No.14 Waihuan Road, CBD, Zhengzhou, China

No.14 Waihuan Road, CBD, Zhengzhou, China

+86-18703635966

+86-18703635966

No.14 Waihuan Road, CBD, Zhengzhou, China

No.14 Waihuan Road, CBD, Zhengzhou, China

+86-18703635966

+86-18703635966

1050 H24 aluminum refers to 1050 aluminum alloy in H24 temper, which means the aluminum alloy is strain-hardened and partially annealed to a condition halfway between the annealed (O) and full-hard (H28) states. In this state, the material gains moderate strength while retaining good ductility.

1050 aluminum circle discs belong to the 1 series of pure aluminum, with an aluminum content of 99.5%. It retains the silvery white glass and light weight of pure aluminum, as well as excellent weldability, ductility, surface reflectivity, corrosion resistance and electrical conductivity.

High Purity: Belonging to the pure aluminum series, 1050 has an aluminum content of over 99.50%, ensuring excellent conductivity, thermal conductivity, and corrosion resistance.

Good Formability: In H24 temper, the circles combine moderate strength with excellent formability. This makes 1050 H24 aluminum circles highly suitable for stamping, deep drawing, bending, and spinning into complex shapes.

Corrosion Resistance: The natural oxide film formed on the surface of pure aluminum provides an effective barrier against atmospheric corrosion and moisture.

Excellent Anodizing Quality: When anodized, 1050 H24 aluminum circle discs offers an attractive surface finish with enhanced corrosion resistance and reflectivity.

| Alloy | 1050 |

| Temper | H14, O, H24,etc |

| Aluminum content | ≥ 99.5% |

| Common thickness | 0.5mm - 5.0mm |

| Diameter range | 100mm - 1500mm |

| Production process | Hot rolled, cold rolled |

| Circle type | Hot-rolled circle, cold-rolled circle, precision-processed circle |

| Surface finish | Mill finish, customized surface treatment upon request |

| Coating options | PVC coating, color coating, polyester coating, PVDF coating, polyurethane coating, epoxy coating |

| Applications | Cookware, lighting, traffic signs, etc. |

| MOQ | 1-3 tons |

| Tensile strength | 105-145 MPa |

| Yield strength | ≥95 MPa |

| Elongation (δ10) | ≥3% |

| Density | 2.71 g/cm³ |

| Thermal conductivity | ~222 W/m·K |

| Electrical conductivity | ≥61% IACS |

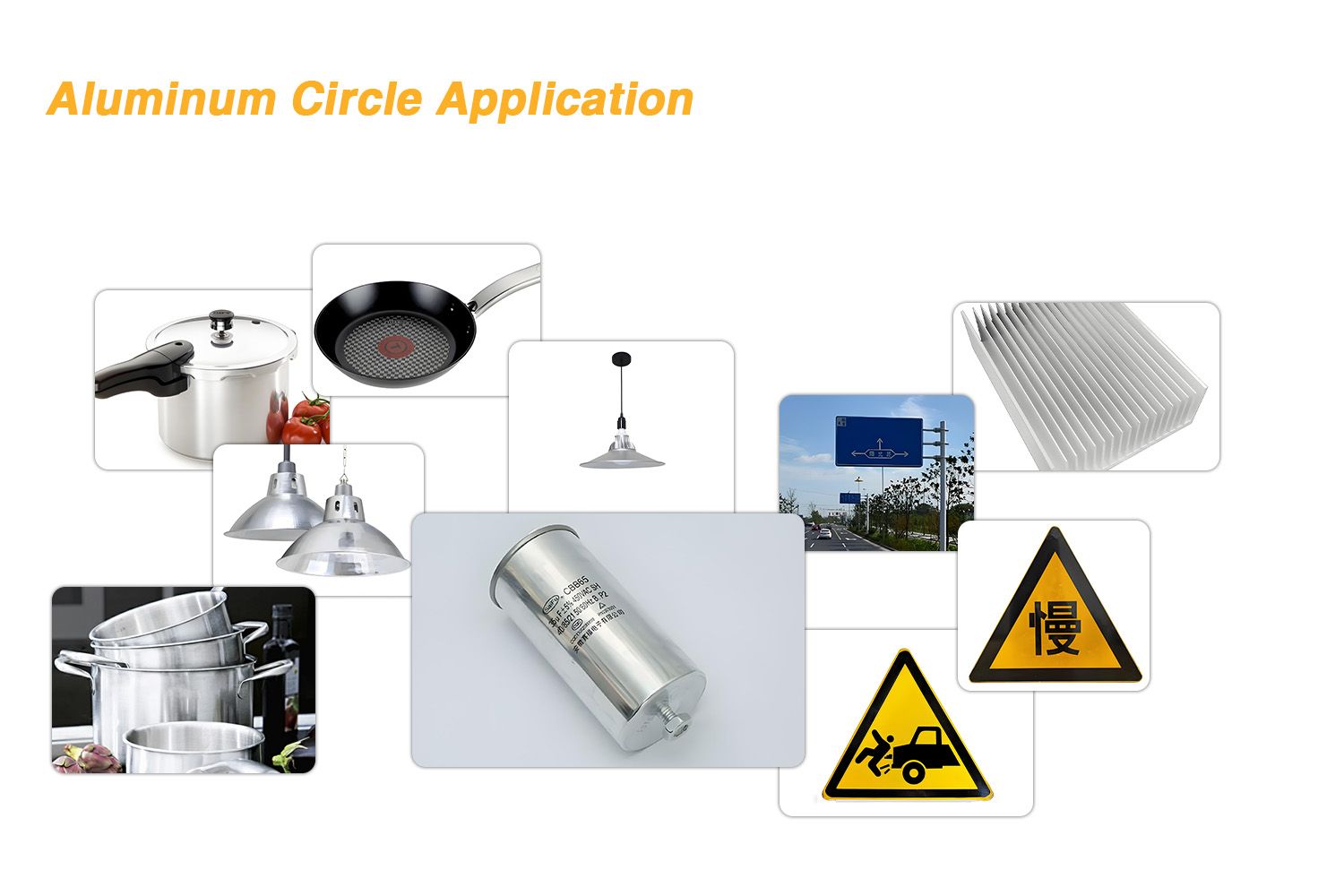

Thanks to its deep drawing and spinning properties, corrosion resistance, and cost-effectiveness, 1050 H24 aluminum circle is widely used in:

Cookware & Kitchenware: Pots (such as frying pans, pressure cookers, and non-stick cookware), bowls, plates, and other utensils requiring deep drawing.

Lighting Accessories: Lamp reflectors, lamp holders, lamp covers, and reflective plates.

Traffic Facilities: Road traffic sign boards.

Electrical Components: Rice cooker shells, kettle bodies, capacitor casings, and similar enclosures.

Others: Building decoration panels, bottle caps, trademarks, and nameplates.

1. Raw Material Selection

High-quality aluminum ingots are processed into 1050 aluminum coils through hot and cold rolling. The raw materials must be pure and have a uniform microstructure.

2. Rolling Process

Hot Rolling: Aluminum ingots are heated to 500-530°C and rolled into initial slabs.

Cold Rolling: Further reduced to the required thickness (0.4-6.0mm) with excellent flatness.

3. Intermediate Annealing

To restore ductility and prevent cracking during stamping, cold-rolled sheets undergo annealing to soften the material while retaining sufficient strength.

4. Blanking into Circles

High-speed punching machines or circle cutting equipment cut the aluminum coils into round discs with diameters of 100-1000mm and thicknesses of 0.4-5mm.

5. Surface Treatment & Inspection

Processes include deburring, degreasing, and cleaning to ensure a smooth surface.

Online eddy current testing or surface scanning eliminates defects such as scratches, dents, or oxide spots.

6. Final Packaging

Products are packed with moisture-proof paper and wooden pallets to prevent scratches and oxidation during transportation.

Copyright © 2026 By HAOMEI Aluminum CO., LTD. All Rights Reserved. Sitemap