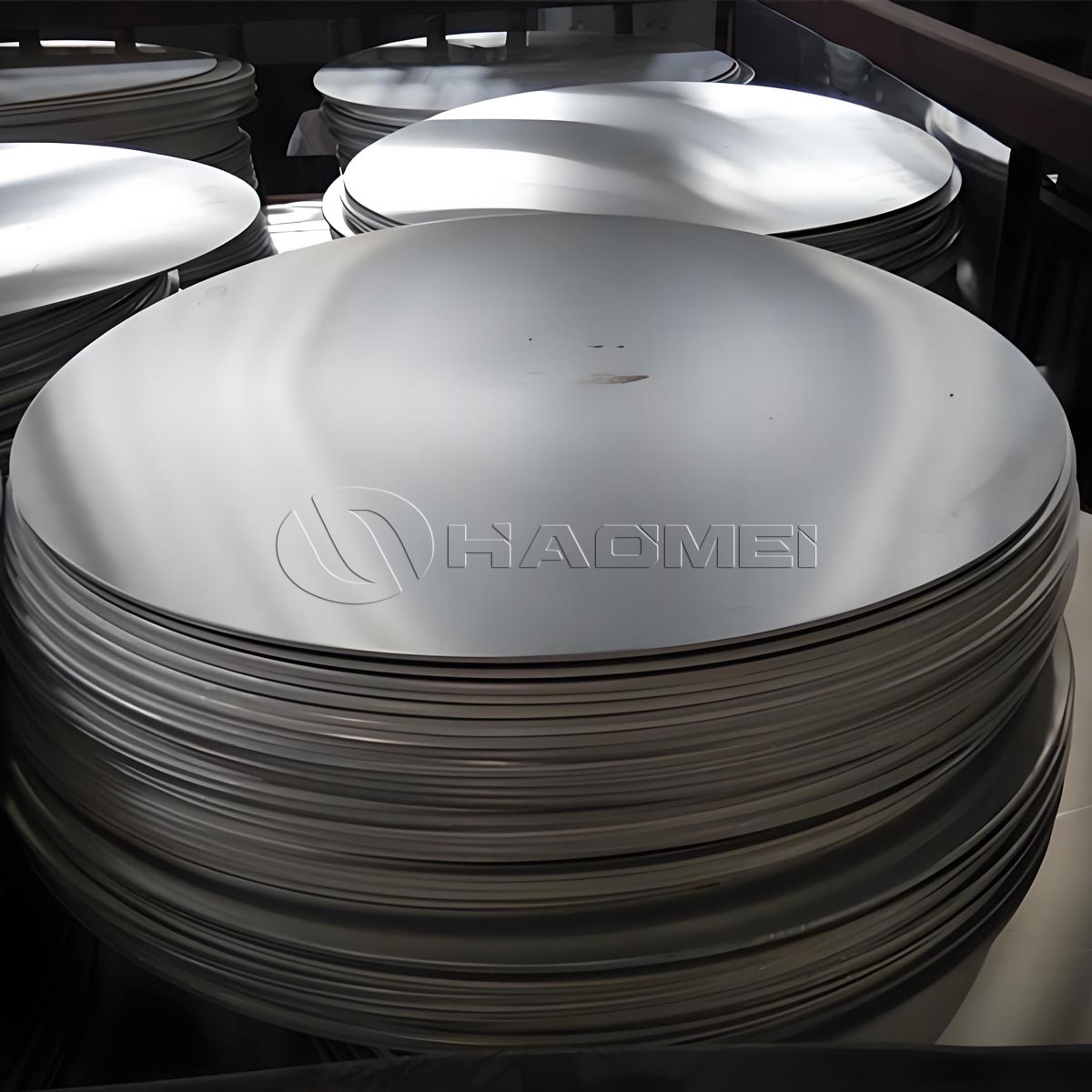

Packaging & Transportation

Packaging: Vacuum moisture-proof packaging + wooden pallet, with alloy designation and standard clearly marked on the outer carton.

Transportation: By sea/land; avoid humid environments; stacking height ≤1.5m.

No.14 Waihuan Road, CBD, Zhengzhou, China

No.14 Waihuan Road, CBD, Zhengzhou, China +86-18703635966

+86-18703635966

+86-18703635966

+86-18703635966

sales@alummc.com

sales@alummc.com

8618703635966

8618703635966