No.14 Waihuan Road, CBD, Zhengzhou, China

No.14 Waihuan Road, CBD, Zhengzhou, China

+86-18703635966

+86-18703635966

No.14 Waihuan Road, CBD, Zhengzhou, China

No.14 Waihuan Road, CBD, Zhengzhou, China

+86-18703635966

+86-18703635966

International traffic sign programs often face recurring material issues: inconsistent flatness that complicates lamination, surface defects that show through reflective sheeting, edge cracking during forming, and variable stiffness that affects wind-load performance once installed. For overseas buyers managing multiple sign sizes and production batches, these problems translate into rework, lower yield, and disputes between sign shops and material suppliers.

One practical way to reduce these risks is to specify a stable, well-understood substrate material and temper. 1100 H14 aluminum circle is a common choice for aluminum sign blanks and round sign formats because it balances cleanliness, corrosion resistance, and workable strength while remaining friendly to standard fabrication steps.

Traffic sign substrates must support a demanding combination of requirements:

A clean, consistent surface for printing or for bonding reflective film and overlays

Good corrosion resistance in outdoor service, including coastal or high-humidity climates

Predictable forming and machining behavior for blanking, trimming, punching holes, and edge finishing

Sufficient rigidity to remain flat and stable during installation and service

Alloy 1100 belongs to the commercially pure aluminum family (often grouped within the 1xxx series). In traffic sign manufacturing, that high-aluminum chemistry is valued for its excellent corrosion resistance, good thermal and electrical conductivity, and generally smooth surface quality that supports downstream finishing operations.

H14 temper adds controlled strength through strain hardening, which is often preferred over fully soft tempers when the blank must maintain shape and resist handling damage.

Traffic signs are exposed to rain, road spray, UV radiation, and airborne salts. 1100 aluminum disc material is commonly selected in outdoor sheet applications because its corrosion resistance is dependable across diverse environments. This supports longer sign life and reduces the risk of substrate degradation beneath reflective films.

For sign makers, substrate appearance is not only cosmeticit can affect adhesion and final visual uniformity. A consistent surface helps:

Reduce telegraphing of surface defects through reflective film

Improve bonding stability during lamination

Support stable coating behavior when additional finishing is used

Because sign programs often require large batches, buyers typically prioritize repeatability: the same surface behavior across shipments and production lots.

Aluminums low density is an operational advantage for large sign projects. It reduces shipping weight and makes installation easier while maintaining adequate stiffness when specified in appropriate thickness and temper.

Temper selection is a frequent source of confusion in procurement, especially for buyers sourcing from multiple regions. For 1xxx series alloys such as 1100, common tempers in circulation include O, H12, H14, and sometimes H16/H18 depending on supplier capability and required strength.

H14 indicates a strain-hardened temper with a moderate level of cold work. In traffic sign production, H14 is often selected because it:

Provides better rigidity than fully annealed material

Maintains good forming and punching behavior for typical sign fabrication

Resists minor handling dents more effectively than very soft tempers

For many sign shops, H14 supports stable processing while keeping scrap rates under control.

O temper is fully annealed and very soft. It is typically chosen when deep drawing or severe forming is required. For standard traffic sign blankswhere the goal is a flat, stiff panelO temper can be too soft, increasing the risk of:

Dents during transport and handling

Distortion during lamination or mounting

That said, O temper can be useful for specialty sign designs with significant forming.

H12 is less strain-hardened than H14. Buyers may consider H12 when fabrication includes more aggressive forming and they want extra forming margin. H14 is often preferred when stiffness and surface stability are higher priorities.

Harder tempers (where available) increase strength but reduce formability. If the sign blank is expected to undergo bending, flanging, or other forming operations, overly hard material can raise the risk of edge cracking or reduced hole quality.

Procurement tip: temper choice should follow the actual process routeblanking, punching, edge forming, lamination, and mountingrather than being selected purely on strength.

1100 H14 aluminum circles are typically used as round blanks or as feedstock for cutting round blanks. From a fabrication perspective, buyers usually evaluate performance in these areas:

Clean edges and stable geometry are critical for consistent downstream operations. In production, well-made circles should help reduce:

Burr-related rework

Edge damage that can propagate during subsequent forming

Variability in diameter and concentricity that complicates tooling setup

Traffic signs commonly require mounting holes or slots. Material that punches cleanly helps maintain:

Dimensional repeatability

Lower tool wear

Reduced deformation around holes

H14 generally provides a balanced responsestiffer than annealed material, but still workable for standard punching operations.

Reflective film lamination benefits from a stable, flat substrate. Flatness is influenced by multiple factors (material condition, leveling, packaging, and handling). Buyers often specify packaging and handling expectations alongside material grade to reduce transit-induced distortion.

Reflective sheeting performance depends on proper substrate preparation (cleaning, handling, and lamination conditions). While the sign maker controls the process, consistent material surface quality reduces variability and lowers the likelihood of adhesion issues.

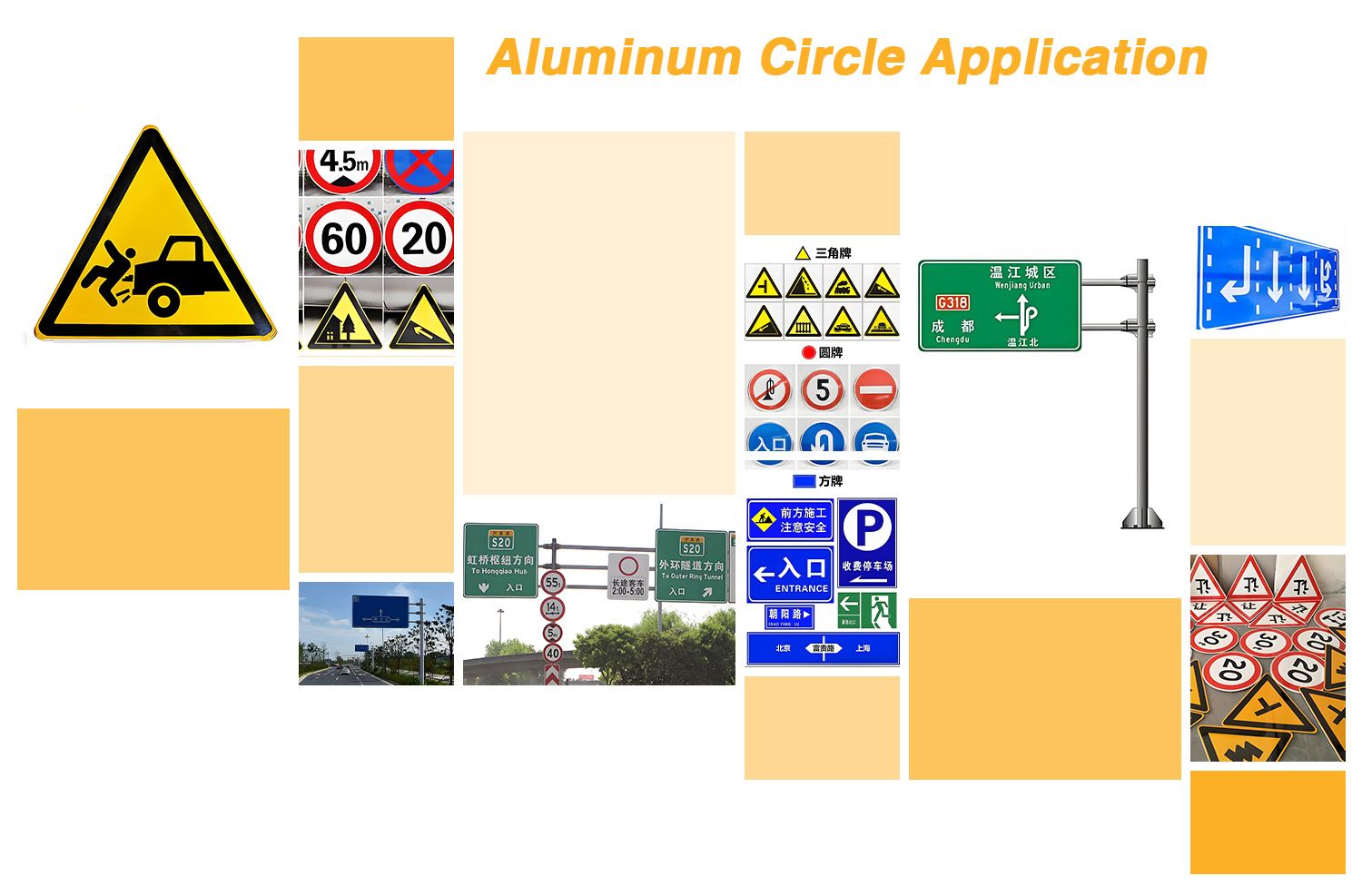

Although traffic sign blanks are available in many shapes, aluminum circles are commonly used for:

Round regulatory and warning signs (where circular formats are required)

Temporary traffic control signs using circular blanks

Custom round identification plates in transport and infrastructure

Round sign components used in assemblies or layered sign designs

In addition to traffic signage, 1100 circles may be used for other applications requiring corrosion resistance and a clean surface, but traffic signs remain a key use case for H14 circles due to the balance of rigidity and processability.

Overseas B2B buyers often manage mixed requirements across regions, contractors, and sign shops. A practical sourcing checklist includes:

Before confirming temper, clarify whether the sign blank will be:

Used as-is (flat blank + film)

Punched with holes/slots

Edge-formed or flanged

Further shaped by bending or rolling

This ensures H14 is suitable, or whether a softer temper is needed.

Surface requirements should reflect the intended finishing method:

Direct lamination with reflective sheeting

Printing and coating workflows

Handling and storage conditions at the sign shop

Clear surface expectations reduce disputes after delivery.

Traffic sign programs may use multiple diameters. Buyers benefit from suppliers who can support stable output across sizes, packaging formats, and shipment schedules.

Even excellent material can arrive damaged if packaging is insufficient. For circles, confirm packaging that limits:

Edge impact damage

Surface abrasion

Moisture exposure in transit

Rather than relying on assumptions, align on how diameter, thickness, flatness, and surface will be checked and documented between buyer and seller. This is especially important for overseas shipments where claims are time-consuming.

If your procurement team is comparing alternatives within commercially pure aluminum, it may be helpful to review other 1xxx series options used in similar fabrication environments. For an overview of available grades and typical positioning, see 1000 Series Aluminum circle.

For buyers who are standardizing on alloy 1100 for multiple projects (not only traffic signage), you can also reference the 1100 Aluminum Circle product page for availability and general supply scope.

Copyright © 2026 By HAOMEI Aluminum CO., LTD. All Rights Reserved. Sitemap