-

-

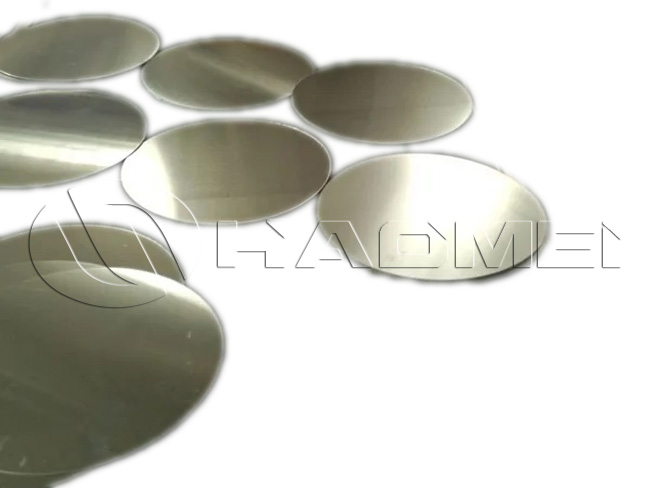

5052 Aluminum Circle

- Alloy 5052

- Temper O, H32, H34, H111

- Thickness 0.5-6.0mm

- Diameter 100-1600mm

- Surface Bright, matte, brushed, anodized, etc.

- MOQ 1-3 tons

Overview

The 5052 aluminum circle disc is made from 5052 aluminum alloy, processed into precise circular discs with smooth surfaces. Common temper states include O (annealed, softest) and H32 (half-hard). These discs are produced through rolling, cutting, or stamping, forming circular aluminum sheet products. As a typical member of the 5xxx aluminum (Al-Mg) family, 5052 aluminum circles offer excellent mechanical properties, corrosion resistance, and workability, widely used in industrial manufacturing and consumer products.

Due to their smooth surface, high quality, good elongation, and uniform anodized finish, 5052 aluminum circles are widely used in pressure cookers, cookware, and lighting products. This explains their broad application in daily life.

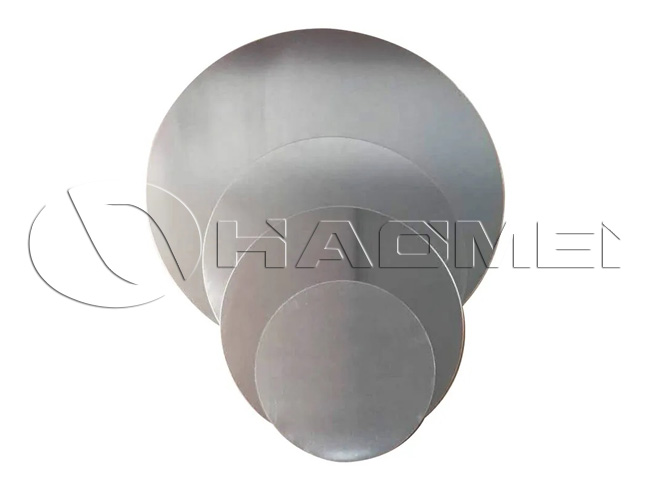

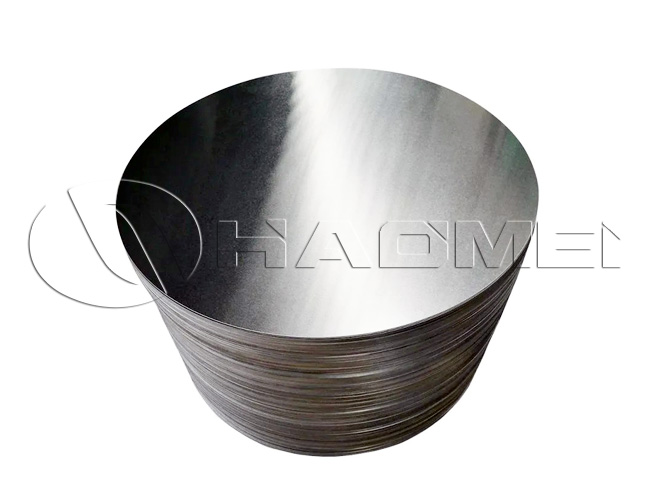

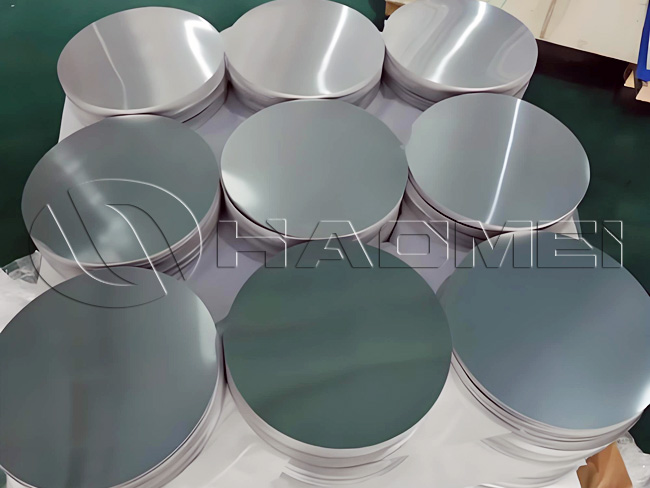

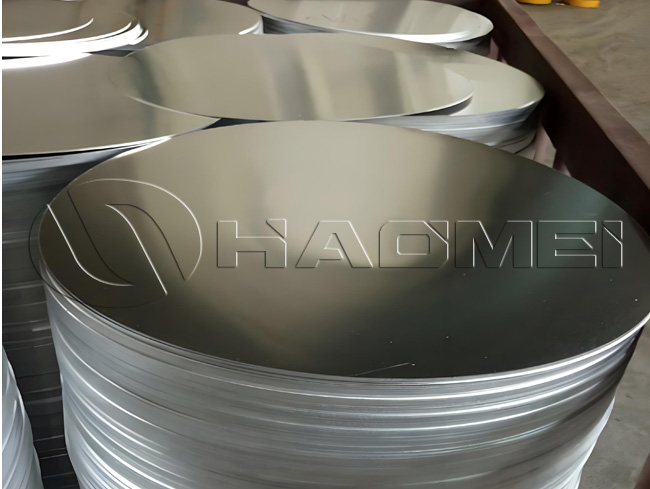

HAOMEI Aluminum manufactures aluminum circle discs in a wide range of sizes, with thickness from fractions of a millimeter up to several millimeters and diameters from a few millimeters to several hundred millimeters, including aluminum circles, aluminum discs, CC aluminum circles, DC aluminum circles, and non-stick aluminum circles.

Product Specifications

| Alloy | 5052 |

| Temper | O, H32, H34, H111 |

| Thickness | 0.5mm - 6.0mm |

| Diameter | 100mm - 1200mm |

| Surface | Bright, matte, brushed, anodized, etc. |

| Equivalent grades | European standard: AW-AlMg2.5 Indian standard: 5251 USA (AA): 5052 ISO: AlMg2.5 China standard: 5052 |

| Samples | Available |

| MOQ | 1-3 tons |

Chemical Composition (%)

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Ni | Zn | Ti | Zr | Al |

| 5052 | 0.25 | 0.4 | 0.4 | 0.1 | 2.2-2.8 | 0.15-0.35 | - | 0.1 | - | - | Remainder |

Features and Advantages

Excellent corrosion resistance: Especially against seawater and marine atmospheres, making it ideal for outdoor and humid environments.

High fatigue strength: Durable under repeated stress or vibration, less prone to cracking.

Good formability: Suitable for bending, stretching, deep drawing, and other cold working operations, allowing complex shapes.

Moderate strength: Stronger than pure aluminum (1xxx series) and 3003 aluminum but lower than 6xxx (e.g., 6061) or 7xxx high-strength alloys. Cannot be strengthened by heat treatment, only by cold working.

Good weldability: Achieves strong welds using conventional welding methods.

Excellent surface treatment performance: Can be anodized, painted, brushed, polished, etc., for attractive and durable surfaces.

Why 5052 O Aluminum Circle is Marine Grade

Due to its superior corrosion resistance and excellent weldability, many customers use 5052 alloy in shipbuilding, small boat construction, oil tankers, storage tanks, and marine facilities.

Application areas of aluminum wafters 5052

Shipbuilding: Hulls, structural components

Automotive industry: Fuel tanks, sheet metal parts, luggage racks

Electronics: Housings for phones, cameras, and other devices

Architectural decoration: Ceilings, curtain walls, signboards

Chemical industry: Storage tanks, pipelines

Daily use: Lighting fixtures, cookware, appliance panels

HAOMEI Aluminum is an experienced exporter of aluminum circles, producing 1000, 3000, 4000, 5000, and 8000 series with complete specifications, customizable sizes, high output, fast delivery, and export to over 40 countries. They are highly trusted by clients and provide comprehensive after-sales service.

No.14 Waihuan Road, CBD, Zhengzhou, China

No.14 Waihuan Road, CBD, Zhengzhou, China +86-18703635966

+86-18703635966

+86-18703635966

+86-18703635966

sales@alummc.com

sales@alummc.com

8618703635966

8618703635966