-

-

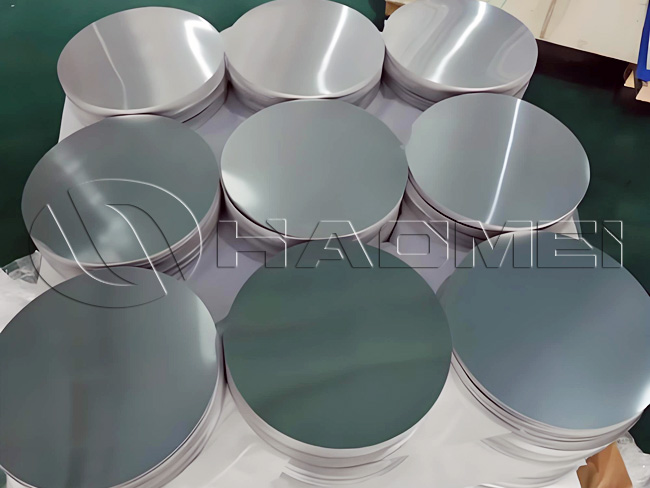

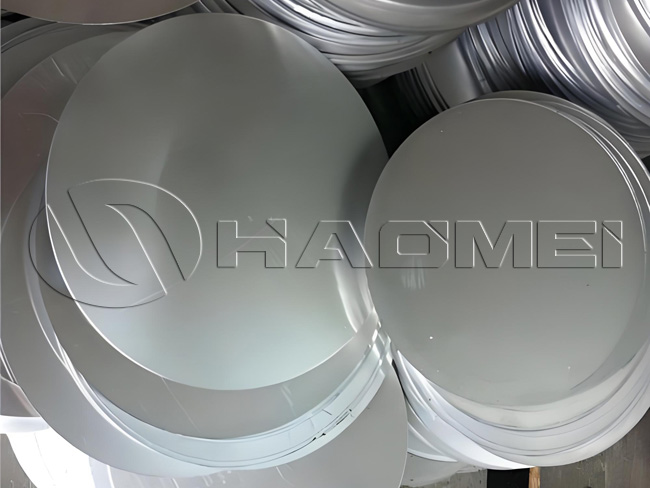

5754 Aluminum Circle Discs

- Alloy 5754

- Temper O, H12, H14, H16, H18, H22, H24, H26, H32, H34, H36, H38

- Diameter 100-2000 mm

- Thickness 0.5-6.0 mm

- Surface Treatment Mill finish, polished, anodized, coated

- MOQ 1-3 tons

What is a 5754 Aluminum Circle Disc?

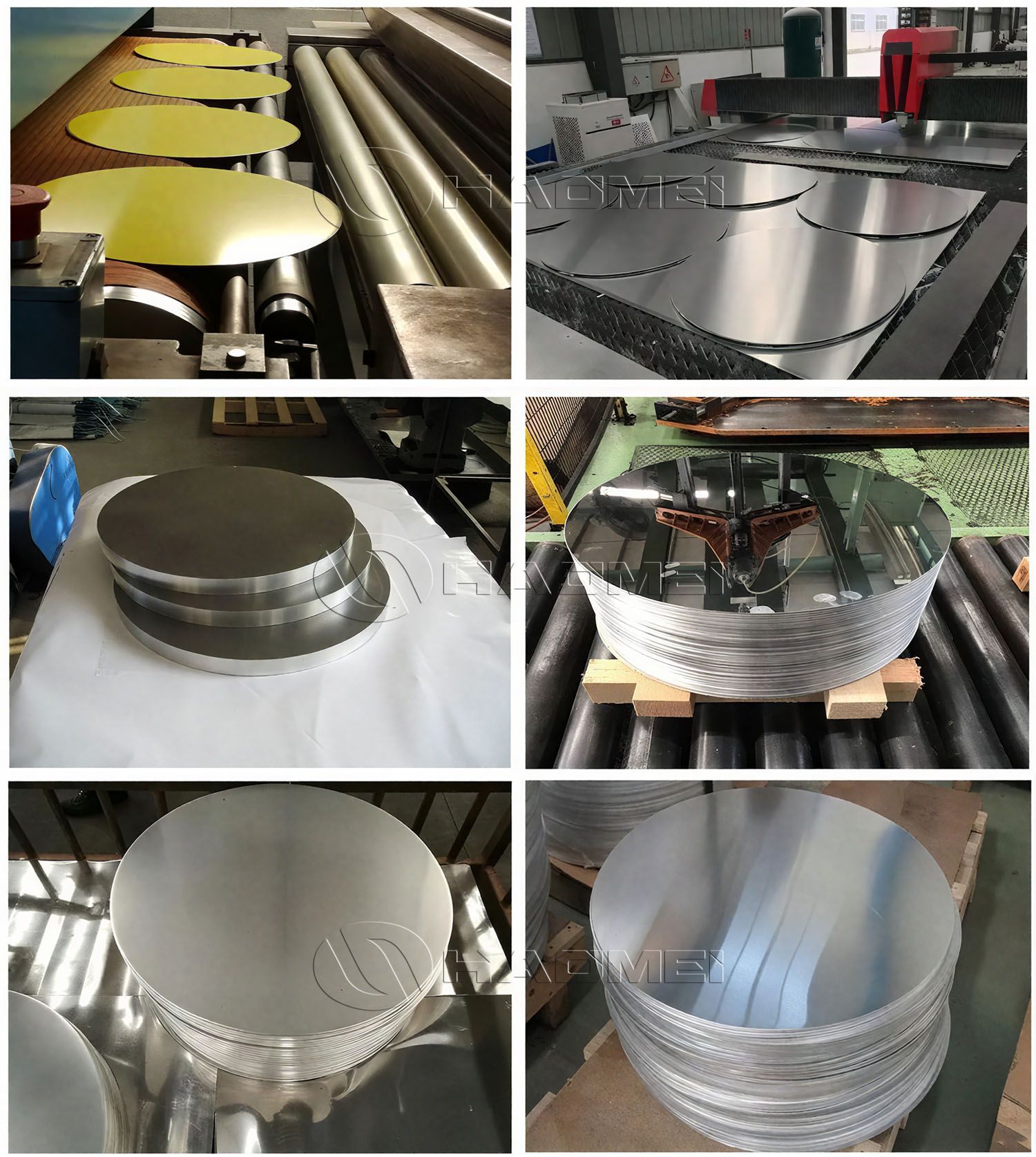

A 5754 aluminum circle disc, also commonly referred to as a 5754 aluminum circle, is a round-shaped product cut from 5754 aluminum alloy sheets.

5754 aluminum alloy belongs to the aluminum-magnesium family (5xxx series) and is one of the representative grades of anti-rust aluminum. As an outstanding medium-strength alloy, it inherits the excellent corrosion resistance and good formability of the 5xxx series while also offering great strength and welding performance, making it widely used across various industries.

Properties of 5754 Aluminum Discs

Excellent corrosion resistance: Particularly resistant to seawater and marine atmospheric environments, making it ideal for ships, offshore facilities, and outdoor humid conditions.

Good weldability: Low tendency for welding cracks; weld joints and base metal retain high strength, suitable for welded structures.

Excellent formability: Easy to perform bending, stretching, and deep drawing operations.

Medium strength: Higher strength than pure aluminum and 3003 alloy, but lower than high-strength alloys like 6061. It cannot be strengthened by heat treatment; instead, its strength is obtained through cold working (e.g., H32, H34 temper).

High fatigue strength: Performs well under repeated loads and vibrations.

Specifications of 5754 Aluminum Wafers

| Alloy | 5754 |

| Temper | O, H12, H14, H16, H18, H22, H24, H26, H32, H34, H36, H38 |

| Diameter Range | 100 mm - 1200 mm |

| Thickness Range | 0.5 mm - 6.0 mm |

| Surface Treatment | Mill finish, polished, anodized, coated |

| Standards | ASTM B209, EN 485 |

| Certificates | ISO 9001:2015, SGS |

| MOQ | 1-3 tons |

5754 Aluminum Wafer Chemical Composition (%)

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Al |

| 5754 | ≤0.40 | ≤0.40 | ≤0.10 | 2.6-3.6 | ≤0.50 | ≤0.30 | ≤0.20 | ≤0.15 | Remainder |

Mechanical Properties of 5754 Aluminum Alloy

| Temper | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) |

| O | 190 | 80 | 16-18 |

| H32 | 230 | 130 | 10 |

| H34 | 260 | 160 | 7 |

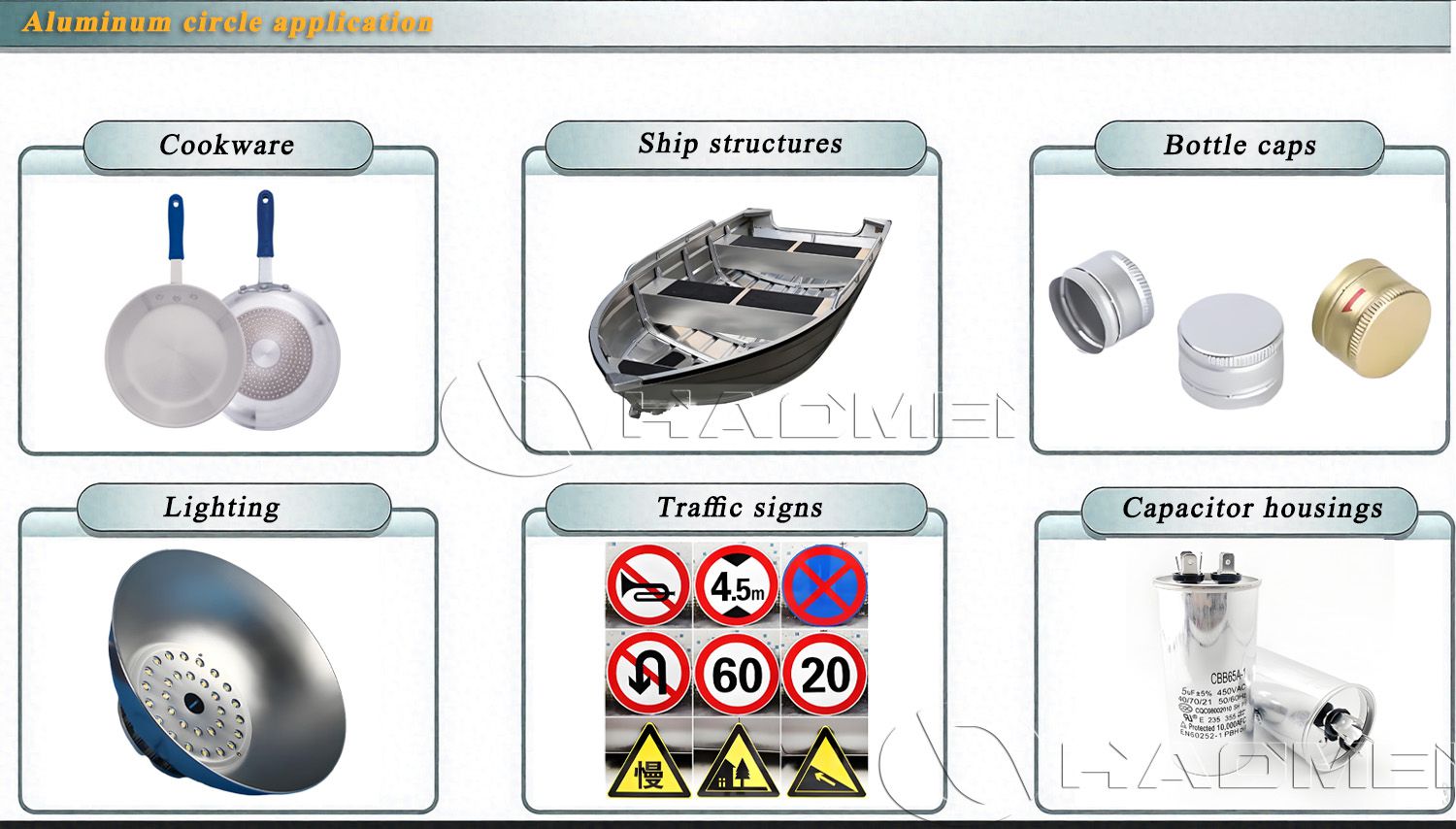

Common Applications of 5754 Aluminum Circle

5754 aluminum round blanks, as semi-finished materials, are mainly used for further processing. Typical applications include:

Automotive industry: Car doors, molds, seals, fuel tanks, and other stamped parts.

Shipbuilding and marine engineering: Ship structures, offshore facility components, fishing equipment.

Pressure vessels and storage tanks: Welded tanks, pressure vessels, transportation tankers (e.g., oil tanker bodies).

General manufacturing: Enclosures, cabinets, battery covers, and other parts requiring strength and good formability.

Cookware and kitchenware: High-quality non-stick pans, pressure cookers, rice cooker inner pots, and other high-performance cookware.

5754 Aluminum Discs vs 5052 Aluminum Discs

Both 5754 and 5052 belong to the 5xxx series aluminum-magnesium alloys, known for good corrosion resistance and formability. However, there are key differences:

Strength & Hardness: The magnesium content in 5754 (2.6%-3.6%) is higher than in 5052 (2.2%-2.8%), giving 5754 greater strength and hardness. This makes it better suited for structural parts that must withstand higher loads and stress, such as automotive bodies and pressure vessels.

Formability: While 5052 is slightly lower in strength, it offers superior deep drawing and forming properties, making it more suitable for cookware, electronic casings, and other products requiring complex shapes.

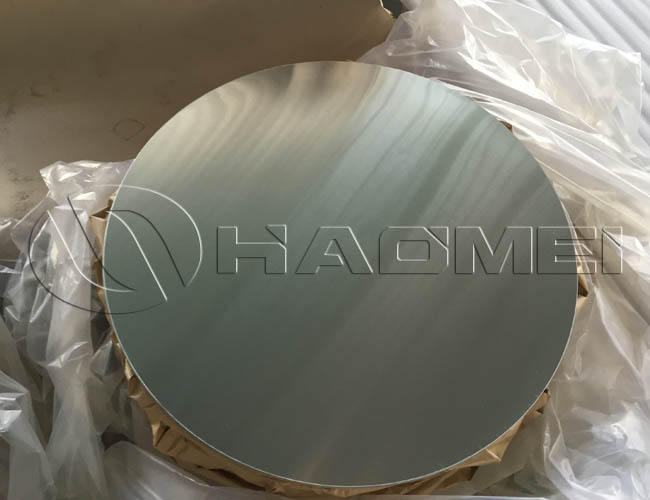

Surface Quality Requirements of 5754 Aluminum Circle Discs

Surfaces must be free from cracks, corrosion spots, and nitrate traces.

Minor surface defects (such as peeling, bubbles, local mechanical damage) are allowed but must not exceed 8% of the nominal thickness, with maximum depth not exceeding 0.5 mm, and total defective area not exceeding 5% of the surface.

For applications requiring surface treatments such as anodizing, stricter surface quality standards are necessary.

How to Choose the Right 5754 Aluminum Circle?

1. Define the application and requirements: Consider the final use, mechanical properties needed (strength, elongation), processing methods (deep drawing, shallow drawing, cutting), and whether surface treatment is required. This determines the temper (O, H32, etc.) and surface quality grade.

2. Size precision: Clearly specify thickness and diameter tolerances to the supplier.

3. Supplier qualification: Select reputable suppliers with stable quality. If necessary, request Material Test Certificates (MTC) or inspection reports.

No.14 Waihuan Road, CBD, Zhengzhou, China

No.14 Waihuan Road, CBD, Zhengzhou, China +86-18703635966

+86-18703635966

+86-18703635966

+86-18703635966

sales@alummc.com

sales@alummc.com

8618703635966

8618703635966