-

-

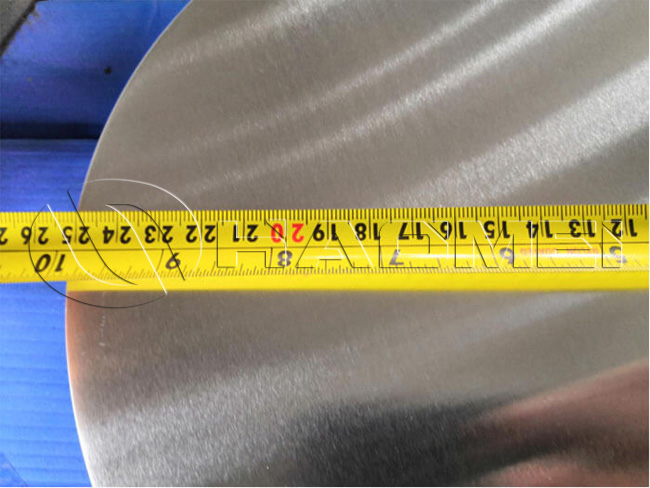

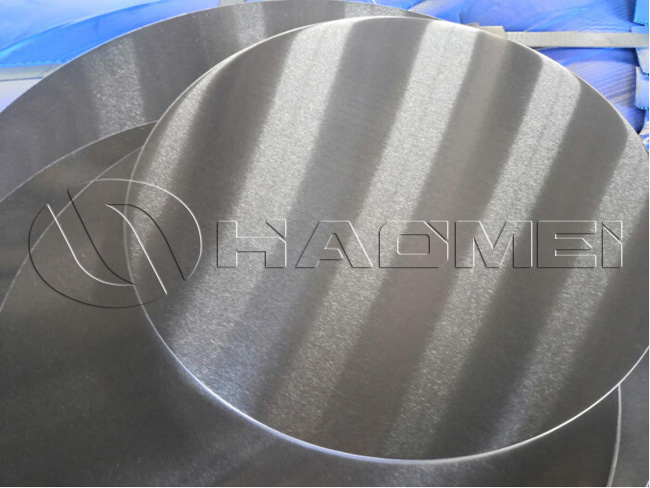

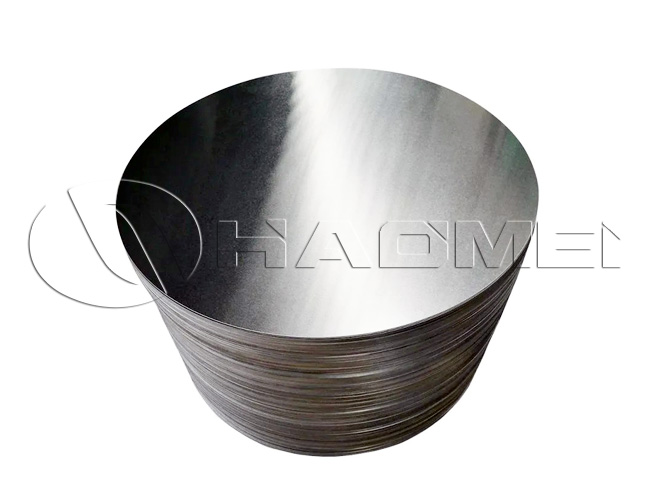

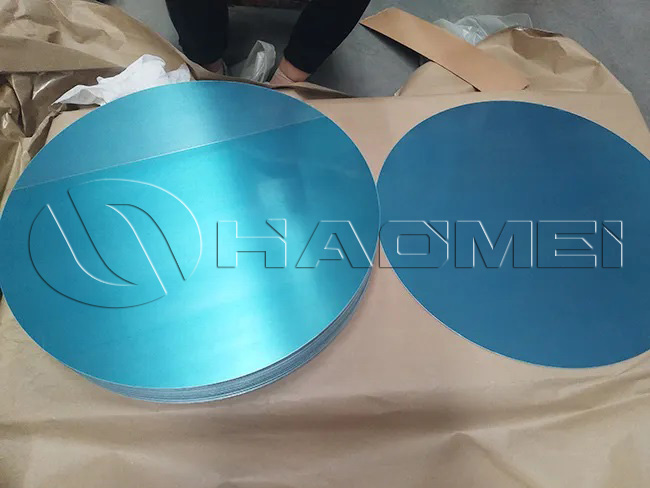

3003 Aluminum Circle

- Alloy 3003

- Tempers H14, H16, H18, H22, H24, H26

- Thickness 0.5-0mm

- Diameter 50-1300mm

- Material DC and CC

- Shapes Round, rectangular, oval, circular

- MOQ 1-3 tons

What is 3003 Aluminum Circle?

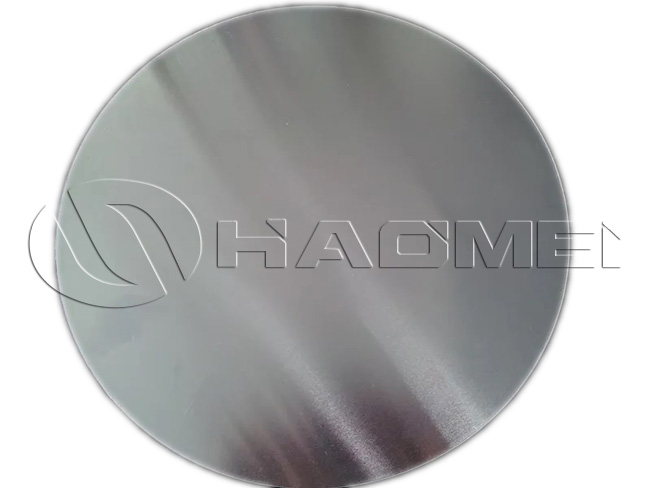

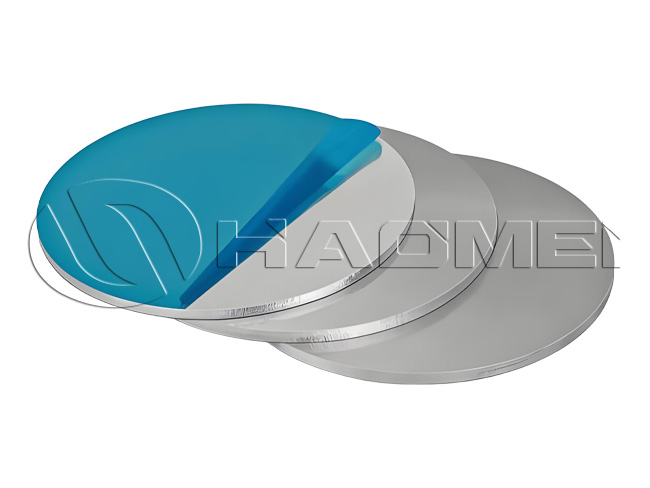

3003 aluminum circle is a round sheet material made from 3003 aluminum-manganese alloy through stamping and cutting processes. It is one of the most widely used and popular anti-rust aluminum materials today.

Because 3003 aluminum circle disc contains manganese, its hardness is much higher than that of 1060 and 1100 aluminum plates. However, its elongation rate is generally not as good as 1060 aluminum. Overall, the hardness of 3003 aluminum circle is about 10% higher than that of 1060 aluminum.

Advantages of AA3003 Aluminum Circle

Higher Strength: The strength of 3003 is about 10%-20% higher than that of 1000 series alloys (such as 1050, 1070, 1200). This allows it to withstand greater pressure and longer service life without easily deforming.

Good Corrosion Resistance: While pure aluminum already offers good corrosion resistance, 3003 performs better in certain environments such as humid and mildly acidic conditions.

Excellent Formability: Although harder than pure aluminum, 3003 still maintains good plasticity, deep drawing ability, and spinning performance, making it suitable for various forming processes.

Good Thermal Conductivity: Although slightly lower than pure aluminum, its heat conductivity is still sufficient for most cookware and industrial applications.

Tempers of 3003 Aluminum Circle

3003 aluminum alloy belongs to the Al-Mn series anti-rust aluminum. It cannot be strengthened by heat treatment; instead, its performance is mainly adjusted through cold working hardening and annealing. Common temper states include:

3003 O Aluminum Circle: Fully annealed, lowest hardness, best ductility and plasticity. Suitable for deep drawing, spinning, cookware, lighting, decorative parts, stamping vessels, etc.

3003 H12 Aluminum Circle: Work-hardened (cold rolled) version with good strength and toughness, suitable for general processing operations.

3003 H14 Aluminum Circle: Higher strength compared with H12. Commonly used in lamp reflectors, signage, household appliance casings, and applications requiring higher strength with moderate hardness.

3003 H16 Aluminum Circle: Similar to H14 but with additional cold working, resulting in higher strength and slightly reduced plasticity. Used for components requiring strength rather than high formability.

3003 H18 Aluminum Circle: Highest strength, lowest elongation. Mainly used for flat sheets, decorative parts, or products with little to no further deep processing.

Product Information

| Alloy | 3003 |

| Alloy Name | AA3003 |

| Tempers | H14, H16, H18, H22, H24, H26 |

| Thickness | 0.5-10 mm |

| Diameter | 50-1300 mm |

| Material | DC and CC |

| Standards | ASTM, EN, DIN, CN |

| Shapes | Round, rectangular, oval, circular |

| MOQ | 1-3 tons |

Mechanical Properties

| Alloy | Temper | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) |

| 3003 | O | 55-75 (8,000-11,000 psi) | 35 (5,000 psi) | ≥25% |

| H12 | 120-160 (17,000-23,000 psi) | 80 (12,000 psi) | ≥6% | |

| H14 | 140-180 (20,000-26,000 psi) | 115 (16,000 psi) | ≥5% | |

| H16 | 170-210 (25,000-30,000 psi) | 145 (21,000 psi) | ≥4% | |

| H18 | ≥195 (≥28,000 psi) | ≥170 (≥25,000 psi) | ≥2% |

Chemical Composition (%)

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Other:Each | Other:Total | Al |

| 3003 | 0.6 | 0.7 | 0.05-0.20 | 1.0-1.5 | - | - | 0.1 | 0.25 | 0.15 | 0.05 | remainder |

Applications of 3003 Aluminum Circle

Cookware & Utensils: Pots, bowls, basins, kettles, teapots, etc. (commonly in O temper for deep drawing).

Lighting Fixtures: Lamp housings, reflectors, etc.

Chemical Containers: Tanks, barrels, and vessels for storing and transporting chemicals and food (taking advantage of corrosion resistance and sealing properties).

Electronics & Appliances: Battery casings (requiring formability, shock resistance, and sealing performance).

Construction & Decoration: Ceilings, decorative parts, nameplates, etc.

Others: Automotive parts (fuel tanks, oil pipes), heat sinks, rivets, etc.

Common Specifications & Selection

Thickness Range: Commonly supplied from 0.3 mm to 6.0 mm (other sizes available upon request).

Production Process

3003 aluminum circle is typically produced using casting-rolling or hot-rolling methods. The 3003 alloy ingot is heated, rolled into aluminum sheets or coils, and then stamped into circular discs of required dimensions with precision punching equipment.

Annealing Process of 3003 Aluminum Circle

Full Annealing: Heating to 390–430 °C; holding for 30–120 min depending on thickness; furnace cooling at 30–50 °C/h to below 300 °C, then air cooling.

Rapid Annealing: Heating to 350–370 °C; holding for 30–120 min depending on thickness; then air cooling or water quenching.

Quenching & Aging: Quenching at 500–510 °C, air cooling; artificial aging at 95–105 °C for 3h, air cooling; natural aging at room temperature for 120 h.

Is 3003 Aluminum Circle Safe for Cookware?

Yes, 3003 aluminum circle is safe for cookware. It is a food-grade material that complies with strict food-contact regulations. In addition, 3003 aluminum alloy does not contain harmful heavy metals. After oxidation or coating, the surface becomes more stable and will not react with acidic or alkaline foods, ensuring that your dishes are both safe and delicious.

However, to guarantee the safety and longevity of aluminum cookware, it is essential to follow the manufacturer’s usage and maintenance instructions.

No.14 Waihuan Road, CBD, Zhengzhou, China

No.14 Waihuan Road, CBD, Zhengzhou, China +86-18703635966

+86-18703635966

+86-18703635966

+86-18703635966

sales@alummc.com

sales@alummc.com

8618703635966

8618703635966