No.14 Waihuan Road, CBD, Zhengzhou, China

No.14 Waihuan Road, CBD, Zhengzhou, China

+86-18703635966

+86-18703635966

No.14 Waihuan Road, CBD, Zhengzhou, China

No.14 Waihuan Road, CBD, Zhengzhou, China

+86-18703635966

+86-18703635966

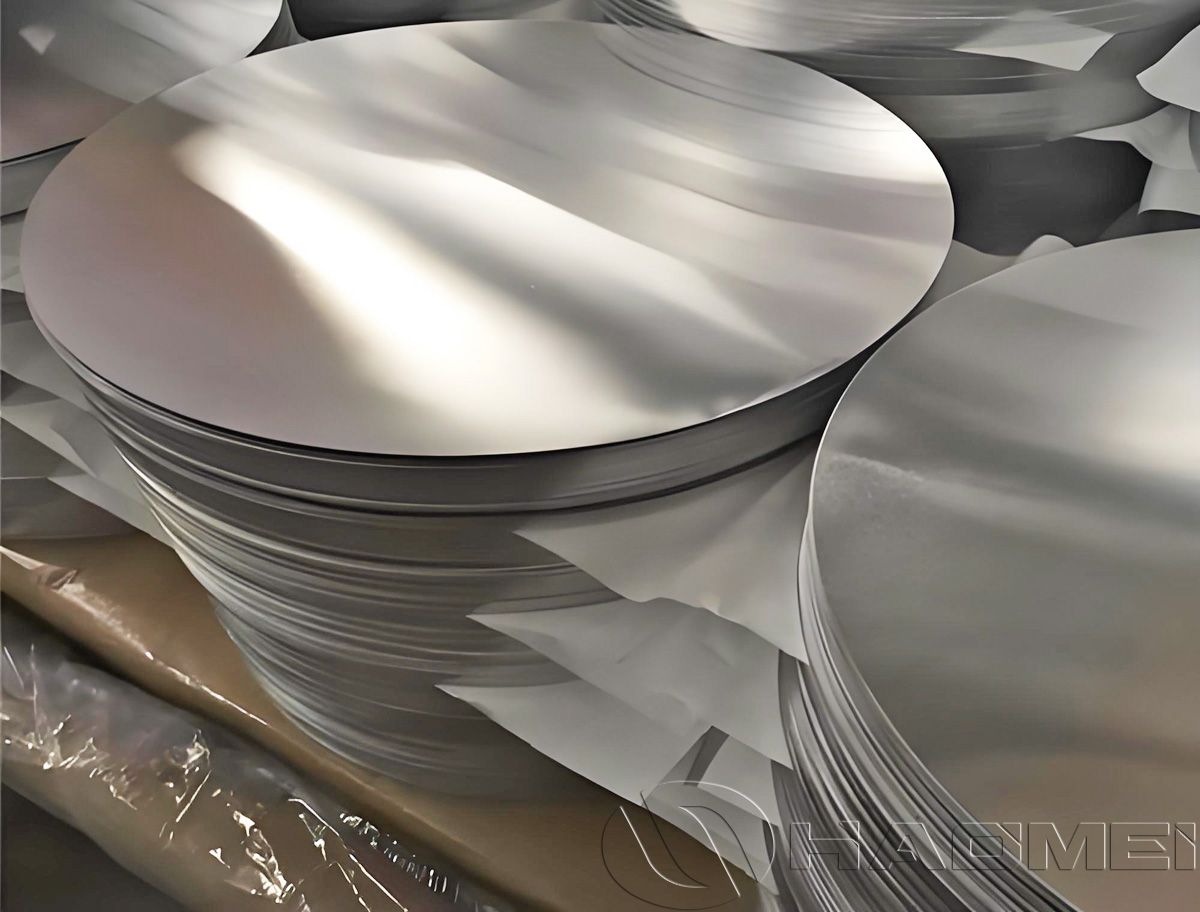

In precision kitchenware manufacturing, aluminum circles serve as the core substrate for non-stick pans. The material properties of these circles directly affect cooking performance and product lifespan. On the market, the most commonly used aluminum circles for non-stick cookware are 1070 pure aluminum circles and 3003 aluminum alloy circles.

The 1070 aluminum circle is classified as industrial pure aluminum, with a high purity of over 99.7%. It offers excellent electrical and thermal conductivity, and is highly ductile, making it suitable for deep drawing and stamping without cracking. It is also used in electrical components, heat sinks, and other applications requiring high conductivity.

Chemical Composition (%)

| Alloy | Al | Fe | Si | Cu | Mn | Mg | Zn | Ti | V | Others |

| 1070 | ≥99.7% | ≤0.25 | ≤0.20 | ≤0.04 | ≤0.03 | ≤0.02 | ≤0.04 | ≤0.03 | ≤0.05 | ≤0.15 |

Mechanical Properties

| Yield Strength | ≥ 30 MPa |

| Tensile Strength | ≥ 70 MPa |

Elongation: | ≥ 35% |

Physical Properties

| Density | 2.70 g/cm³ |

| Thermal Conductivity | ≈ 235 W/(m·K) |

The 3003 aluminum circle is an aluminum-manganese alloy (Mn content 1.0–1.5%) with higher strength than pure aluminum, while retaining good corrosion resistance and ductility. It is commonly used in cookware, lighting housings, and other products requiring a balance of lightweight and corrosion resistance.

Chemical Composition (%)

| Alloy | Fe | Si | Cu | Mn | Mg | Zn | Ti | Other:Each | Other:Total | Al |

| 3003 | 0.7 | 0.6 | 0.05-0.20 | 1.0-1.5 | - | 0.1 | 0.025 | 0.15 | 0.05 | remainder |

Mechanical Properties (H14 - Half-Hard)

| Yield Strength | ≥ 110 MPa |

| Tensile Strength | ≥ 145 MPa |

| Elongation | ≥ 12% |

Physical Properties

| Density | 2.73 g/cm³ |

| Thermal Conductivity | ≈ 160–180 W/(m·K) (slightly lower than 1070) |

1. Heat Conductivity and Cooking Performance

1070 Aluminum Circle: Offers excellent and uniform heat distribution, rapidly heating the pan bottom. Ideal for high-end non-stick cookware prioritizing thermal conductivity.

3003 Aluminum Circle: Heat conductivity is slightly lower, but pan thickness can be adjusted to maintain uniform temperature distribution. Suitable for mid-range non-stick pans.

2. Forming and Processing

1070: High ductility, suitable for ultra-thin pan bottoms or complex shapes. Deep drawing can reach 80–100mm without cracking.

3003: Higher strength, suitable for thicker bottoms or composite bases, preventing deformation and springback during processing.

3. Corrosion Resistance and Service Life

1070: Pure aluminum has moderate oxidation resistance. Requires protective coatings such as PTFE or ceramic non-stick layers to extend service life.

3003: Alloying increases corrosion resistance, making it less prone to discoloration or chemical attack from acidic or alkaline foods.

4. Production Process

3003: Requires precise process control. To achieve optimal deep drawing, homogenization is needed to distribute alloying elements uniformly, and annealing temperature must be strictly controlled to obtain the desired soft state.

1070: Process is simpler due to single-element composition. Main goal is annealing to eliminate work hardening and restore excellent ductility.

5. Cost and Value

1070: Preferred for premium cookware due to superior thermal conductivity, but material cost is higher and processing is more challenging.

3003: Common for mid-to-high-end cookware, offering a balance of strength and formability, with better cost-performance ratio.

Conclusion:

1070 aluminum circles are ideal for premium cookware emphasizing light weight, fast heat transfer, and complex shapes.

3003 aluminum circles are better suited for durable, thick-bottom, or composite non-stick pans, balancing strength, corrosion resistance, and cost-efficiency.

Copyright © 2026 By HAOMEI Aluminum CO., LTD. All Rights Reserved. Sitemap