No.14 Waihuan Road, CBD, Zhengzhou, China

No.14 Waihuan Road, CBD, Zhengzhou, China

+86-18703635966

+86-18703635966

No.14 Waihuan Road, CBD, Zhengzhou, China

No.14 Waihuan Road, CBD, Zhengzhou, China

+86-18703635966

+86-18703635966

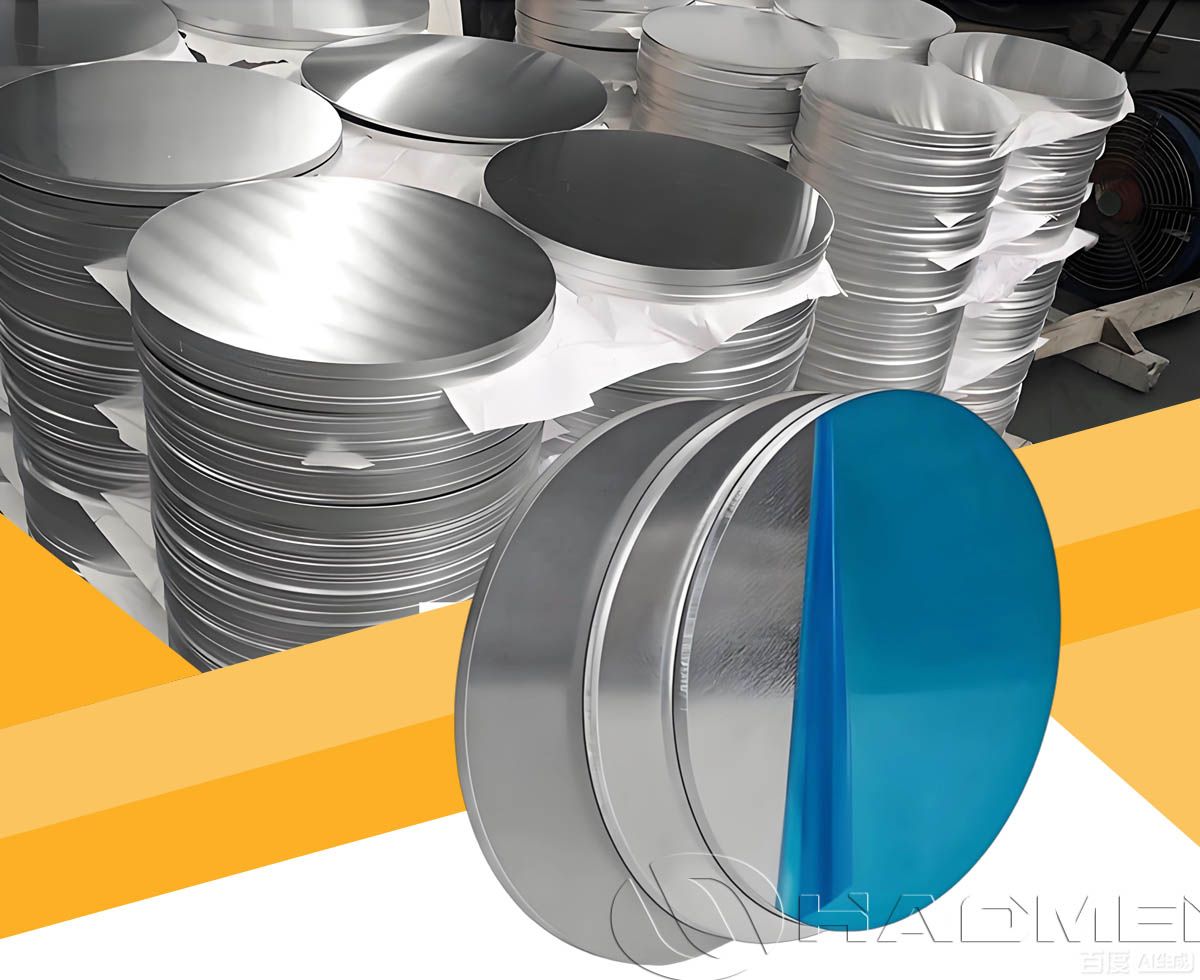

In the cookware manufacturing industry, material quality directly determines product yield and service life. As a professional aluminum material supplier, HAOMEI Aluminum provides 1050, 1060, 1070, and 1100 aluminum discs produced by hot rolling (DC process). Thanks to their excellent ductility and outstanding thermal conductivity, these high-purity aluminum circles have become the preferred choice for manufacturers of non-stick cookware, pressure cookers, and high-end kitchenware.

1050, 1060, 1070, and 1100 hot rolled aluminum circles are round semi-finished aluminum products made from high-purity hot rolled aluminum sheets through precision punching. They are specifically designed for cookware and kitchenware manufacturing.

These aluminum circles feature high purity, uniform grain structure, excellent thermal conductivity, and superior formability, making them ideal materials for producing aluminum woks, non-stick pans, pressure cookers, frying pans, and rice cooker inner pots.

1050 Aluminum (A1050): Aluminum content ≥ 99.5%. A typical industrial pure aluminum with extremely high thermal conductivity, excellent corrosion resistance, and superior ductility. It is easy to deep draw and spin, resulting in lightweight cookware with uniform heat distribution.

1060 Aluminum (A1060): Aluminum content ≥ 99.6%, slightly higher purity than 1050. It offers better electrical and thermal conductivity and stronger corrosion resistance, with stable chemical properties and excellent processing performance.

1070 Aluminum: Aluminum content ≥ 99.7%. With outstanding plasticity, it is especially suitable for complex cold forming processes and is an ideal choice for cookware with complex shapes.

1100 Aluminum: Aluminum content ≥ 99.0%, containing a small amount of copper (about 0.12%). While maintaining good thermal conductivity and corrosion resistance, it offers slightly higher strength and better rigidity after forming.

According to the rolling process, aluminum circles are classified into cold rolled (CC) and hot rolled (DC). For cookware manufacturing-especially processes requiring deep drawing or spinning-hot rolled aluminum circles have a finer and more uniform grain structure and a lower earing rate. Compared with cold rolled aluminum circles, DC aluminum circles are less prone to cracking or "orange peel" defects during deep drawing, making them particularly suitable for high-end cookware with strict forming quality requirements.

Lightweight and Cost-Effective: Aluminum has a low density (about 2.7 g/cm³), resulting in lightweight cookware that is easy to handle. At the same time, material costs and processing energy consumption are relatively low.

Excellent Deep Drawing and Spinning Performance: Hot rolled aluminum circles have high elongation and can withstand large deformation without cracking, making them ideal for deep pots and pressure cookers.

Superior Surface Quality: Smooth and flat surface, free from oil stains, scratches, and oxidation spots. This provides an excellent base for non-stick coatings (such as PTFE) or anodizing.

Outstanding Thermal Conductivity: The excellent heat transfer performance of 1xxx series pure aluminum ensures even heating during cooking and effectively prevents localized overheating.

Controlled Grain Size: Precise annealing processes (O temper, H12, H14, etc.) ensure uniform grain size and prevent surface roughness after forming.

Safe and Hygienic: Compliant with food-contact material requirements, non-toxic, odorless, and safe for cookware applications.

| Product Name | Hot Rolled Aluminum Circle |

| Alloy Grade | 1050 / 1060 / 1070 / 1100 |

| Temper | O |

| Thickness | 0.5 - 6.0 mm |

| Diameter | 100 - 1200 mm (customized available) |

| Rolling Process | DC hot rolling |

| Surface Treatment | Anodizing, coating, polishing, etc. |

| Thermal Conductivity | Excellent |

| Deep Drawing Performance | Suitable for multiple drawing operations |

| Application | Cookware and kitchenware |

| MOQ | 3 tons |

Woks and Frying Pans: Require good heat retention and uniform heat distribution. Commonly use 1060 or 1100 aluminum circles with a thickness of 2.5-3.5 mm to ensure stable temperature during high-heat cooking.

Soup Pots and Milk Pots: Require good deep drawing performance. 1050 or 1070 aluminum circles with a thickness of 1.5-2.5 mm are commonly used for one-time forming.

Pressure Cooker Inner Pots: Require excellent ductility and safety. High-purity 1060 or 1070 aluminum circles are preferred.

Specialty Cookware (e.g., Takoyaki pans, egg pans): Complex shapes require extremely high elongation; 1070 aluminum circles are the optimal choice.

Standard Packaging: Export-grade wooden pallets with inner waterproof film and desiccant, outer cardboard protection, and steel strip strapping.

Customized Logistics: For bulk orders, full container load (FCL) or less-than-container load (LCL) sea freight services are available to ensure safe and intact delivery to your factory.

Copyright © 2026 By HAOMEI Aluminum CO., LTD. All Rights Reserved. Sitemap