No.14 Waihuan Road, CBD, Zhengzhou, China

No.14 Waihuan Road, CBD, Zhengzhou, China

+86-18703635966

+86-18703635966

No.14 Waihuan Road, CBD, Zhengzhou, China

No.14 Waihuan Road, CBD, Zhengzhou, China

+86-18703635966

+86-18703635966

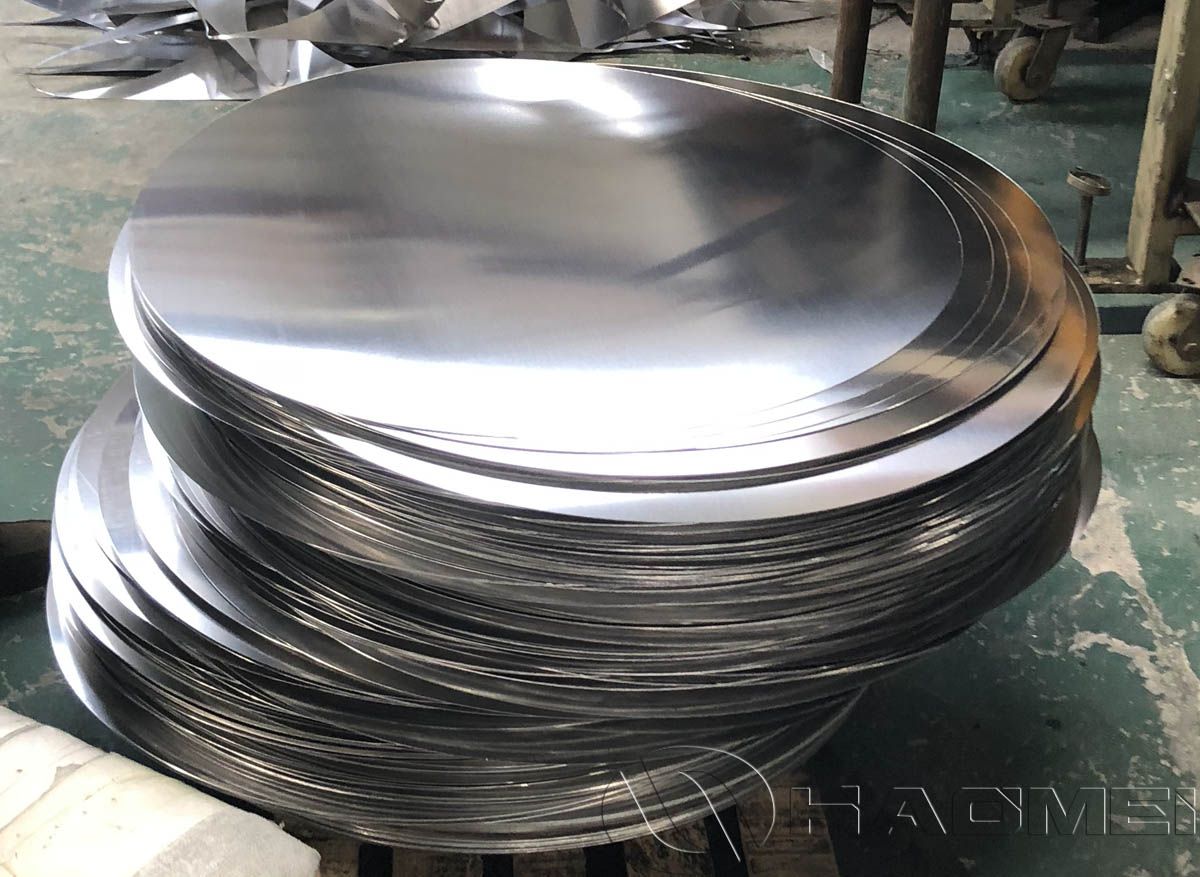

As one of the most representative high-performance materials in the aluminum alloy family, the 6061-T6 aluminum disc is widely recognized for its excellent mechanical properties and broad range of applications. It has become a preferred material in industries such as automotive, aerospace, construction, and mechanical equipment.

6061 aluminum alloy belongs to the Al-Mg-Si heat-treatable alloy series, where the T6 temper indicates solution heat treatment followed by artificial aging. After T6 heat treatment, the alloy achieves significantly improved strength, hardness, and dimensional stability.

| Alloy | 6061 |

| Temper | T6 |

| Diameter | 50 - 1500 mm (customizable) |

| Thickness | 0.5 - 6.0 mm |

| Surface Treatment | Anodizing, brushing, polishing, coating, etc. |

| Applications | Cookware, automotive components, lamp covers, precision molds, etc. |

| MOQ | 1-3 tons |

Mechanical Properties

| Property | 6061-T6 Aluminum Alloy |

| Tensile Strength | 276-310 MPa |

| Yield Strength | 248 MPa |

| Elongation | 12-18% |

| Elastic Modulus | 69 GPa |

| Density | 2.7 g/cm³ |

1. High Strength with Good Toughness

After T6 heat treatment, the material achieves significantly enhanced strength while maintaining sufficient toughness, enabling it to withstand impact loads without brittle failure.

2. Excellent Corrosion Resistance

6061 aluminum alloy inherently offers good corrosion resistance. With appropriate surface treatments such as anodizing, its corrosion resistance can be further improved.

3. Outstanding Machinability

Compared with many high-strength materials, 6061-T6 aluminum alloy provides excellent machinability. Turning, milling, and drilling operations can all achieve high surface quality and dimensional accuracy.

4. Good Weldability

Although welding may locally affect the T6 temper due to heat input, 6061 aluminum alloy overall exhibits good weldability and is suitable for TIG and MIG welding processes.

5. Moderate Thermal and Electrical Conductivity

As an aluminum alloy, 6061-T6 offers balanced thermal conductivity and electrical conductivity, making it suitable for heat dissipation components and certain electrical applications.

6. Excellent Surface Adaptability

6061-T6 aluminum discs can undergo anodizing, polishing, coating, brushing, and other surface treatments to meet both functional and aesthetic requirements.

7. Cost-Effective

Compared with ultra-high-strength alloys such as 7075, 6061 offers lower raw material and processing costs, delivering excellent overall value.

8. Environmentally Friendly and Recyclable

Aluminum alloys are more than 95% recyclable, making 6061-T6 aluminum discs compliant with sustainable development requirements.

Aerospace Industry

Used in aircraft structural components, aerospace parts, and satellite components, where lightweight and high strength are critical.

Automotive Industry

Applied in suspension components, drivetrain parts, and braking system components, balancing performance and weight reduction.

Precision Machinery

Used as base platforms for precision instruments, support structures for optical equipment, and key components in semiconductor manufacturing equipment.

Sports Equipment

Applied in high-end bicycle components, racing parts, and mountaineering equipment, where the balance between strength and weight is essential.

Industrial Equipment

Used for mechanical transmission parts, hydraulic system components, and structural parts of automation equipment, delivering reliable performance in industrial environments.

| Material | Tensile Strength (MPa) | Elongation (%) | Machining Difficulty | Typical Applications |

| 6061-T6 | 276-310 | 12-18 | Medium | Automotive, aerospace, general machinery |

| 6063-T6 | 170-190 | 12-20 | Easy | Architectural decoration, pipe supports |

| 7075-T6 | 503-570 | 8-15 | Difficult | Aerospace high-strength components |

| 5052-H32 | 180-190 | 10-16 | Easy | Food packaging, electronic enclosures |

In summary, 6061 T6 strikes a balance between strength and machinability, making it the most cost-effective high-strength aluminum alloy.

Copyright © 2026 By HAOMEI Aluminum CO., LTD. All Rights Reserved. Sitemap