-

-

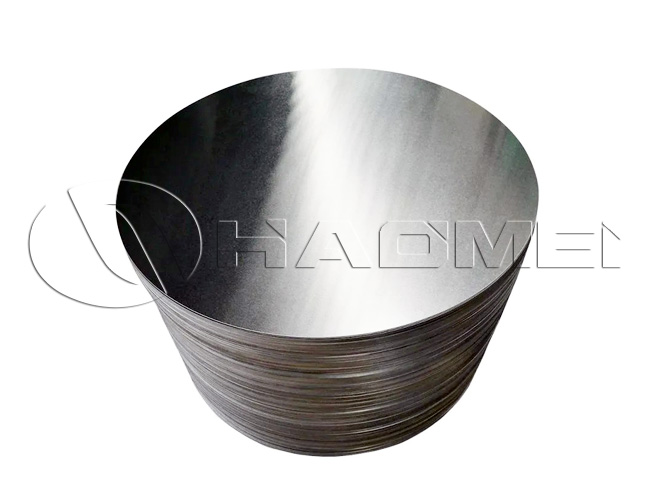

4006 Aluminum Circle

- Alloy 4006

- Tempers H14, O

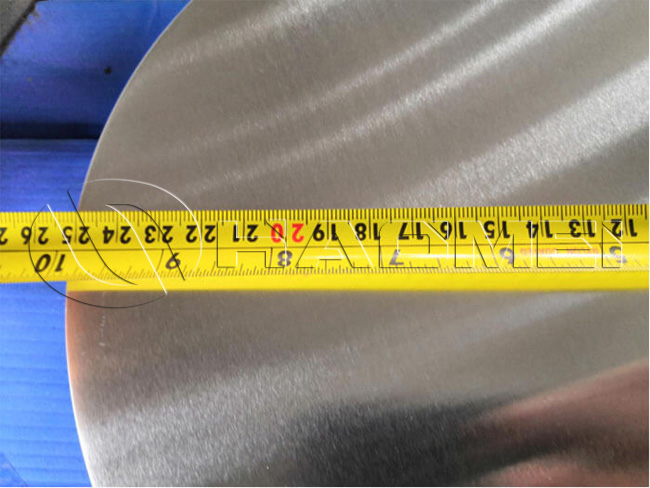

- Thickness 0.8 - 9.0 mm

- Diameter 80 - 1200 mm

- Surface Treatment Anodizing, coating, brushing, etc.

- MOQ 1-3 tons

The 4006 aluminum circle disc belongs to the aluminum-silicon alloy series, a member of the 4000 series. It is well known for its low melting point and excellent welding performance. 4006 aluminum circles are mainly used in applications that require high thermal conductivity or as brazing materials.

Due to its high silicon content, 4006 aluminum requires special surface treatment processes (such as anodizing) to enhance corrosion resistance.

4006 aluminum circles also offer excellent enamelability and good strength, and can undergo deep drawing, spinning, followed by enameling or Teflon coating.

Typical Tempers of 4006 Aluminum Circle

Like many other aluminum alloys, the properties of 4006 can be adjusted by tempering for different applications. Common tempers include:

O (Fully Annealed): Softest condition, maximum ductility, best suited for complex deep drawing and forming.

H14: Moderately strain-hardened, providing increased strength and hardness while maintaining good formability. Frequently used where a balance of hardness and formability is required.

Product Specifications

| Alloy | 4006 |

| Alloy Name | AA4006 |

| Tempers | H22, O |

| Thickness | 0.8 - 9.0 mm |

| Diameter | 80 - 1200 mm |

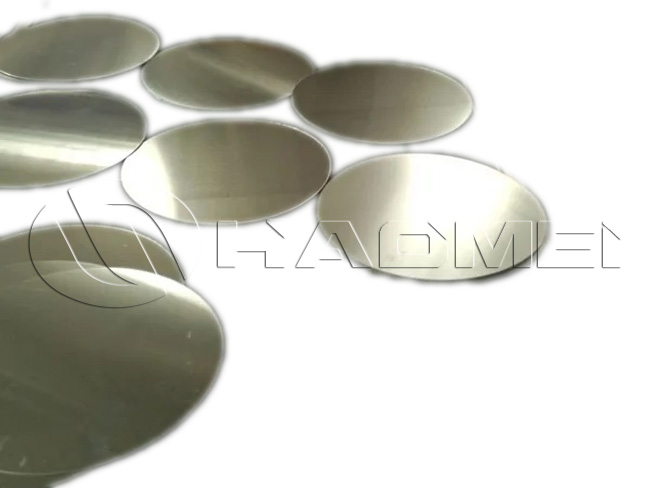

| Surface Finish | Smooth, bright |

| Surface Treatment | Anodizing, coating, brushing, etc. |

| Samples | Available |

| MOQ | 1-3 tons |

Key Features of 4006 Aluminum Circles

Excellent Formability:

As an Al-Si alloy with high silicon content, 4006 resists cracking during stamping, drawing, and spinning, making it suitable for bottle caps, cookware, and lighting components.Good Corrosion Resistance:

Naturally forms a dense oxide film in air, providing reliable resistance to corrosion. Ideal for safe use in food, beverage, and pharmaceutical industries.Stable Chemical Composition:

Uniform alloying, low impurity levels, excellent for subsequent anodizing, printing, or electroplating, ensuring high-quality surface appearance.Lightweight Advantage:

With a density of ~2.7 g/cm³ (one-third of steel), 4006 circles help reduce product weight while maintaining adequate strength, aligning with lightweight design trends in packaging and transportation.Superior Surface Quality:

High smoothness with no cracks, burrs, or inclusions, ensuring good aesthetics and sealing in food-grade packaging.Eco-Friendly & Recyclable:

Non-toxic, safe for food-contact applications, and 100% recyclable, supporting sustainability initiatives.Balanced Mechanical Properties:

Offers a combination of strength, ductility, and plasticity, suitable for high-speed stamping and mass production with high yield rates.

Applications of 4006 Aluminum Circles

Cookware & Kitchenware: Though less common than 3xxx alloys, 4006 is used in certain cookware bottoms due to its heat conduction, ensuring even heating.

Automotive Industry: Applied in manufacturing engine pistons, cylinder liners, rotors, and other parts that operate under high temperature and friction.

Refrigeration & Heat Exchange: Widely used in air conditioner fins, heat exchangers, condensers, benefiting from excellent thermal conductivity and brazing properties.

Wear-Resistant Components: Suitable for wear plates, sliders, bushings, and other mechanical parts.

Special Packaging: Occasionally used in high-temperature-resistant packaging containers.

Comparison with Other Aluminum Circles

4006 vs. 1xxx series (e.g., 1050, 1060):

4006 has higher strength and better wear resistance, though slightly less ductile.

4006 vs. 3xxx series (e.g., 3003, 3005, 3105):

3xxx (Al-Mn alloys) are renowned for corrosion resistance and are widely used in cookware, construction, and traffic signs.

4006 excels in thermal conductivity and brazing, making it more specialized for heat exchange applications.

4006 vs. 5xxx series (e.g., 5052):

5xxx (Al-Mg alloys) are known for high strength and excellent corrosion resistance, especially in marine environments.

They are harder and better for structural parts, while 4006 offers superior weldability and brazing performance.

4006 vs. 6xxx series (e.g., 6061):

6xxx (Al-Mg-Si alloys) can be heat-treated for very high strength.

4006 is often used as a brazing material with 6xxx alloys, complementing each other in manufacturing complex heat dissipation components.

No.14 Waihuan Road, CBD, Zhengzhou, China

No.14 Waihuan Road, CBD, Zhengzhou, China +86-18703635966

+86-18703635966

+86-18703635966

+86-18703635966

sales@alummc.com

sales@alummc.com

8618703635966

8618703635966