No.14 Waihuan Road, CBD, Zhengzhou, China

No.14 Waihuan Road, CBD, Zhengzhou, China

+86-18703635966

+86-18703635966

No.14 Waihuan Road, CBD, Zhengzhou, China

No.14 Waihuan Road, CBD, Zhengzhou, China

+86-18703635966

+86-18703635966

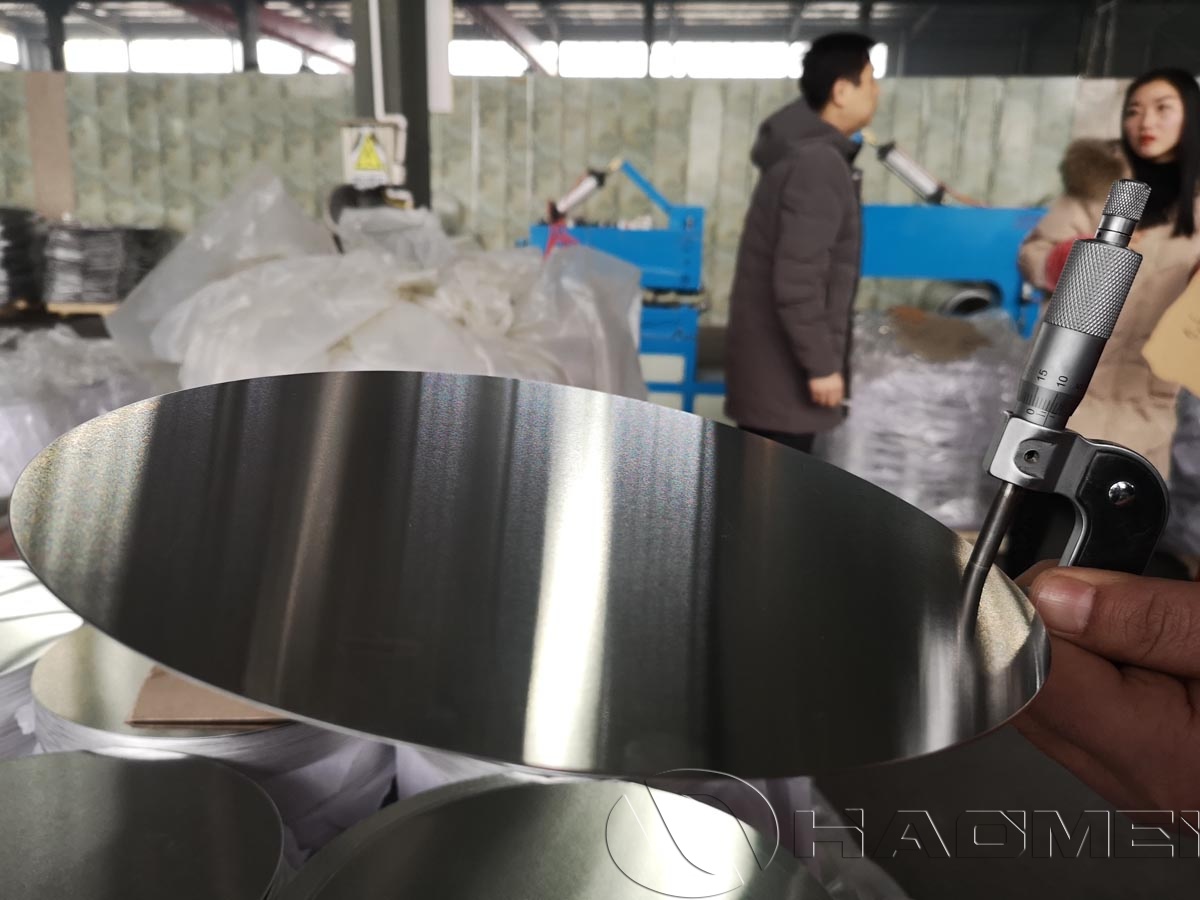

Lighting manufacturers and sourcing teams often face recurring issues when selecting aluminum discs: inconsistent thickness that causes wobble during spinning, surface marks that telegraph through anodized finishes, edge burrs that crack during deep drawing, and temper mismatches that lead to orange peel or springback. These problems increase scrap rates, slow down forming lines, and create variation in appearance across batches, which is especially costly for architectural and decorative luminaires.

A high quality 3003 aluminum disc for lighting addresses these risks through a balanced combination of alloy chemistry, controlled rolling and annealing practice, and disciplined blanking and inspection. This article explains what overseas buyers should expect from 3003 aluminum circles used for lampshades, reflectors, downlight components, and light housing parts, focusing on material characteristics, forming behavior, and practical temper selection.

Alloy 3003 is an Al-Mn alloy widely used where moderate strength, excellent formability, and good corrosion resistance are required. In lighting, these traits matter because many parts are produced by spinning, deep drawing, or stamping, and must hold a clean surface for painting or anodizing.

Key characteristics relevant to lighting components:

High formability: Suitable for spinning and multi-step deep drawing when the temper is properly selected.

Good corrosion resistance: Helpful for indoor humid environments and some semi-outdoor applications where condensation may occur.

Stable surface quality: When supplied with controlled finish and low residual stress, it supports consistent appearance after anodizing or coating.

Weldability and joining: 3003 is generally weldable and compatible with common mechanical fastening methods used in luminaire assemblies.

For buyers comparing options, 3003 often sits between purer 1xxx alloys (excellent formability but lower strength) and Mg-containing 5xxx alloys (higher strength but different forming and surface behavior). For many luminaires, 3003 provides a practical balance.

A 3003 aluminum disc for lighting is commonly converted into:

Spun or drawn lampshades and decorative covers

Reflectors for downlights and industrial luminaires (often anodized)

Light housings, trim rings, and can components

Shallow drawn caps and covers for retrofit products

Where product lines require more than one alloy family, buyers often review the broader 3000 Series Aluminum circle range for availability and temper flexibility.

Lighting reflectors and shades frequently use metal spinning because it allows smooth curves and low tooling cost. Deep drawing is also common for repeatable geometries. In both processes, the disc must deform uniformly without tearing.

For 3003 aluminum circle used in spinning:

Uniform thickness and low residual stress help reduce chatter marks and waviness.

Controlled grain structure supports a smoother spun surface and reduces the chance of local thinning.

Clean edges (minimal burr) lower the risk of edge cracking at the start of forming.

For 3003 aluminum disc used in deep drawing:

Softer tempers (notably O) generally provide higher drawability.

Work-hardened tempers (such as H14) may be used for shallower draws or parts requiring higher rigidity after forming.

Many lighting components are anodized for appearance and reflectivity, or coated for color and durability. A high quality 3003 aluminum disc for lighting should be evaluated for:

Surface cleanliness: Lower risk of stains, embedded particles, or rolling oil residues that can cause finishing defects.

Finish consistency: A stable rolled finish helps produce uniform anodized tone and gloss.

Forming-related surface defects: Proper temper selection reduces orange peel in curved surfaces after forming.

Because anodizing response depends on many variables (surface preparation, bath chemistry, process control), buyers typically confirm performance through pre-production sampling under their own finishing line conditions.

Temper selection is one of the most frequent sources of quality disputes in cross-border supply. Lighting parts vary widely in draw depth and stiffness requirements, so the same alloy may be supplied in different tempers.

3003-O aluminum disc is annealed to a soft condition. It is commonly used for:

Deep drawn lampshades with higher draw ratios

Multi-pass spinning where large deformation is required

Parts that will be formed extensively before final trimming

Benefits:

Highest ductility and reduced cracking risk

More forgiving for process variation

Trade-offs:

Lower rigidity in the flat state, which may affect handling in automated feeding unless packaging and flatness are well controlled

H1x tempers are strain-hardened (work-hardened) without full annealing. In practice, buyers often specify H14 when they need a balance between formability and stiffness.

Typical scenarios:

Shallow drawn housings or trim components

Spun parts with limited deformation where higher rigidity helps maintain shape

Components where dent resistance matters during assembly

Considerations:

Reduced drawability compared with O temper

Increased sensitivity to edge condition and tooling radius for forming

Higher work-hardened tempers are used less often for heavily formed lighting parts, but may appear in:

Flat or lightly formed discs used as covers

Parts where strength and handling resistance are prioritized

For most spinning and deep drawing operations in lighting, these tempers can increase the probability of cracking unless forming depth is low.

When specifying a 3003 aluminum circle for lampshade or reflector production, buyers commonly align temper with process:

Deep drawing or multi-pass spinning: start with O temper

Moderate forming, need better stiffness: consider H12 or H14

Minimal forming, higher rigidity required: consider H16/H18 if compatible with the process window

For product-specific selection, many buyers standardize around 3003 Aluminum Circle in O or H14 depending on forming depth and appearance requirements.

Quality expectations should be translated into measurable acceptance criteria, especially for overseas procurement where lead times and batch-to-batch consistency are critical.

Lighting reflectors and shades rely on repeatable thickness for consistent forming and reflectivity. Inconsistent thickness can lead to:

Non-uniform wall thickness after drawing

Distortion during spinning

Variation in stiffness and resonance

Buyers typically evaluate thickness consistency through sampling plans and agreed inspection methods.

Residual stress can cause discs to warp after blanking or during forming. Better control supports:

Smooth feeding in press lines

Reduced rework during spinning

Improved appearance after finishing

A cleanly blanked edge improves forming reliability. Poor edge quality increases the risk of edge cracking, especially in harder tempers.

Lighting components are often visible to end users. Surface marks that seem minor on raw metal can become prominent after anodizing or painting. Common buyer focus areas include:

Scratches and handling marks

Roll marks that influence gloss

Oil stains or contamination affecting coating adhesion

The table below lists commonly referenced items for 3003 aluminum disc procurement. Values are not provided here to avoid fabricating parameters that depend on the applicable standard edition, product form, and buyer specification.

| Item | Typical reference in international trade |

|---|---|

| Alloy designation | AA 3003 |

| Product form | Aluminum circle, aluminum disc |

| Temper examples | O, H12, H14, H16, H18 |

| Thickness | 0.5-6.0mm |

| Diameter | 100-1600mm |

| Common standards buyers may cite | EN 573 (chemical composition), EN 485 (sheet strip properties), ASTM B209 (aluminum sheet and plate) |

| Quality management certification (supplier level) | ISO 9001 |

| Surface/finish requirements | As agreed between parties |

| MOQ | 1-3 tons |

For reflectors, 3003 aluminum disc is valued for forming performance and finishing compatibility. Depending on the reflector design, the disc may undergo spinning followed by surface treatment. Consistent surface and controlled forming behavior help maintain reflectivity uniformity.

Decorative shades demand stable forming and a clean appearance. 3003-O is frequently used where deep profiles are required. For simpler profiles or where higher stiffness is needed, 3003-H14 may be considered, provided the forming depth is within capability.

For downlights, track lights, and industrial luminaires, discs may be drawn into housings or trim rings. Here, a balance between formability and post-form rigidity is important, and H12 or H14 is often evaluated alongside O temper.

A high quality 3003 aluminum disc for lighting is primarily a risk-control material choice: it reduces forming defects, stabilizes finishing results, and improves batch consistency for spinning and deep drawing operations. The alloy is widely used because it combines good corrosion resistance with strong processing performance.

For most lighting applications, the key technical decision is temper selection. O temper supports the highest drawability for deep shapes and multi-pass spinning, while H12 and H14 provide additional stiffness for shallower forming and handling robustness. Aligning temper with forming depth, tooling, and finishing requirements is typically the most effective way to achieve reliable production and consistent appearance in aluminum disc for lampshade, reflector, and housing components.

Copyright © 2026 By HAOMEI Aluminum CO., LTD. All Rights Reserved. Sitemap