-

-

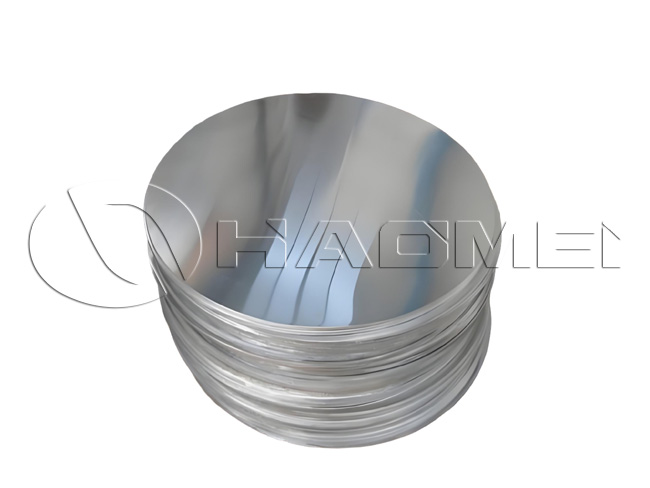

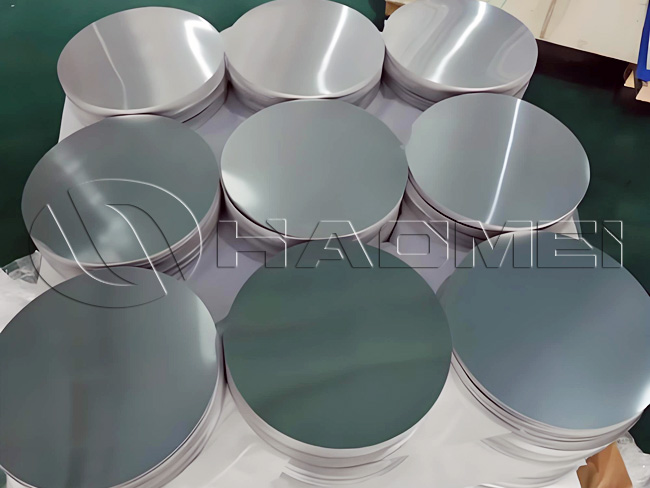

Aluminum Circle Discs for Traffic Signs

- Alloy 1050, 1100, 3003, 5052, etc.

- Tempers H14, H16, H32, H34, etc.

- Diameter 50 - 1200 mm

- Thickness 0.5 - 6.0 mm

- Production Method CC / DC

- Shapes Available Round, square, rectangular, triangular, pentagonal, octagonal

- MOQ 1 - 3 tons

History of Aluminum Traffic Signs

In the 19th century, traffic signs were mainly made of wood and iron plates. However, wood lacked durability, and iron was heavy and prone to rust-making them less ideal materials.

By the mid-1940s, Connecticut, USA, pioneered the use of aluminum for vehicle license plates, highlighting its superior weather resistance and ease of maintenance. From then on, aluminum was gradually considered for traffic signage applications.

From the mid-to-late 20th century, aluminum traffic signs spread rapidly across developed countries. Today, aluminum accounts for over 90% of all road signs worldwide.

What Are Aluminum Discs for Road Signs?

Aluminum circle discs for traffic signs are an essential component in road safety and traffic management. These discs-commonly called road sign plates-are round aluminum sheets widely used on highways, urban streets, and specialized roads. They serve multiple functions such as guidance, direction, warning, caution, and information display.

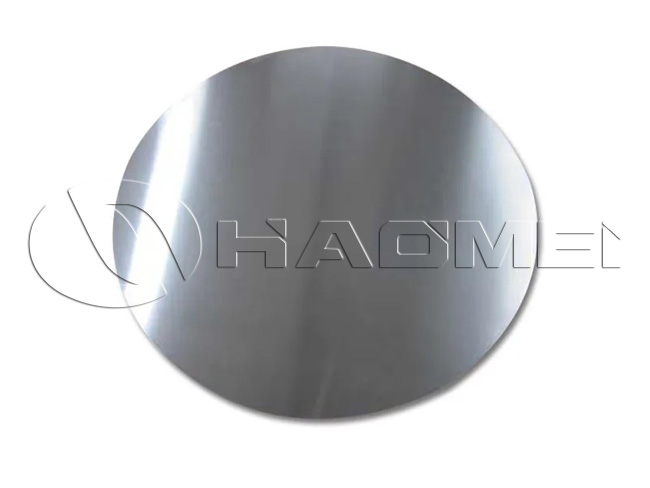

Aluminum circles are not only lightweight, strong, and corrosion-resistant, but they also bond well with reflective films, coatings, and paints, ensuring traffic signs remain clear and durable in outdoor environments.

Commonly Used Alloys for Aluminum Discs for Road Signs

1050/1060/1100 Aluminum Traffic Signs

1000-series aluminum discs contain over 99.0% aluminum, are relatively soft, have good ductility, and excellent processability. They are lightweight and low-cost, making them commonly used in areas with favorable climates and suitable for economical traffic sign production. They are typically used in H14 or H24 steel. Annealing results in a clean, smooth surface that is easy to paint or laminate.

3003 Aluminum Discs for Road Signs

3003 aluminum alloy, due to its manganese content, offers improved corrosion and oxidation resistance, and boasts higher strength than pure aluminum. It is commonly used on roads requiring high quality, particularly in coastal areas or environments with strong winds, effectively extending the service life of traffic signs.

5052 Aluminum Discs for Traffic Signs

5052 aluminum discs offer superior strength and corrosion resistance, as well as excellent wear resistance and thermal conductivity. They are suitable for long-term outdoor use, especially in areas with complex climates and strong winds. For example, the 5052 H38 grade commonly used in the United States offers high hardness and a smooth surface, remaining stable and undeformed even in hurricane-force winds and stormy weather.

5454 Aluminum Traffic Signs

5454 aluminum discs perform particularly well in regions with harsher maritime climates. Its rust resistance is approximately 20% better than 5052, making it more resistant to seawater corrosion. Therefore, it is widely used in Europe and coastal countries to manufacture high-strength, highly corrosion-resistant traffic signs.

5754 Aluminum Traffic Signs

5754 aluminum discs offer moderate strength, good corrosion resistance, and excellent weldability and formability, all at a more economical price than 5454. They are also suitable for countries and regions near coastal areas, effectively resisting corrosion caused by salt in the air. They offer a durable and cost-effective material for traffic signs.

Product Information - Aluminum Wafers for Traffic Signs

| Alloys | 1050, 1100, 3003, 5052, etc. |

| Tempers | H14, H16, H32, H34, etc. |

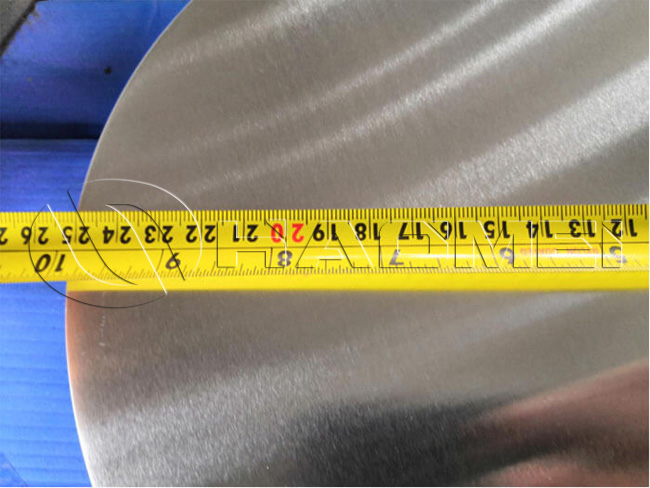

| Diameter (mm) | 50 - 1200 |

| Thickness (mm) | 1.0 - 3.0 |

| Tolerance Control | Thickness ±0.05 mm, roundness ≤0.5 mm |

| Production Method | CC (continuous casting) & DC (direct casting) |

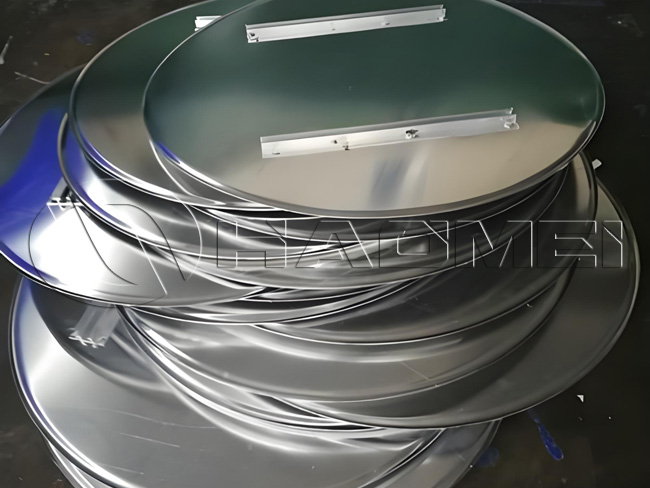

| Further Processing | Deep drawing, spinning, anodizing |

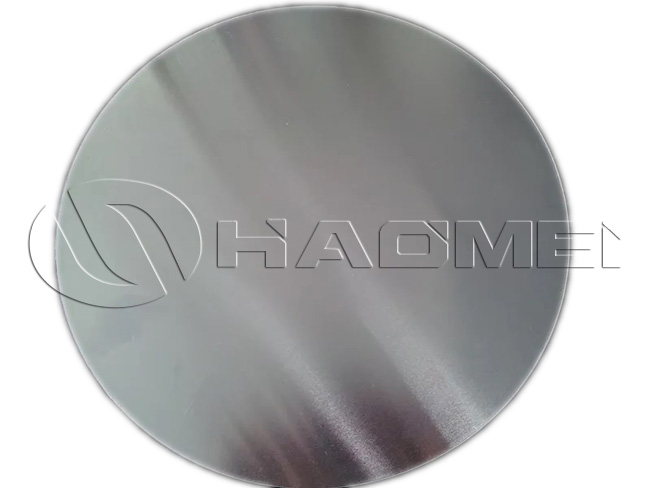

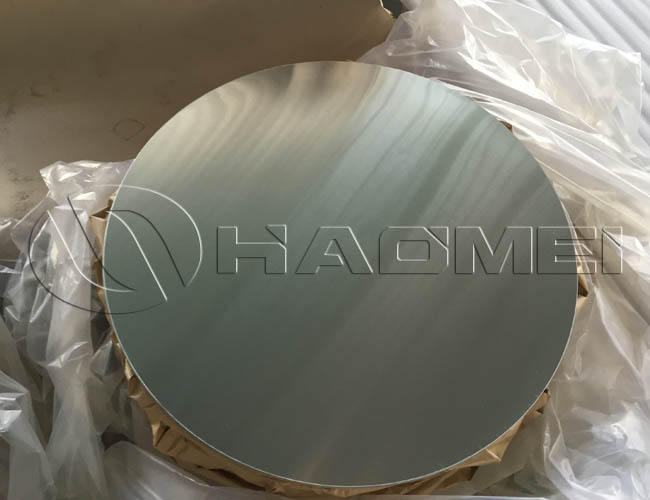

| Surface Treatments | Mill finish, chemical degreasing, anodizing, color coating |

| Shapes Available | Round, square, rectangular, triangular, pentagonal, octagonal |

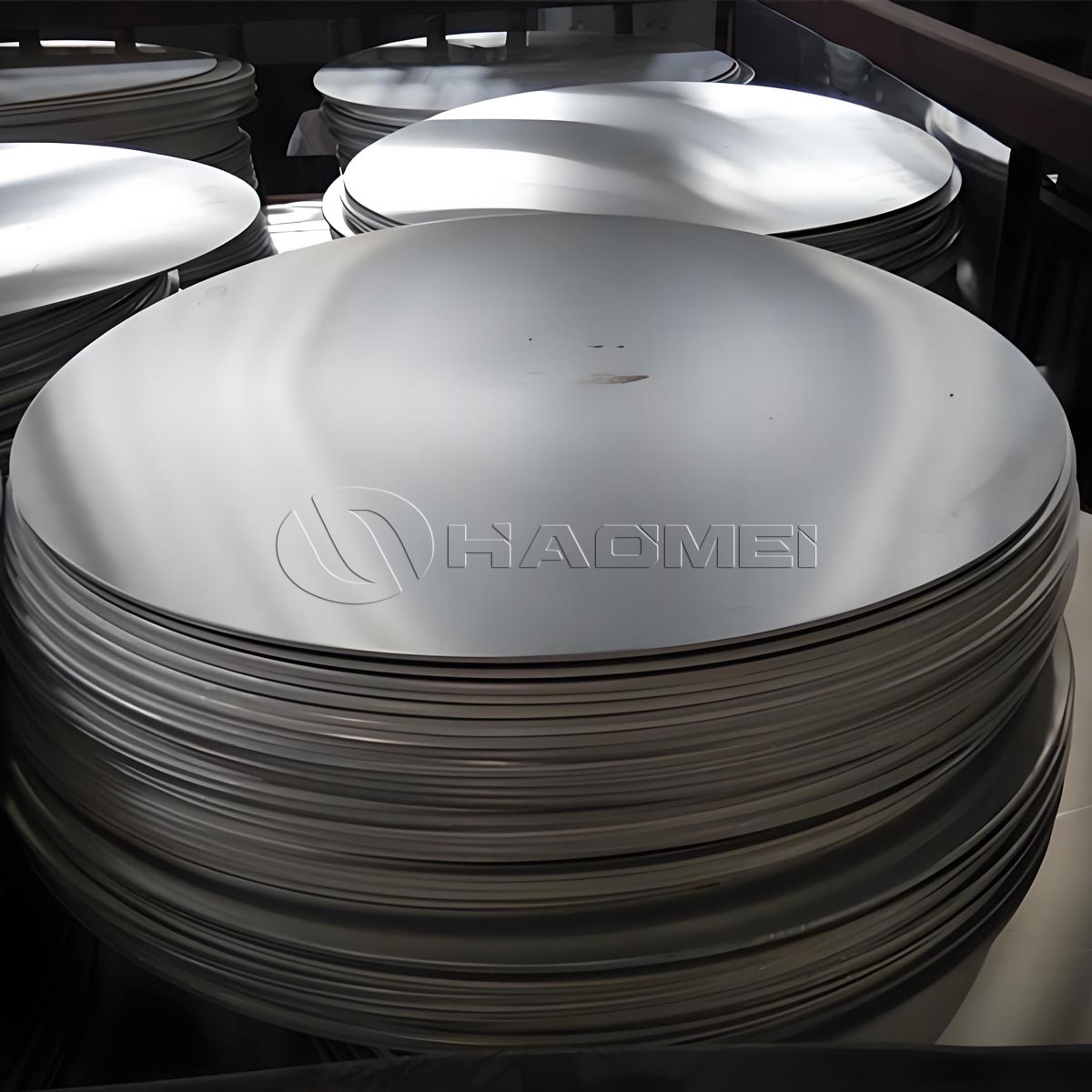

| MOQ | 1-3 tons |

Why Choose Aluminum Discs for Traffic Signs?

High weather & corrosion resistance : withstand rain, UV rays, and salt spray.

Strength & rigidity : ensures stability under wind loads.

Excellent flatness : allows smooth application of reflective film without bubbles or wrinkles.

Lightweight : easier to transport and install, reduces structural load.

Good workability : easy to cut, bend, and punch.

Bright colors : powder-coated for vivid, long-lasting appearance.

Non-magnetic : aluminum signs do not interfere with instruments or devices.

Easy to clean & maintain : aluminum surfaces remain shiny after simple washing.

Long service life : retains shape and color for 15-20 years.

Eco-friendly & recyclable - supports sustainability and green development.

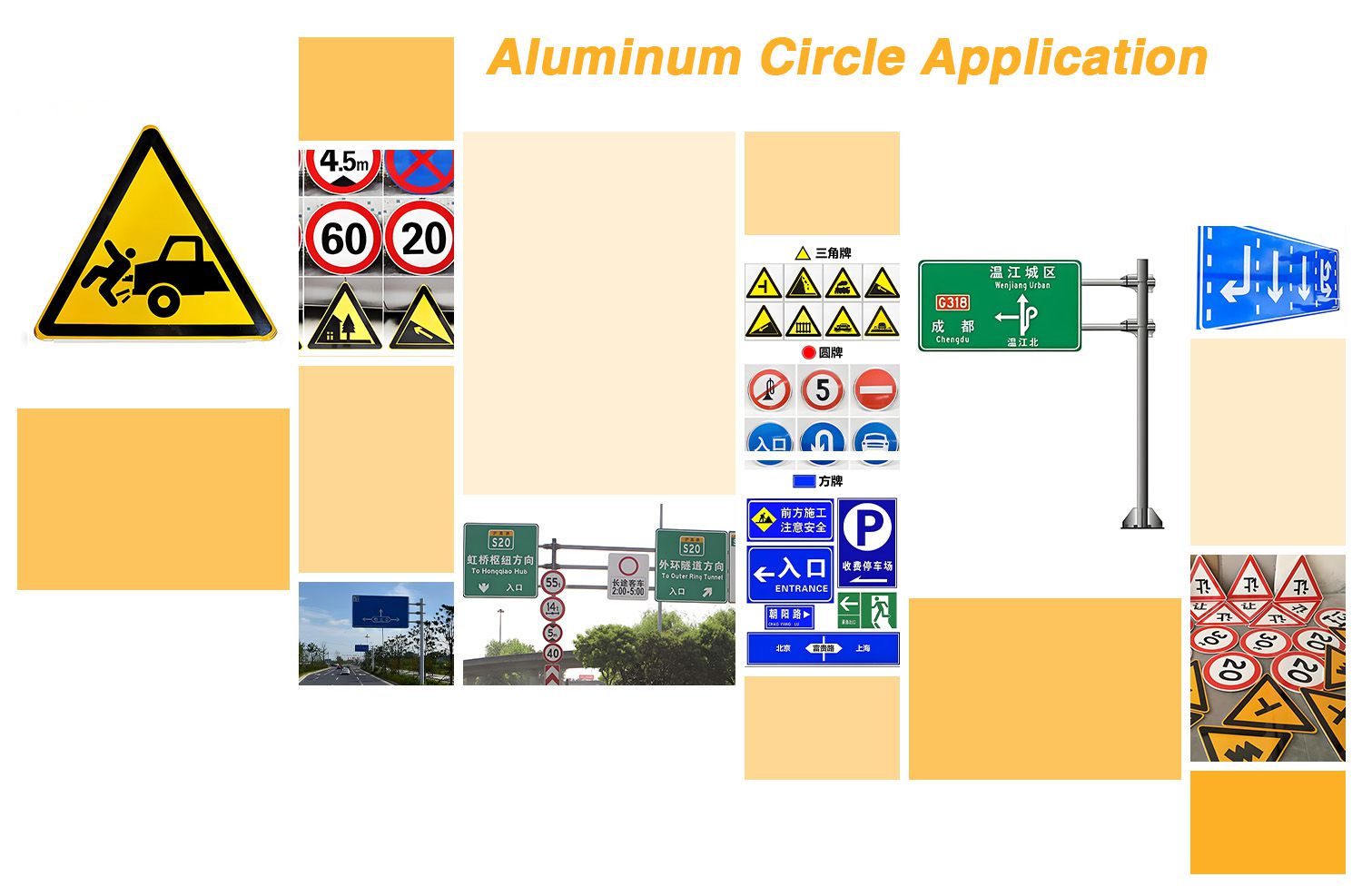

Applications of Aluminum Discs

Road Traffic Signs: Highway, urban, rural directional, warning, and speed limit signs.

Municipal Signage: Street name plates, parking signs, tourism direction signs.

Advertising & Display Boards: Public facility billboards, corporate signage, announcement boards.

Role of Aluminum Discs in Road Safety

Enhanced visibility: Reflective films ensure nighttime and low-light clarity.

Weather durability: Resistant to corrosion, ensuring long-term clarity and function.

Easy installation & replacement: Lightweight material simplifies handling on-site.

Why Choose Us?

1. Premium raw materials: High-purity alloys compliant with international standards.

2. Complete customization: Diameter, thickness, and temper tailored to customer needs.

3. Advanced production: Precision stamping, annealing, and finishing processes ensure smoothness and quality.

4. Strict quality control: Testing for thickness, roundness, mechanical properties, and corrosion resistance.

5. Trusted worldwide: Exported to Europe, America, Southeast Asia, and the Middle East.

6. Competitive value: High-quality products at competitive prices with efficient logistics services.

No.14 Waihuan Road, CBD, Zhengzhou, China

No.14 Waihuan Road, CBD, Zhengzhou, China +86-18703635966

+86-18703635966

+86-18703635966

+86-18703635966

sales@alummc.com

sales@alummc.com

8618703635966

8618703635966