No.14 Waihuan Road, CBD, Zhengzhou, China

No.14 Waihuan Road, CBD, Zhengzhou, China

+86-18703635966

+86-18703635966

No.14 Waihuan Road, CBD, Zhengzhou, China

No.14 Waihuan Road, CBD, Zhengzhou, China

+86-18703635966

+86-18703635966

Non-stick pan manufacturers and cookware buyers often face the same production challenges: uneven heat distribution leading to hot spots, inconsistent forming results such as earing or cracking during deep drawing, and surface defects that reduce coating adhesion or show through after finishing. These issues typically trace back to the base materialits purity level, grain structure, temper selection, and how well the aluminum circle tolerates forming and surface preparation.

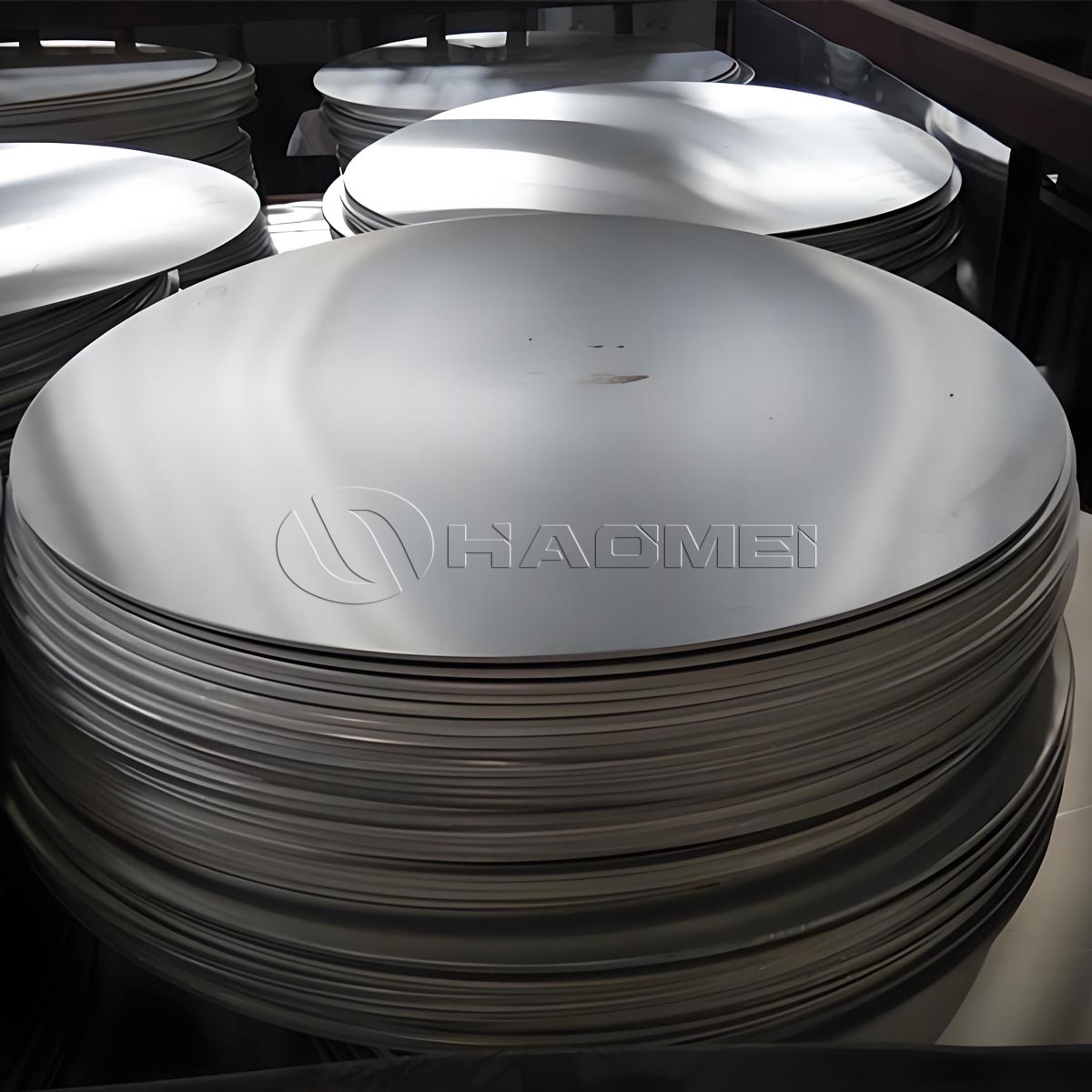

For cookware plants serving export markets, material consistency matters as much as cost. A stable supply of aluminum circles with predictable drawability, clean surface, and reliable flatness can reduce scrap rates, shorten die-debug cycles, and improve coating yield. In this context, 1000 series aluminum circle is widely used for non-stick pans due to its high aluminum content, good thermal conductivity, and excellent forming performance.

The 1000 series refers to commercially pure aluminum alloys (commonly above 99% Al). In cookware, this translates into a combination of practical benefits:

Heat transfer efficiency: Pure aluminum has high thermal conductivity, supporting fast and more even heat distribution in pan bodies.

Formability: Compared with many alloyed grades, 1000 series material generally offers better ductility, which is critical for deep drawing and spinning.

Surface suitability: A clean, low-impurity surface reduces the risk of coating defects and improves consistency after mechanical or chemical pretreatment.

Low density: Supports lightweight cookware designs without sacrificing base thickness where forming requires it.

For overseas buyers, the key is matching alloy and temper to the forming route (deep drawing, spinning, stamping) and downstream finishing (PTFE/non-stick coating, anodizing, brushed finishes).

Cookware circles within the 1000 series are typically specified as 1050, 1060, 1070, or 1100, depending on the target balance between purity, forming behavior, and cost structure.

1050 is a widely traded grade for cookware because it combines high purity with stable processing performance. It is often selected when manufacturers require consistent drawability and an economical supply chain.

1060 provides slightly higher aluminum content than 1050, and it is commonly used where improved ductility and surface cleanliness are prioritiesespecially for deeper draws or more demanding surface appearance.

When evaluating an aluminum circle for non-stick pans, buyers typically focus on properties that affect forming, thermal behavior, and coating consistency.

Non-stick pans rely on predictable heat distribution to avoid localized overheating that can degrade coating performance. High-purity aluminum supports rapid heat spreading across the base, improving temperature uniformity.

Deep-drawn cookware bodies require stable ductility. Inconsistent grain size or texture can cause earing, uneven wall thickness, and trimming losses. For 1000 series circles, consistent rolling and annealing practice is essential to control texture and improve drawability.

Non-stick coating systems depend on surface preparation. A clean, defect-minimized surface helps reduce pinholes, fisheyes, and local delamination risk after curing. Circles intended for cookware are often specified with requirements for:

Low surface scratches and roll marks

Minimal oxide inclusions or embedded particles

Consistent finish suitable for pretreatment and spray/roller coating

Aluminum is naturally corrosion-resistant due to its oxide layer. In cookware manufacturing, compatibility is mainly driven by the chosen coating system and pretreatment chemistry; base metal cleanliness and uniformity are important for consistent results.

1000 series aluminum circles are commonly processed through several forming and finishing steps. Their performance in each step affects yield and product appearance.

Good blanking quality and flatness reduce downstream forming instability. Flatness becomes more critical as diameters increase or when automated feeding systems are used.

Deep drawing is common for non-stick pans, saucepans, and certain wok designs. 1000 series alloys are typically favored for their ductility, which supports:

Higher draw ratios (subject to design and lubrication)

Lower risk of cracking at the wall-to-base transition

Better wall thickness distribution compared with less ductile materials

For spun cookware bodies, consistent softness and surface condition support smoother metal flow, reducing wrinkling and minimizing surface tearing.

While many non-stick pans use organic coatings rather than anodizing, some cookware components or premium series may combine anodized surfaces with non-stick layers. High-purity aluminum is generally suitable for uniform surface response, provided pretreatment is controlled.

Temper selection is one of the most practical levers for cookware plants. For 1000 series aluminum circles, common tempers include O (annealed), H12, H14, and sometimes H16, depending on forming severity and stiffness requirements.

Best for: deep drawing, spinning, and complex forming.

O temper offers the highest ductility and is commonly chosen for non-stick pan bodies that require significant deformation. It helps reduce cracking risk and supports smoother metal flow in dies.

Best for: shallow drawing, stamping, pan lids, and parts requiring more rigidity.

H12 is lightly work-hardened and provides a balance between formability and strength.

H14 is more work-hardened than H12, offering higher stiffness but reduced deep-draw margin.

These tempers can be practical when the part geometry is simpler or when manufacturers want improved shape retention and reduced distortion during handling.

Deep-drawn non-stick frying pans: typically favor O temper to maximize drawability.

Shallow pressed items or flat cookware components: may use H12/H14 to improve rigidity.

Automation and stacking-sensitive lines: sometimes prefer slightly harder tempers for handling robustness, provided forming requirements remain within limits.

1000 series circles are commonly used in:

Non-stick frying pans (pressed or deep-drawn bodies)

Saucepans and small pots (drawn bodies with coated interiors)

Wok-style cookware (often spun, sometimes combined with additional base structures)

Cookware lids and accessories (shallower forming, often harder tempers)

The combination of thermal performance and formability makes cookware aluminum disc stock in 1050/1060 especially common for mass production lines.

The exact parameters for aluminum circles vary by supplier capability, production route, and buyer specification. The table below lists verifiable, non-fabricated reference items that overseas buyers typically include in RFQs and purchase specifications.

| Category | What buyers specify | Notes (no numeric fabrication) |

|---|---|---|

| Alloy | 1050 / 1060 / 1070 / 1100 | Common 1000 series choices for cookware circles |

| Temper | O, H12, H14 (sometimes H16) | Selected based on draw depth, stiffness, and process route |

| Forming route | Deep drawing, spinning, stamping | Drives temper selection and surface requirements |

| Surface quality | Clean surface, low scratch, suitable for coating | Requirements vary by coating line sensitivity |

| Inspection items | Thickness consistency, flatness, edge quality | Often tied to feeding stability and forming yield |

| Compliance / documentation | Mill test certificate, lot traceability | Content and format depend on buyer and destination market |

| Standards | As specified by contract/order | Buyers typically state the applicable standard or equivalent in the PO |

For cookware exporters, coating lines and forming dies are sensitive to lot-to-lot changes. A stable supply of 1000 series circles with repeatable temper and surface condition reduces adjustment time and scrap.

Non-stick coating performance can be impacted by edge burrs, particles, and surface defects. Clear agreement on acceptable surface condition and edge quality helps prevent disputes after arrival.

A deeper draw does not simply require soft material; it requires the correct combination of ductility, controlled texture, and consistent thickness. For many pan designs, 1050 aluminum circle or 1060 aluminium circle in O temper is a typical starting point for qualification, while H12/H14 may fit simpler geometries.

Production problems in non-stick pan manufacturingsuch as inconsistent drawing results, coating defects, and heat distribution issuesare frequently linked to the base metal. 1000 series aluminum circle is widely used for non-stick pans because it offers high thermal conductivity, strong forming capability, and a surface suitable for coating preparation. By selecting an appropriate alloy (commonly 1050 or 1060) and matching temper (O for deep drawing; H12/H14 for less severe forming), overseas buyers can align material performance with manufacturing requirements and finished cookware expectations.

Copyright © 2026 By HAOMEI Aluminum CO., LTD. All Rights Reserved. Sitemap