-

-

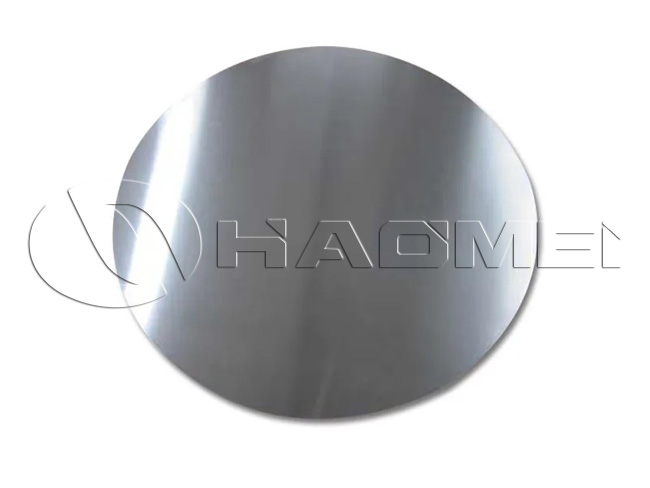

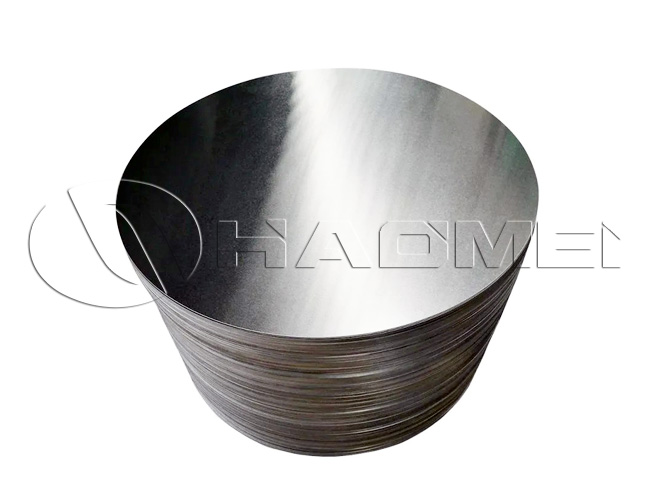

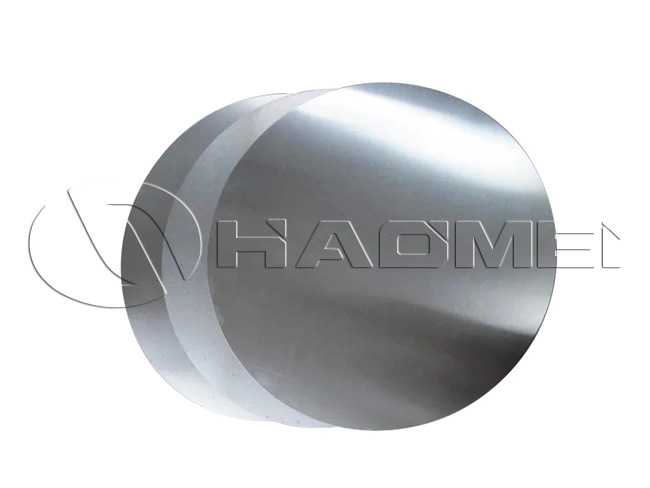

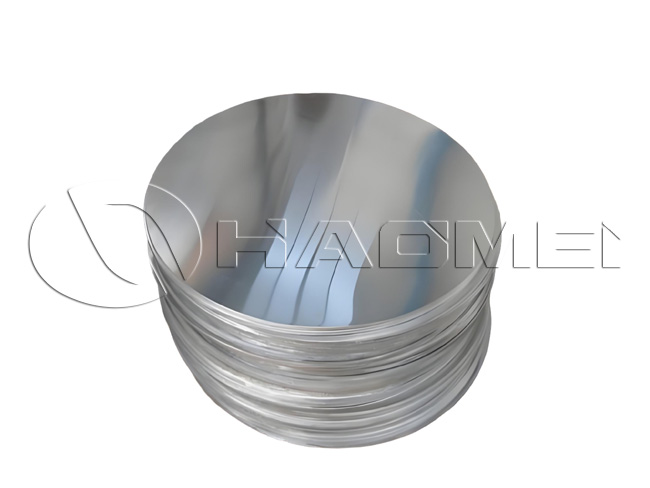

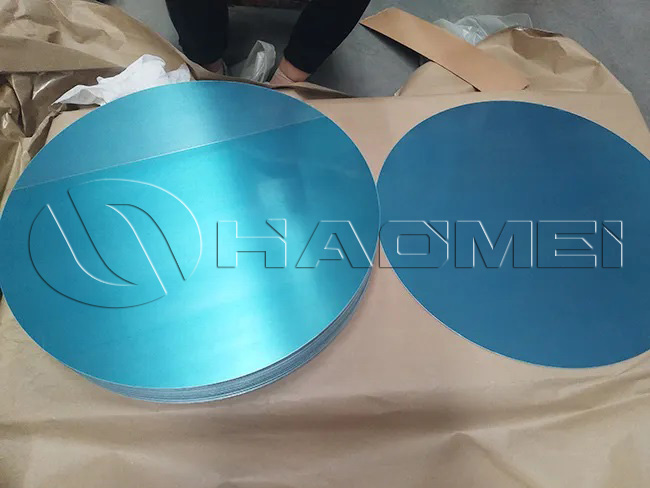

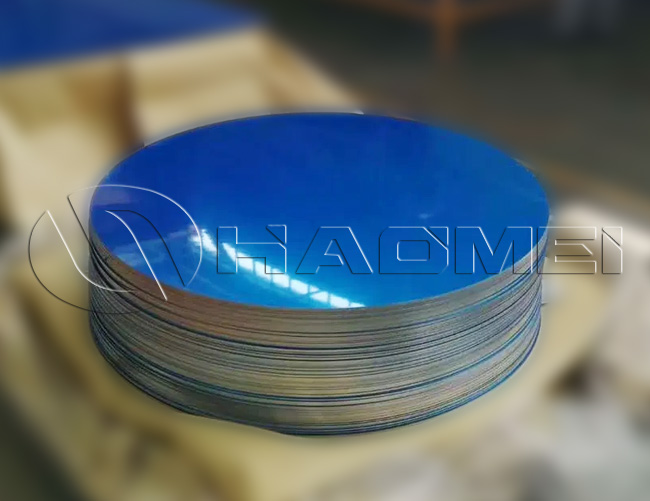

1070 Aluminium Circle

- Alloy 1070

- Temper O, H12, H14, H16, H18

- Thickness 0.36mm - 5mm

- Diameter 120mm - 1000mm

- Surface finish Anodized, coated, etc.

- MOQ 1-3 tons

1070 aluminium circle is a circular product made from industrial pure aluminium (Al content ≥ 99.7%) through precision stamping or cutting processes.

It offers high plasticity, corrosion resistance, and excellent electrical and thermal conductivity, making it suitable for deep drawing, bending, welding, and other processing methods. It is widely applied in food packaging, architectural decoration, electronics & electrical appliances, and chemical industries.

CC/DC Processing of 1070 Aluminium Circle

Continuous Casting (CC): Molten aluminium is poured into a mold and then processed through a continuous casting machine to produce aluminium sheets or circles. CC is well-suited for large-scale production, ensuring uniform and smooth surfaces. Circles made by CC are often used for spinning applications.

Direct Casting (DC): Refers to directly casting individual aluminium discs. DC is suitable for highly customized and precise size requirements, often applied in small-batch or special-purpose manufacturing.

Advantages of 1070 Aluminium Circles

1. High purity: With extremely high purity, 1070 provides outstanding electrical and thermal conductivity, ranking among the top within all aluminium alloys.

2. Excellent ductility: Exceptional elongation, formability, and deep-drawing properties. It is particularly suitable for complex stretching and stamping without cracking.

3. Superior corrosion resistance: A dense oxide film naturally forms on the pure aluminium surface, effectively protecting against corrosion.

4. Eco-friendly and recyclable: 100% recyclable and compliant with EU RoHS directives.

5. Cost-effective: Industrial pure aluminium is less expensive than alloyed aluminium, making it ideal for large-scale industrial applications.

Specifications of 1070 Aluminium Discs

| Alloy | 1070 |

| Designation | A99.7, Al99.7, A1070 |

| Temper | O, H12, H14, H16, H18 |

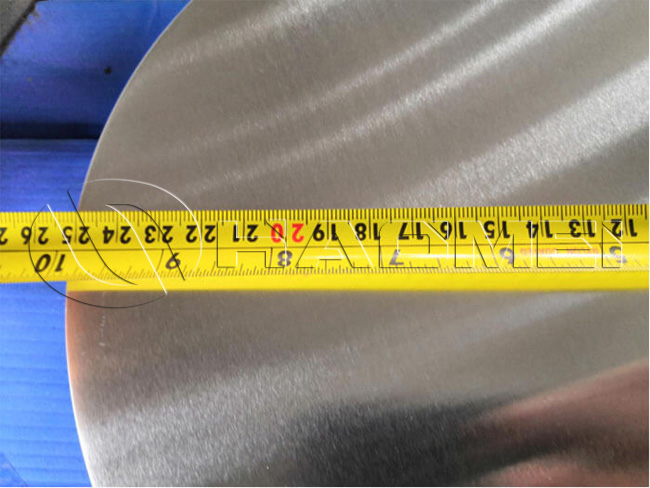

| Thickness | 0.36mm - 5mm |

| Diameter | 120mm - 1000mm |

| Forms | Circle, sheet, coil, plate, strip |

| Density | 2.7 g/cm³ |

| Processing methods | DD, DC |

| Surface finish | Anodized, coated, etc. |

| Packaging | Export standard, wooden pallet |

| MOQ | 500 kg per size |

Mechanical Properties

| Temper | Thickness (mm) | Tensile Strength (MPa) | Elongation (%) | Standard |

| O | 0.36-5 | 60-100 | ≥20 | GB/T91-2002 |

| H12 | 0.5-5 | 70-120 | ≥4 | |

| H14 | 0.5-5 | 85-120 | ≥2 |

Chemical Composition of 1070 Aluminium (%)

| Alloy | Al | Fe | Si | Cu | Mn | Mg | Zn | Ti | V | Others |

| 1070 | ≥99.7% | ≤0.25 | ≤0.20 | ≤0.04 | ≤0.03 | ≤0.02 | ≤0.04 | ≤0.03 | ≤0.05 | ≤0.15 |

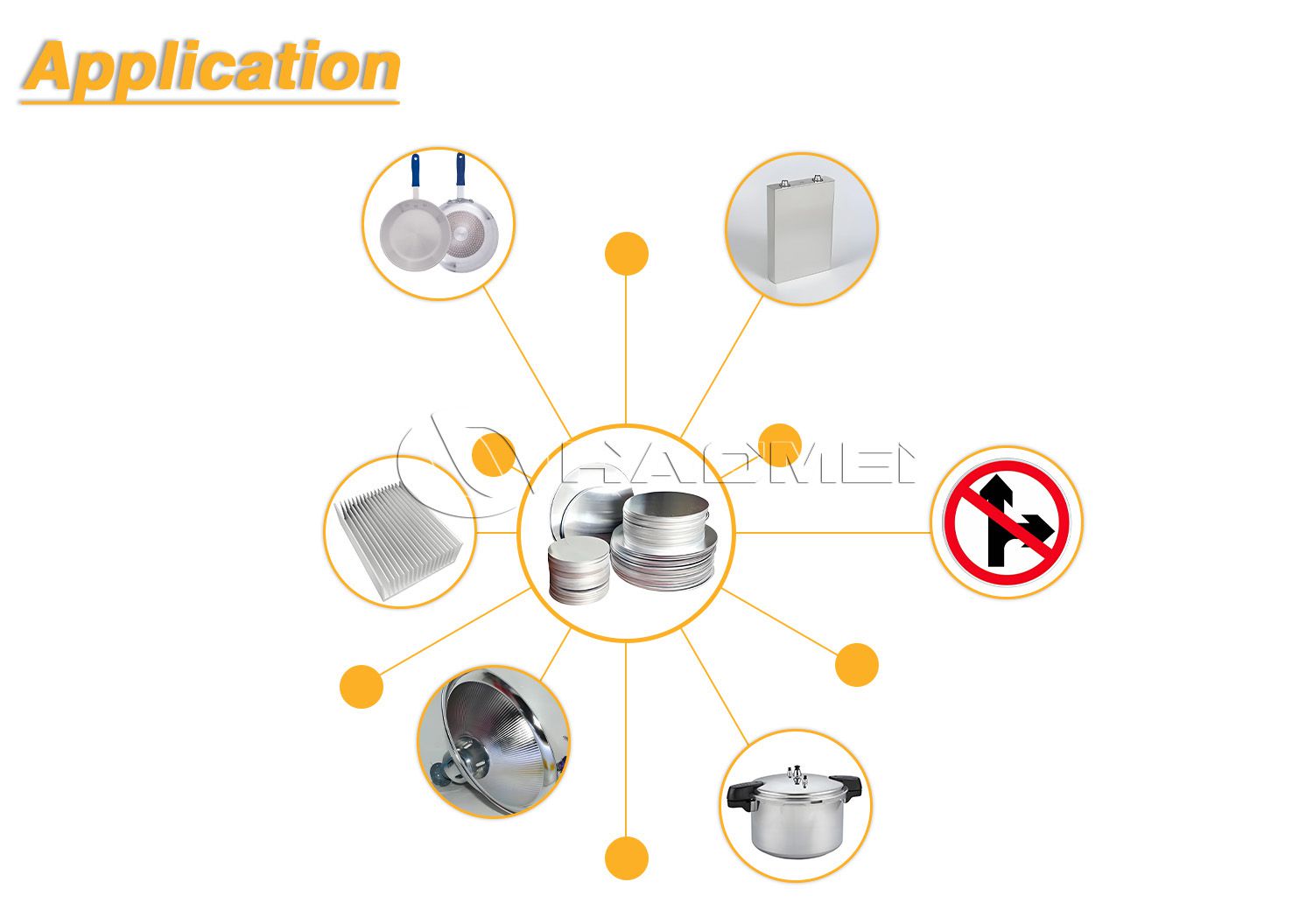

Applications of A1070 Aluminium Circle

Electronics: Used for enclosures of electronic devices requiring high conductivity.

Heat dissipation: Applied in radiators, lighting fixtures, and other heat-dissipating products.

Decorative items: Processed into reflectors, ornaments, etc.

Household utensils: Raw material for pots, kettles, and other cookware (benefiting from high thermal conductivity).

Labels and nameplates: Used for producing nameplates, tags, and identification plates for equipment.

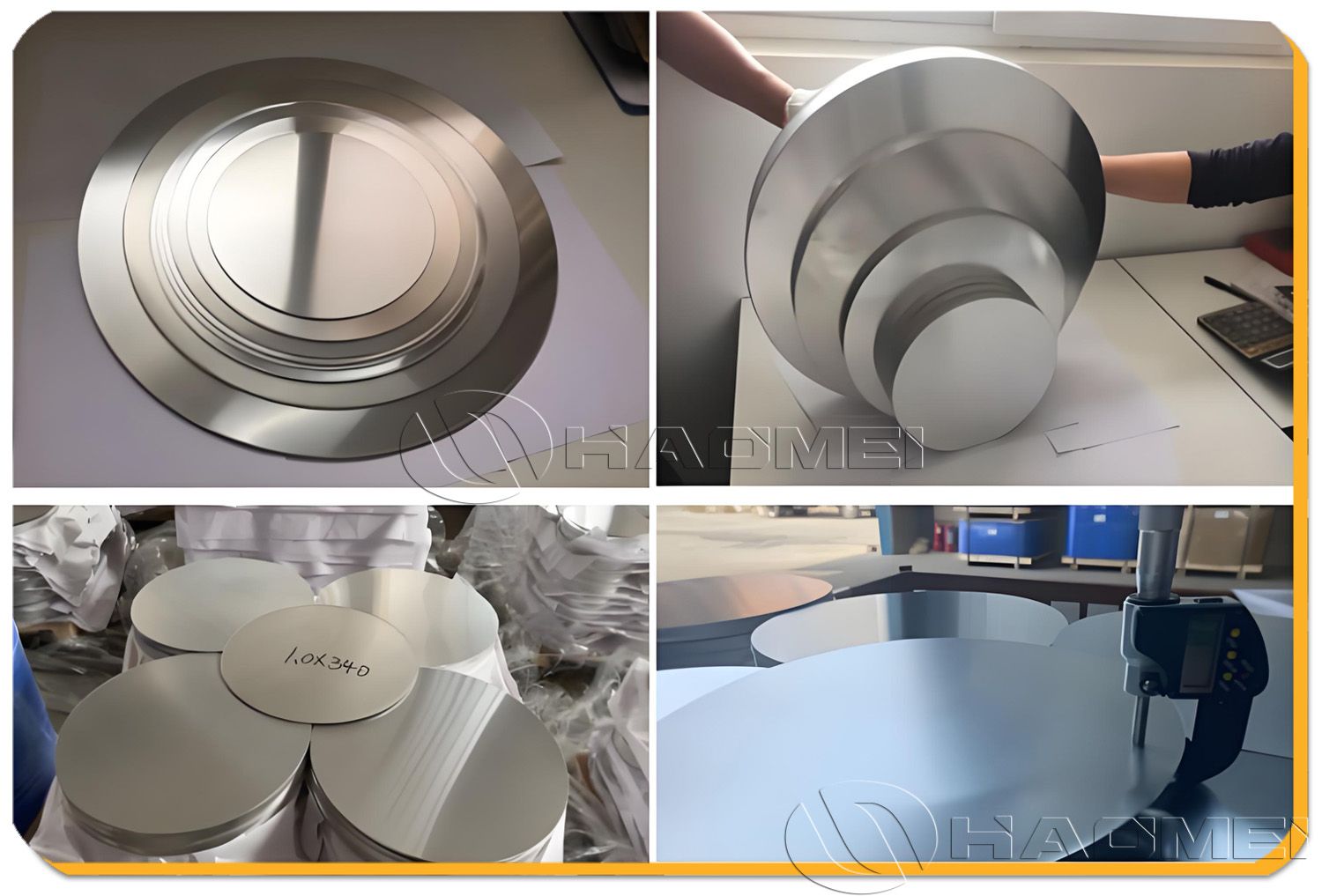

Quality Control System for Aluminium Circles

Ensure excellent surface quality - free from visible scratches, oil stains, oxidation, or black spots.

For discs with thickness >0.5 mm, ensure smooth and burr-free edges.

Strict grain size and elongation control at the coil stage to guarantee excellent deep drawing and spinning performance, preventing defects such as wire-drawing marks, wrinkling, or high ear rate during subsequent processing.

Pricing of 1070 Aluminium Circles

The price of 1070 aluminium circles is influenced by aluminium ingot market prices, product specifications, order volume, temper requirements, and surface treatment methods. A specific quotation must be obtained from the supplier.

Comparison with Other Aluminium Circles

1060 vs. 1070: 1070 has higher purity, providing better electrical conductivity and superior surface finishing properties, making it more suitable for applications requiring high electrical performance or mirror polishing.

1070 vs. 3003: 1070 offers better formability, while 3003 (with manganese addition) has stronger anti-rust properties, commonly used in outdoor and construction applications.

1070 vs. 5xxx series (5052, 5754, etc.): The 5-series alloys provide much higher strength and corrosion resistance, making them ideal for ships, automotive, and pressure vessels. However, 1070 remains superior in ductility and deep drawing performance.

Why Choose Us?

1. Professional manufacturer with 20 years of experience

2. Waterproof and scratch-resistant products

3. Customizable shapes, designs, and dimensions as per customer requirements

4. Competitive price, high quality, durability, and fast delivery

5. Small orders are welcome

No.14 Waihuan Road, CBD, Zhengzhou, China

No.14 Waihuan Road, CBD, Zhengzhou, China +86-18703635966

+86-18703635966

+86-18703635966

+86-18703635966

sales@alummc.com

sales@alummc.com

8618703635966

8618703635966