No.14 Waihuan Road, CBD, Zhengzhou, China

No.14 Waihuan Road, CBD, Zhengzhou, China

+86-18703635966

+86-18703635966

No.14 Waihuan Road, CBD, Zhengzhou, China

No.14 Waihuan Road, CBD, Zhengzhou, China

+86-18703635966

+86-18703635966

Cookware manufacturers and sourcing teams often face the same recurring problems when selecting aluminum discs for non-stick pans: inconsistent deep drawing performance, ear formation that increases trimming loss, surface defects that telegraph through coatings, and variable hardness that causes cracking or springback during stamping.

These issues rarely come from a single cause. They are typically the result of a mismatch between alloy, temper, and processing route, or from insufficient control of surface quality and grain structure for cookware forming.

Against this background, 3003 H24 aluminum disc remains a widely used material option for non-stick pan bodies because it balances formability, moderate strength, and corrosion resistance while supporting stable downstream processing such as blanking, deep drawing, spinning, and coating.

A non-stick pan is not only a formed metal shell. It is a system that includes:

A formed substrate with controlled thickness and geometry.

A prepared surface that must accept primer and non-stick layers.

Service conditions involving heat cycles, moisture, salts, and detergents.

If the disc material is too hard, it can crack during drawing or show excessive springback. If it is too soft or inconsistent, it can distort, scratch easily, or create dimensional variation after forming. If the surface is not controlled, coating adhesion and appearance become harder to manage.

3003 aluminum circle for cookware is often specified when the buyer needs dependable formability and consistent production efficiency for mid-range to high-volume pan lines.

3003 is a 3000 series aluminum-manganese alloy. In general terms, manganese is added to improve strength compared with commercially pure aluminum, while maintaining good ductility and corrosion resistance.

For cookware, this combination matters because the pan body must:

Withstand forming without tearing.

Maintain shape and stiffness during handling and service.

Resist corrosion from kitchen environments.

Formability suited to drawing and spinning: 3003 is commonly selected for drawn cookware bodies and pressed shapes where ductility is essential.

Moderate strength: stronger than 1xxx series options, helping reduce denting while keeping forming practical.

Corrosion resistance: appropriate for typical kitchen exposure; supports longevity of the substrate beneath coatings.

Stable processing window: widely used and recognized across cookware supply chains, which simplifies qualification for overseas buyers.

When buyers specify a 3003 H24 aluminum disc for non-stick pans, they are usually targeting a controlled half-hard condition that supports forming while reducing excessive softness.

Temper is not just a label; it indicates the processing condition of the metal and strongly influences yield strength, elongation, and forming response.

In common industry practice, H24 describes an aluminum product that is strain-hardened and then partially annealed. The intent is to achieve a balance between strength and ductility.

For cookware discs, H24 is often selected when the part geometry needs reliable shaping, but production also benefits from:

Reduced handling damage compared with fully soft material.

More consistent dimensional stability after forming.

Better resistance to minor surface imprinting in high-throughput lines.

Below are typical scenarios where buyers may see these tempers specified for aluminum discs used in cookware. Final selection depends on pan design, draw ratio, press setup, lubrication, and heat treatment steps used by the cookware plant.

Often used when maximum formability is required.

Suitable for deeper drawing or complex shapes.

More prone to handling marks if surface protection is not managed.

Used when higher strength is needed and forming is relatively moderate.

Can be less forgiving in deep drawing compared with O or H24.

Practical balance for many pan bodies.

Often chosen for stable production where both forming and stiffness matter.

Can help reduce excessive softness while still supporting drawing and spinning.

In procurement discussions, it is useful to confirm that the temper and coil-to-disc process are aligned with the cookware plant's forming route. For example, aggressive deep drawing may still require O temper, while shallower shapes may benefit from H14 or H24.

An aluminum disc for non-stick pans is normally produced by blanking from sheet or coil. Edge consistency influences forming, particularly for spinning and drawing operations. Poor edge quality can initiate cracks or produce uneven flow.

Buyers often evaluate:

Burr control and edge cleanliness.

Dimensional consistency of diameter.

Flatness suitable for automated feeding.

For pan bodies, deep drawing and spinning are the primary forming methods. Material with stable ductility helps reduce tearing and wrinkling. While exact outcomes depend on press settings and tooling, 3003 in a suitable temper is commonly used to support:

Controlled metal flow.

Reduced risk of cracking at corners or radii.

Stable wall thickness distribution in typical cookware geometries.

Non-stick systems rely on surface preparation, typically involving cleaning and pretreatment steps defined by the cookware manufacturer and coating supplier. A consistent disc surface helps reduce:

Coating appearance defects caused by scratches or embedded particles.

Variability in surface energy that can affect wetting.

Rework rates during coating inspection.

For overseas buyers, it is important to align surface requirements with the intended finishing route, such as:

PTFE-based non-stick systems.

Ceramic coatings.

Anodized or painted exterior surfaces.

3003 alloy is not heat-treatable in the same way as certain other aluminum families, but it performs reliably under typical cookware operating temperatures when combined with appropriate coating systems and pan design. In production, buyers should consider whether any intermediate thermal steps or curing cycles affect hardness and forming sequence.

While this article focuses on cookware, 3003 discs and circles are widely used where forming and corrosion resistance are required. Typical applications include:

Frying pans and saute pans.

Saucepan bodies and lids.

General formed cookware components.

Reflective or formed items where consistent stamping is needed.

When sourcing across related products, many buyers review broader 3000 series options, such as the 3000 Series Aluminum circle family, to compare forming behavior and strength targets.

Even when the alloy and temper are fixed, several specification details influence production stability.

Key variables that should match the forming process include:

Diameter range and tolerance.

Thickness and allowable variation.

Flatness requirement for feeding and stamping.

For export shipments, surface condition can degrade due to handling, vibration, or moisture. Buyers commonly confirm:

Interleaving paper or film protection.

Clean, dry packing to reduce oxidation and staining.

Palletization suitable for long-distance sea freight.

Overseas buyers typically require consistent documentation tied to lot traceability. The specific certificates provided depend on supplier capabilities and contractual terms, but they should align with recognized material testing and quality management practices.

| Alloy | AA3003,3003 |

| Temper | H24 |

| Standard | ASTM B209 / EN 573 / GB/T 3880 |

| Aluminum Content | ≥ 96.7% |

| Thickness | 0.5 – 6.0 mm |

| Diameter | 100 – 600 mm (customizable) |

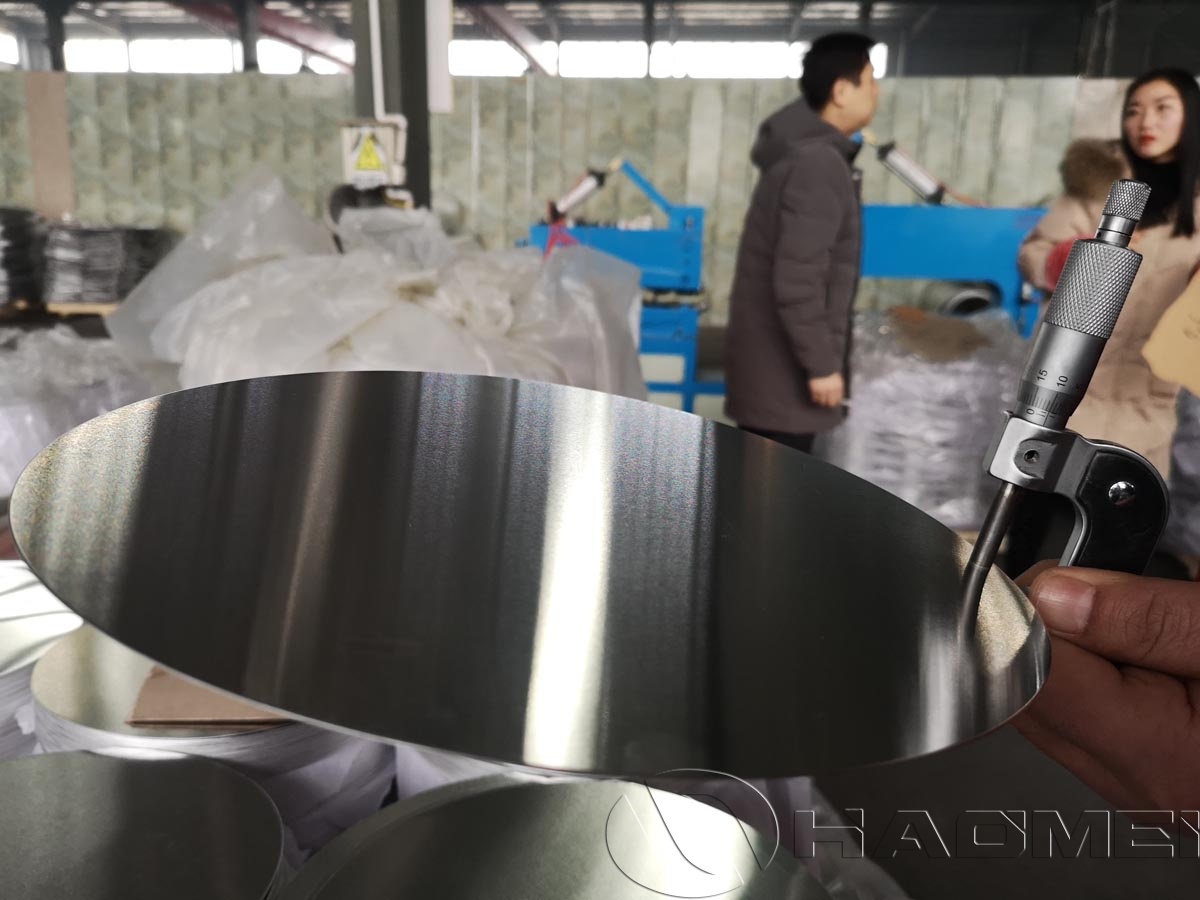

| Thickness Tolerance | ±0.02 mm |

| Diameter Tolerance | ±0.10 mm |

| Surface Finish | Mill Finish / Brushed / Polished |

| Flatness | ≤ 1.5 mm per 1000 mm |

| Edge Condition | Smooth, burr-free |

| Grain Structure | Fine & uniform, suitable for deep drawing |

| Surface Cleanliness | Oil-free, suitable for non-stick coating |

| MOQ | 1-3 tons |

In many supply chains, the term disc and circle are used interchangeably. What matters is that the product is qualified for cookware forming and that it meets diameter, thickness, and surface requirements for the intended pan design.

Buyers who are standardizing cookware substrates across multiple pan sizes often consolidate requirements under a consistent product line such as a 3003 Aluminum Circle to reduce changeovers and qualification complexity.

For non-stick pan manufacturing, repeated production issues often stem from avoidable mismatches between alloy, temper, and forming requirements. A 3003 H24 aluminum disc is commonly selected because it offers a practical balance of formability, moderate strength, and corrosion resistance, while supporting stable blanking, drawing, and spinning performance.

By aligning temper choice (O, H14, H24) with pan geometry and press conditions, and by controlling disc quality factors such as surface condition, edge quality, and dimensional consistency, overseas buyers can reduce scrap risk and improve line stability without over-specifying the material.

Copyright © 2026 By HAOMEI Aluminum CO., LTD. All Rights Reserved. Sitemap