-

-

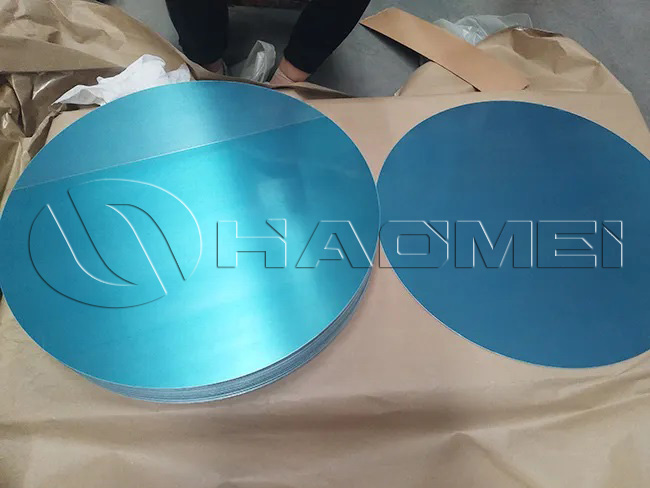

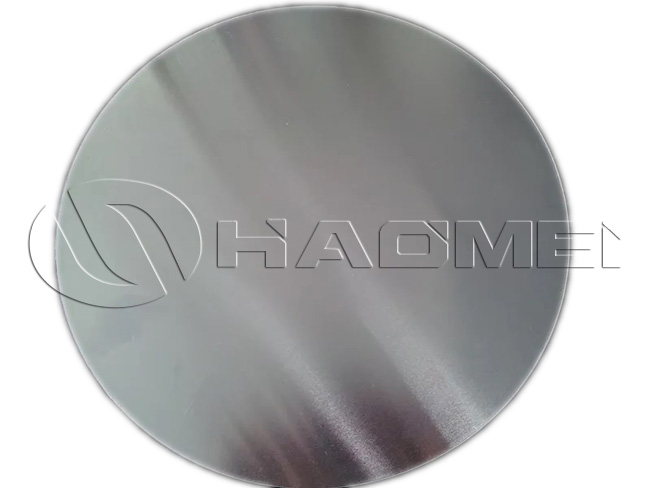

3004 Alminum Circle Disc

- Alloy 3004

- Tempers O, H12, H14, H16, H18, H22, H24, H26, H28

- Thickness 0.4-3.0 mm

- Diameter 100-1500 mm

- Surface Treatment Anodized, coated, brushed, etc.

- Application Cookware, lampshades, architectural decorations, heat sinks, etc.

- MOQ 1-3 tons

What is 3004 Aluminum Circle?

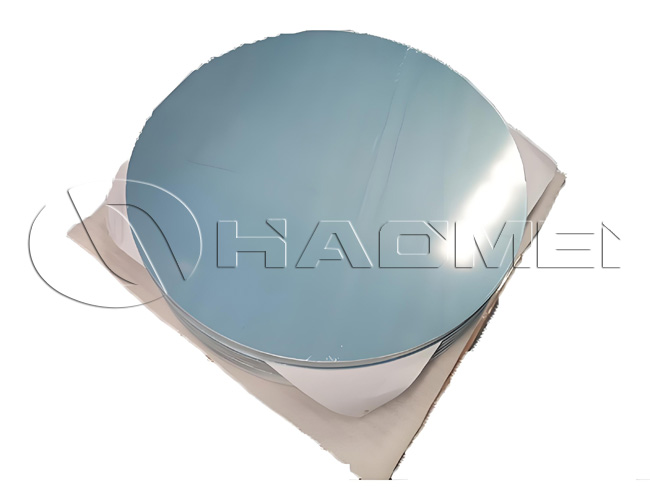

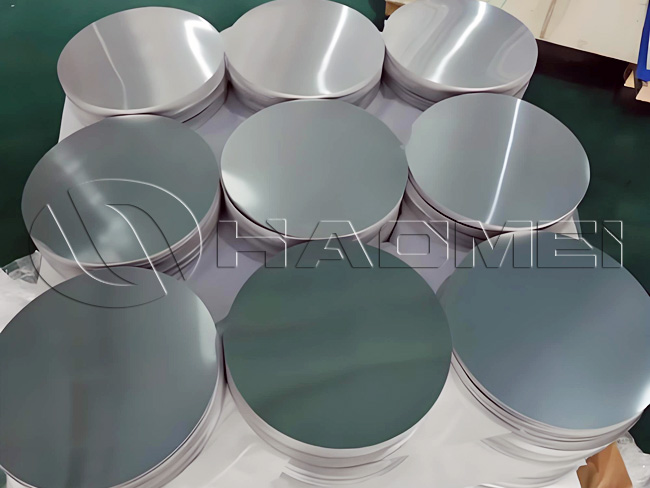

3004 aluminum circle is a round sheet material made from 3004 aluminum alloy. It belongs to the aluminum-manganese alloy series (mainly containing manganese), with higher strength than 3003 aluminum alloy while maintaining excellent plasticity. It is well-suited for deep drawing processing, has outstanding corrosion resistance-especially in humid and chemical environments-offers good weldability, and can be produced by cold rolling or hot rolling processes.

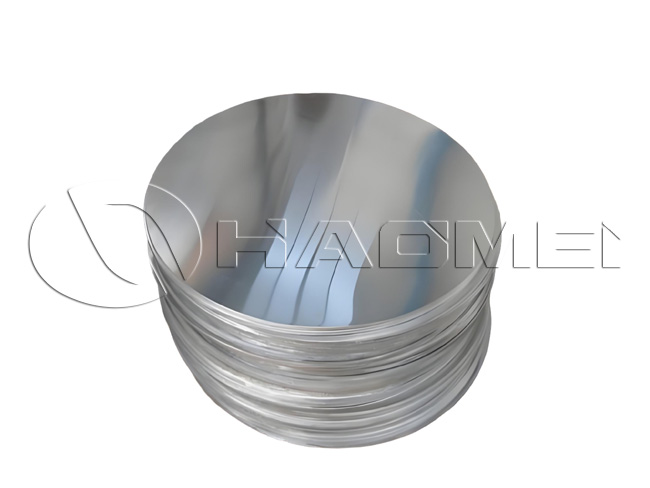

Processed through stamping, cold rolling, and fully automatic production lines (including decoiling, leveling, and punching), 3004 aluminum circle discs feature high efficiency (40-55 pieces per minute) and high material utilization (over 80%).

MC Aluminum supplies 3004 circles in common tempers including O (annealed), H12, H14, H16, H18, H19, H22, H24, H26, and H28. Surface treatments such as anodizing, polishing, or brushing can be applied to enhance corrosion resistance.

3004 aluminum circles are widely used in cookware deep drawing, lighting reflectors, traffic signs, capacitor shells, and other industrial manufacturing applications.

Key Features of 3004 Aluminum Circle

Excellent Corrosion Resistance: The addition of manganese and magnesium elements provides outstanding resistance, especially in humid or salt-spray environments.

Good Formability: With excellent ductility and plasticity, it can be easily deep drawn or stretched, suitable for producing complex shapes.

Moderate Strength: While not as strong as some high-strength alloys, it is stronger than pure aluminum, sufficient for most daily-use applications.

Good Weldability: Can be easily joined by welding, which is important for containers and similar applications.

Product Information

| Alloy | 3004 |

| Alloy Name | A3004, EN AW-3004 |

| Tempers | O, H12, H14, H16, H18, H22, H24, H26, H28 |

| Thickness | 0.4-3.0 mm |

| Diameter | 100-1500 mm |

| Surface Treatment | Anodized, coated, brushed, etc. |

| Samples | Available |

| MOQ | 1-3 tons |

Chemical Composition of 3004 Aluminum (%)

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Other:Each | Other:Total | Al |

| 3004 | 0.3 | 0.7 | 0.25 | 1.0-1.5 | 0.8-1.3 | - | 0.1 | - | 0.05 | 0.15 | Remainder |

Common Diameters & Thickness

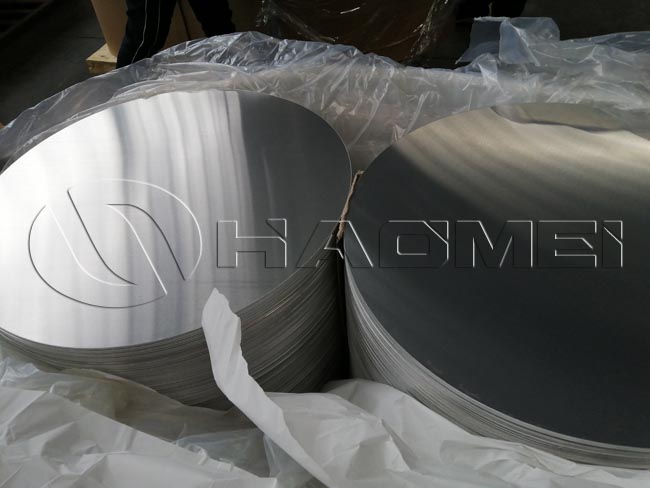

3004 aluminum circle discs are available in various sizes to meet different industry needs:

Thickness: 0.02 in (0.5 mm) to 0.25 in (6.35 mm) - thin sheets for stamping, thicker sheets for structural parts.

Diameter: 3 in (76.2 mm) to 30 in (762 mm) - larger sizes available on request.

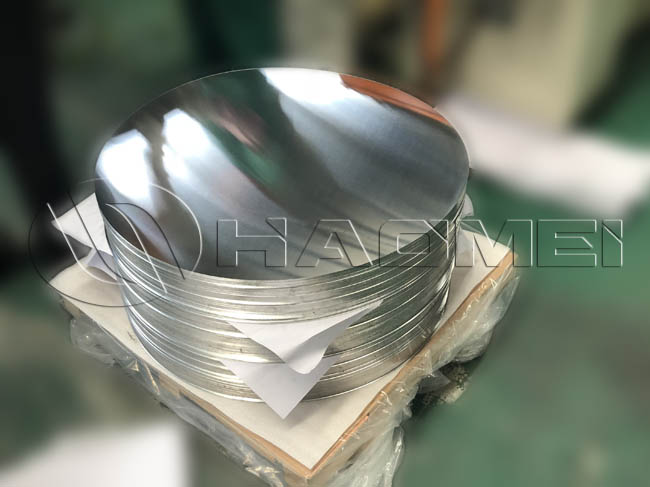

Applications of A3004 Aluminum Circle

Cookware & Household Utensils: Pots (especially inner liners), kettles, food containers, etc.

Chemical Containers: Components for storage and transportation devices, benefiting from excellent corrosion resistance.

Lighting Parts: Lamp caps, housings, reflectors, etc.

Construction & Decoration: Louvers, roofing panels, decorative elements, etc.

Packaging Materials: Most notably, beverage cans (body stock), requiring excellent deep drawing and corrosion resistance.

Others: Heat sinks, pre-painted aluminum coil substrates, electronic and electrical components, etc.

Comparison with Other Aluminum Circles

3004 vs. 1050

Compared with 1050 pure aluminum, 3004 aluminum circle offers higher strength, hardness, and corrosion resistance, while still maintaining good formability. This makes 3004 more suitable for deep drawing and stretching, producing stronger and more durable products. 1050, by contrast, is mainly used in simple containers where strength requirements are low.

3004 vs. 3003

3004 contains 0.8%-1.3% magnesium, giving it higher strength and better corrosion resistance than 3003, although it is slightly more difficult to process. Therefore, 3004 is more suitable for products requiring higher pressure resistance.

3004 vs. 5052

5052 has higher strength and corrosion resistance (especially in marine environments), but its formability is not as good as 3004. This makes 3004 more suitable for complex deep drawing in cookware manufacturing, while 5052 is mainly used for structural parts that require higher strength.

3004 vs. 6061

6061 is a high-strength alloy used in aerospace and automotive parts but has poor formability, making it unsuitable for deep drawing. 3004, on the other hand, excels in plasticity, making it better suited for stamping and drawing applications.

No.14 Waihuan Road, CBD, Zhengzhou, China

No.14 Waihuan Road, CBD, Zhengzhou, China +86-18703635966

+86-18703635966

+86-18703635966

+86-18703635966

sales@alummc.com

sales@alummc.com

8618703635966

8618703635966