No.14 Waihuan Road, CBD, Zhengzhou, China

No.14 Waihuan Road, CBD, Zhengzhou, China

+86-18703635966

+86-18703635966

No.14 Waihuan Road, CBD, Zhengzhou, China

No.14 Waihuan Road, CBD, Zhengzhou, China

+86-18703635966

+86-18703635966

International buyers of aluminum circles often encounter the same problems: inconsistent flatness that complicates stamping, edge burrs that cause tool wear, unstable mechanical properties across batches, and surface defects that show up after anodizing or coating. In many cases, the root issue is not the end-use design but the alloy and temper selection, combined with how the circles are slit, punched, and annealed during production.

A dedicated 1050 1060 1100 H14 aluminum circle factory focuses on controlling these variables so that downstream processesdeep drawing, spinning, stamping, anodizing, or paintingremain stable. This article explains why 1050/1060/1100 (all in the 1000 series) are widely specified, how common tempers (especially H14) behave, and which applications typically match each alloy/temper combination.

The 1000 series is essentially commercially pure aluminum, valued for excellent corrosion resistance, high electrical/thermal conductivity, and reliable formability. For many buyers, the deciding factor is production stability in forming and finishingparticularly when the circles will be deep drawn into cookware, spun into lamp reflectors, or used as blanks for coated signs.

Within this family, 1050, 1060, and 1100 are frequently chosen because they balance purity-driven performance with wide availability. While exact chemistry ranges are defined by standards, the practical difference for buyers is that higher-purity grades generally provide better conductivity and corrosion performance, while still maintaining strong forming behavior.

When H14 temper is specified, circles are supplied in a strain-hardened condition, offering more rigidity and dent resistance than fully annealed material. This helps in applications where the blank must maintain shape during handling or where moderate strength is needed without moving into high-strength alloy systems.

1050/1060/1100 circles are commonly used in environments where corrosion resistance is criticalkitchens, outdoor signage, humid coastal regions, and lighting components. Surface consistency also matters for:

Anodizing (uniform appearance and color response)

Coating/painting (reduced risk of pinholes and visible defects)

Polishing and brushing (repeatable finish across lots)

For heat transfer or electrical uses, commercially pure aluminum offers a strong baseline. Typical examples include:

Heat-related cookware performance (even heat distribution)

Lighting components that benefit from thermal stability

Electrical-related parts where conductivity is important (subject to the buyers design and compliance requirements)

A major reason overseas buyers choose 1000 series circles is their forming window. In practical production terms, a suitable temper and controlled grain structure help reduce:

Earing during deep drawing

Orange-peel surface after forming

Edge cracking during spinning

For deep drawing-intensive products, many buyers choose softer conditions (O temper) rather than H14. However, H14 remains useful when higher rigidity is needed and the forming depth is moderate.

Although they are all non-heat-treatable 1000 series alloys, each grade is often selected for a slightly different balance of availability, forming preference, and finish requirements:

1050 aluminum circle: widely used for cookware and general forming; valued for stable processing and broad market acceptance. Many buyers specify it for standard pan and pot ranges. In product selection discussions, 1050 Aluminum Circle is often used as the baseline reference for 1000 series blanks.

1060 aluminium circle: commonly selected when buyers prioritize higher conductivity and very good forming behavior, especially for spinning and lamp-related components. It is also used where consistent surface finish is needed across high-volume production. For common specifications, 1060 Aluminium Circle is frequently compared against 1050 during sourcing.

1100 aluminum circle: a classic choice for chemical resistance and forming; widely used in general fabrication and finishing applications. It is often considered when buyers need a widely recognized commercial-purity grade with good workability.

In procurement, the more important decision is often not only the alloy number, but also the temper, the surface/edge requirements, and whether circles are intended for deep drawing versus stamping.

Aluminum circles are typically supplied in annealed or strain-hardened tempers. The temper affects strength, springback, and forming limits.

Best for: deep drawing, severe spinning, and parts requiring maximum ductility.

O temper is used when the part must undergo significant deformation, such as deep cookware bodies, large lamp shades, or components with tight radii. Buyers often choose O temper to minimize cracking risk and reduce forming force.

Best for: light stamping, shallow forming, and improved handling stiffness.

H12 provides more strength than O temper while still offering usable formability. It can be practical where blanks must resist minor dents during transport or feeding.

Best for: moderate stamping, shallow drawing, and applications needing higher rigidity.

H14 is widely specified because it offers a workable balance: stronger and more rigid than H12, but still formable enough for many parts that do not require severe drawing. Typical uses include:

Sign blanks that need stiffness

Shallow cookware components and lids

Some lighting and decorative parts formed by moderate spinning

In production terms, H14 often supports better dimensional stability during handling, stacking, and automated feeding.

Best for: higher stiffness parts with minimal forming.

H16 is less common for parts requiring drawing/spinning, but can be used where the circle is mainly a blank for cutting, punching, or simple forming.

Note: Actual property requirements should be agreed against the applicable standard and buyer specification; temper alone does not define all performance outcomes.

Flatness affects tool alignment, scrap rate, and stamping stability. Residual stress can lead to warping after cutting or during forming. Buyers typically confirm:

Flatness tolerance expectations for their press lines

Whether circles are produced via punching from sheet/coil with controlled leveling

Suitability for spinning (which can amplify stress-related distortion)

Burrs can cause die damage, scratching, and inconsistent forming. For cookware and visible parts, edge condition also affects safety and finishing. A stable factory process aims to keep:

Smooth edges

Minimal burr height

Consistent diameter accuracy for automated feeding

For anodized cookware components, lighting reflectors, or coated signs, surface cleanliness and uniformity are critical. Buyers typically specify:

No oil stains or embedded particles

Controlled surface scratches (depending on finish class)

Packaging that protects surfaces during ocean transport

Many cookware components rely on the forming behavior and thermal conductivity of 1000 series aluminum circles. Typical items include:

Frying pans and non-stick pans (as blanks for formed bodies)

Pressure cooker components

Lids, shallow drawn parts, and bases

The alloy/temper is selected based on draw depth and downstream finishing (non-stick coating, anodizing, polishing). For deep-drawn cookware bodies, O temper is commonly used; for parts requiring more rigidity with limited deformation, H14 can be appropriate.

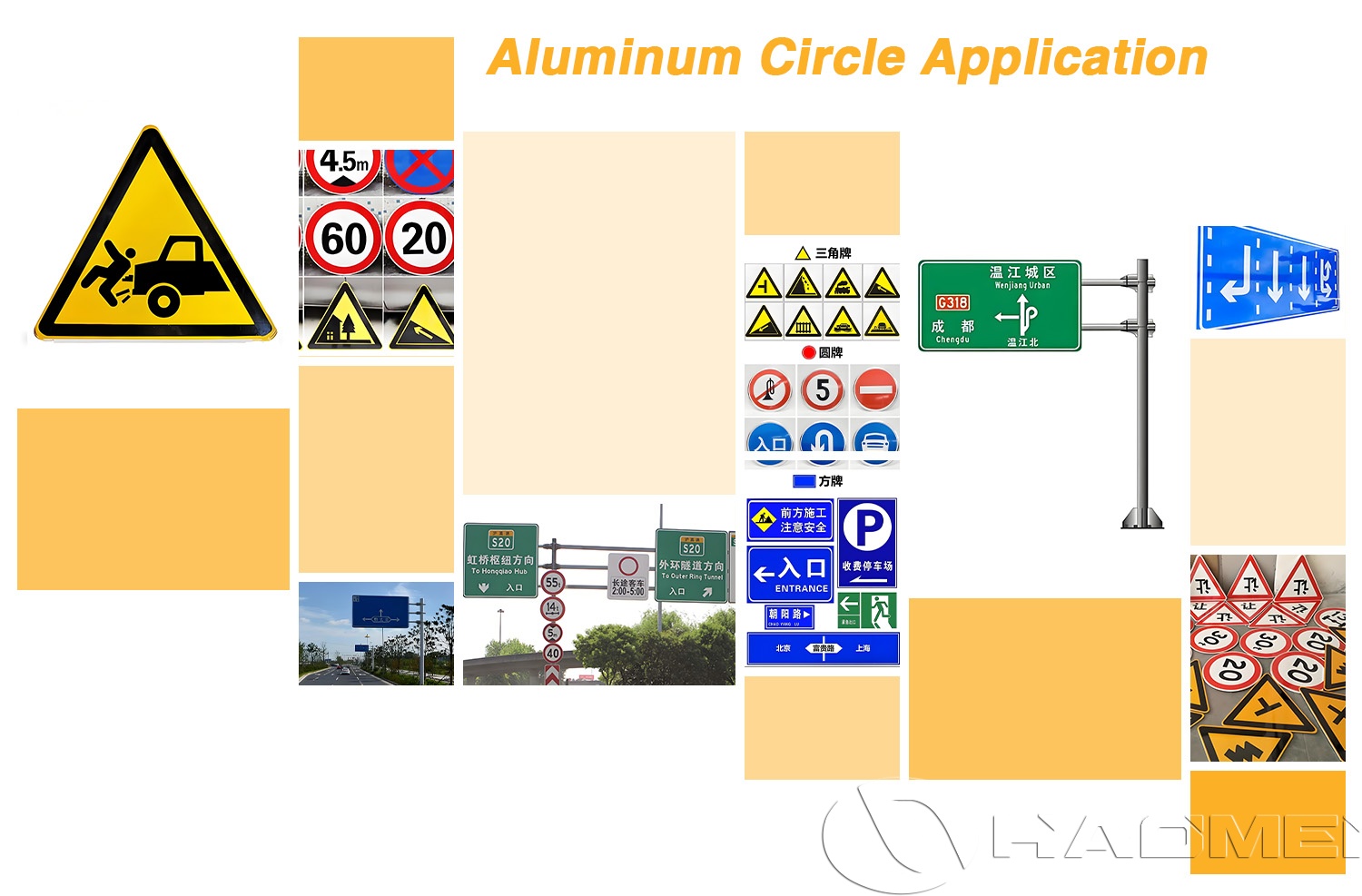

Aluminum circles/discs are used as blanks in sign production due to corrosion resistance and outdoor durability. H14 can be favored where stiffness helps maintain flatness, particularly when the blank will be coated or laminated.

Spun lamp shades and reflectors often use 1050/1060/1100 due to formability and finish. 1060 is frequently selected where consistent spinning and surface appearance are priorities.

Depending on design requirements, commercially pure aluminum circles can be used for enclosures, decorative covers, and parts where corrosion resistance and finishing are more critical than high strength.

The table below lists widely used industry references and parameter categories. Exact values (chemical limits, mechanical properties, tolerances) depend on the specific standard edition and the agreed purchase specification.

| Item | What it Covers | Common References (Examples) | Notes for Buyers |

|---|---|---|---|

| Alloy designation | Alloy numbering and chemical composition limits | EN AW (EN 573 series), AA/ASTM alloy designations | 1050/1060/1100 are 1000 series commercially pure aluminum alloys under different designation systems. |

| Temper designation | Temper definitions for wrought aluminum | EN 515, ANSI H35.1 | Defines O, H12, H14, etc.; does not alone guarantee performance without thickness and processing context. |

| Mechanical properties | Strength/elongation requirements by alloy/temper/thickness | EN 485 series, ASTM B209 | Values vary by thickness and standard; confirm by mill test documentation where applicable. |

| Dimensional tolerances | Thickness, width/diameter, flatness tolerances | EN 485 series, ASTM B209 (for sheet/plate); circle tolerances often agreed by contract | Circle/disc tolerances may be buyer-specified; confirm diameter tolerance and burr allowance. |

| Quality documentation | Inspection and test documents | EN 10204 | Common documents include 2.2 or 3.1 depending on agreement. |

Selecting 1050, 1060, or 1100 aluminum circles is often less about marginal chemistry differences and more about achieving predictable forming, stable finishing results, and consistent batch-to-batch behavior. For deep drawing and severe spinning, O temper is typically the safest choice. For applications needing improved stiffness and handling stability with moderate forming, H14 is commonly used.

Copyright © 2026 By HAOMEI Aluminum CO., LTD. All Rights Reserved. Sitemap