-

-

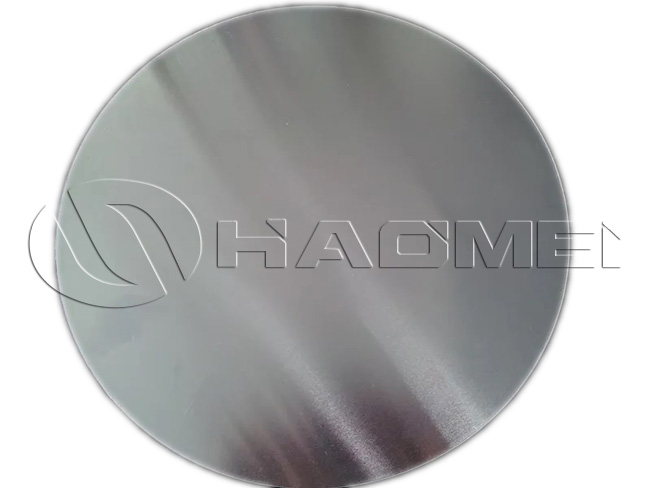

8011 Aluminum Circle

- Name CC8011 / DC8011 / 8011

- Temper O, H12, H14, H18, H22, H24

- Thickness 0.4 - 6.0 mm

- Diameter 100 - 1200 mm

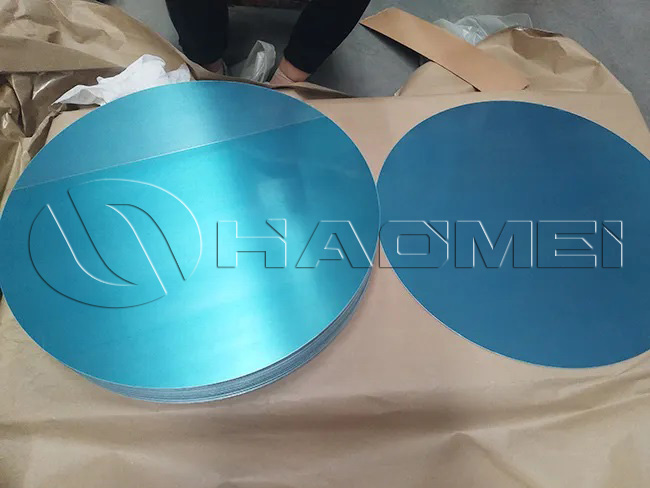

- Surface treatment Mill finish, coated, anodized, brushed, etc.

- Surface quality Bright and clean, free from scratches, stains, or black lines

- Applications Cookware, utensils, pots, pans, lamps, LED housings, traffic signs, etc.

- MOQ 1-3 tons

8011 Aluminum Circle

HAOMEI Aluminum is a professional supplier of aluminum discs, with a monthly production capacity of 2,000 tons. The company owns 7 fully automated production lines and mainly produces aluminum discs from the 1xxx, 3xxx, 4xxx, 5xxx, and 8xxx series.

What is 8011 Aluminum Circle Disc?

8011 aluminum alloy belongs to the 8xxx series, with aluminum (Al), iron (Fe), and silicon (Si) as its main elements. It exhibits excellent corrosion resistance, thermal conductivity, and deep drawing performance. It contains no harmful substances such as lead or mercury and meets food-grade safety standards, making it widely used in multiple industries.

Common Tempers

The temper of aluminum determines its hardness and processing performance. The most common tempers of 8011 aluminum circle discs are:

O temper (annealed): Fully annealed, very soft, with excellent ductility. Suitable for deep drawing and forming (e.g., cookware, cups).

H14 / H24 temper (semi-hard): Higher strength than O temper with moderate hardness while maintaining good processability. H14 is strain-hardened and partially annealed, while H24 is strain-hardened and then partially annealed. Both are often used in lids and containers where strength is required.

Manufacturing Process of 8011 Aluminum Discs

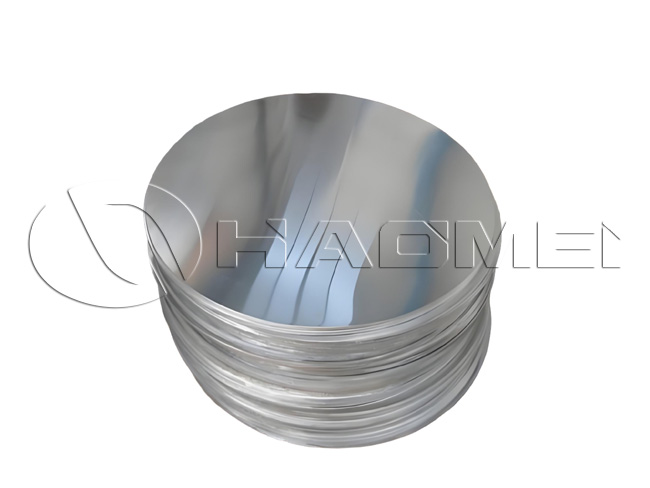

8011 aluminum circle discs are usually manufactured using continuous casting and rolling technology. First, electrolytic aluminum and solid materials are melted into aluminum alloy liquid, which is refined three times. The melt is then cast into a continuous casting slab through a caster and rolled into coil sheets through a rolling mill. After cold rolling and annealing, the coils are finally stamped or cut into circular discs. Automated production lines ensure high efficiency and product quality.

Aluminum Wafer Product Information

| Name | CC8011 / DC8011 / 8011 |

| Temper | O, H12, H14, H18, H22, H24 |

| Thickness range | 0.4 mm - 6.0 mm |

| Diameter range | 100 mm - 1200 mm |

| Surface treatment | Mill finish, coated, anodized, brushed, etc. |

| Edge condition | Smooth edges, burr-free |

| Surface quality | Bright and clean, free from scratches, stains, or black lines |

| Applications | Cookware, utensils, pots, pans, lamps, LED housings, traffic signs, etc. |

| Packaging | Wooden pallets |

| MOQ | 1 - 3 tons |

Chemical Composition (%)

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Other:Each | Other:Total | Al |

| 5083 | 0.50-0.90 | 0.6-1.0 | 0.1 | 0.2 | 0.05 | 0.05 | 0.1 | 0.08 | 0.05 | 0.15 | Remainder |

Mechanical Properties

| Tensile Strength | 95-125 MPa |

| Yield Strength | ≥ 80 MPa |

| Elongation | ≥ 2% |

| Brinell Hardness | HB 28-44 |

| Density | 2.71 g/cm³ |

| Electrical Conductivity | 38% IACS |

| Thermal Conductivity | 237 W/m·K |

| Melting Point | 640-660°C |

Advantages of 8011 Aluminum Discs

Excellent corrosion resistance: The alloy composition and dense oxide film provide strong resistance to rust, especially in humid environments.

Good formability: Can be stamped, stretched, and deep-drawn at room temperature without cracking, making it easy to form into various shapes.

Moderate strength: Higher strength than pure aluminum (1xxx series) but lower than 3xxx (Al-Mn) and 5xxx (Al-Mg) alloys.

Hygienic and safe: Non-toxic and odorless, compliant with food and pharmaceutical packaging standards.

Good thermal conductivity and sealing performance: Suitable for applications requiring heat transfer and sealing.

Cost-effective: Relatively low price, making it an ideal choice for many consumer and industrial products.

Lightweight yet strong: Aluminum’s light weight combined with the appropriate strength of 8011 alloy results in durable and easy-to-handle products.

8011 Aluminum Disc Applications

Cookware & kitchenware: The largest application field, used in manufacturing aluminum pots, basins, kettles, frying pans, steamers, cake molds, etc.

Food & pharmaceutical packaging: Pull-tab can lids, yogurt lids, medicine bottle caps, yogurt cups, etc.

Electronics industry: Used as shielding covers, housings, and certain components.

Lighting industry: Reflectors, lamp holders, and lighting cups.

Home appliances: Components for various appliances.

Other industrial uses: Signboards, nameplates, promotional gifts, etc.

![1756864099779150.jpg 8011-aluminum-circle-application].jpg](/uploads/image/20250903/1756864099779150.jpg)

More Aluminum Circle Disc Products

| Series | Temper | Alloy | Features | End Use |

| 1xxx | O, H2, H4, H*6, H18, H111, H112 | 1050, 1060, 1070, 1100, 1200 | 1. Aluminum content >99%, excellent formability 2. High reflectivity 3. Stable anodizing surface 4. Low cost | 1. General cookware: polishing, sandblasting, pressed lids, aluminum pots 2. Lighting parts: downlights, panel lights, streetlight reflectors 3. Signs & construction: traffic signs, curtain walls, ceilings |

| 3xxx/4xxx | 3003, 3004, 3005, 3105, 4006 | 1. Excellent formability 2. High elongation, suitable for deep drawing 3. Fine grain, smooth surface, high reflectivity | 1. Premium cookware: anodizing, enamel coating, spraying, deep drawing; non-stick pans, pressure cookers 2. Lighting parts 3. Signs & construction | |

| 5xxx | 5052, 5754, 5083 | 1. Low density, lightweight 2. High tensile strength, elongation, and fatigue strength 3. Higher grain grade, better surface finish | 1. Premium cookware: anodizing, enamel coating, spraying, deep drawing; non-stick pans, pressure cookers 2. Pressure vessels: high-pressure cookers | |

| 8xxx | 8011 | 1. Excellent anodizing effect 2. Stable performance, high surface quality | Premium cookware: pearl-anodized cookware |

No.14 Waihuan Road, CBD, Zhengzhou, China

No.14 Waihuan Road, CBD, Zhengzhou, China +86-18703635966

+86-18703635966

+86-18703635966

+86-18703635966

sales@alummc.com

sales@alummc.com

8618703635966

8618703635966