-

-

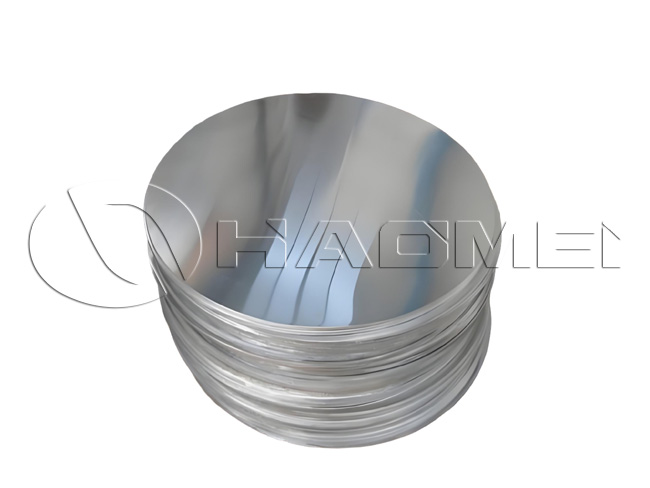

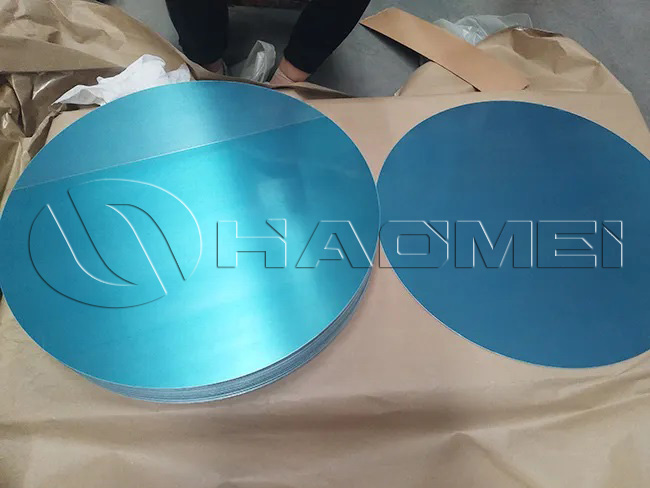

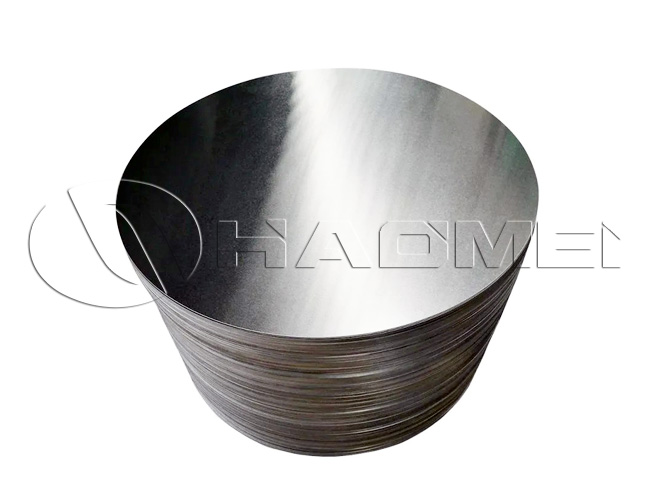

Color Coated Aluminum Circle

- Alloy 1050/1060/1070/1100/1200/3003/3004/3005/3105/5005/5052/6061/etc

- Temper O, H12, H14, H16, H18, H19, H22, H24, H26, etc.

- Thickness 0.50 mm – 6 mm

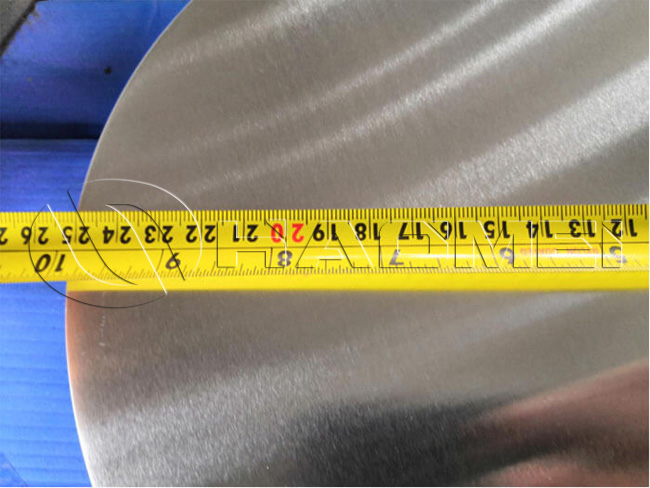

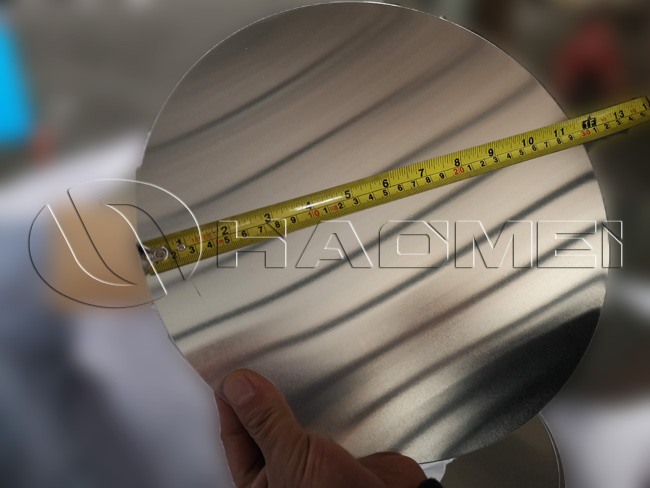

- Diameter 100 mm – 1520 mm

- Colors White, black, gold, etc., customizable upon request

- Surface Finish Anodized, polished, non-stick coated, etc.

HAOMEI Aluminum – Color Coated Circle Supplier

HAOMEI Aluminum specializes in the production, export, and supply of coated aluminum circles. We can provide paints in the colors you require, based on RAL or Pantone standards. Our color-coated aluminum circles feature vivid colors and patterns, and are widely used in kitchen cookware, lighting, signage, and more.

What is a Color Coated Aluminum Circle Disc?

A color-coated aluminum circle refers to an aluminum alloy circle substrate (such as series 1xxx, 3xxx, 5xxx, etc.) that is cleaned, pretreated (such as chromating or passivation), coated by spraying, and cured by baking. One or both sides can be covered with one or multiple layers of organic coatings (such as PE polyester, PVDF fluorocarbon, etc.), resulting in a functional and decorative product. These are widely used in transportation, cookware, decoration, electronics, and other industries.

Why Apply Coatings?

Decorative Appeal: The most obvious purpose. Any RAL or Pantone color can be achieved, along with special effects such as wood grain, stone grain, or brushed metallic finishes, greatly enhancing product aesthetics.

Weather Resistance & Anti-Aging: High-quality coatings resist UV rays, rain, acid rain, and salt spray, protecting the aluminum substrate from corrosion while maintaining color and gloss for long service life.

Chemical Resistance: Coatings withstand daily cleaning agents, oils, and chemicals, ensuring durability and easy maintenance.

Physical Protection: Coatings add resistance to wear and scratches, protecting the aluminum surface.

Special Functions: Specific coatings can provide antibacterial, self-cleaning, or anti-fingerprint properties.

Product Information - Color Coated Aluminum Circles

| Alloy | 1050/1060/1070/1100/1200/3003/3004/3005/3105/5005/5052/6061 |

| Temper | O, H12, H14, H16, H18, H19, H22, H24, H26, etc. |

| Thickness | 0.50 mm - 6 mm |

| Diameter | 100 mm - 1520 mm |

| Colors | White, black, gold, etc., customizable upon request |

| Surface Finish | Anodized, polished, non-stick coated, etc. |

| Hardness | 26-29 |

| Elongation | 36%-45% |

| Surface Options | Coated or non-coated |

| Shape | Discs, circular shapes |

| Applications | Kitchen cookware, lighting, signage, etc. |

Common coating types for aluminum wafers

PE (Polyester):

Cost-effective, rich in color options, good flexibility and adhesion, moderate weather resistance. Widely used in household appliances, indoor products, lighting, and general outdoor applications.

HDPE (High-Durability Polyester):

Better weather resistance than standard PE, with stronger UV resistance. Suitable for outdoor applications requiring higher durability.

PVDF (Polyvinylidene Fluoride):

Outstanding weather resistance and UV protection, excellent color retention, and resistance to chalking. More expensive, ideal for exterior walls, outdoor signage, and harsh industrial environments requiring long service life.

EP (Epoxy):

Excellent adhesion, chemical resistance, and hardness, but poor weather resistance (chalks under sunlight). Typically used as primer or for indoor/underground functional components.

Key Features of Color Coated Aluminum Circles

Aesthetic Variety: Wide range of colors, including solid shades, metallic finishes, wood grain, and stone effects, meeting diverse design requirements.

Excellent Weather Resistance: Coatings effectively resist UV rays, acid rain, and pollutants, preventing oxidation and fading, and extending service life.

Superior Corrosion Resistance: Coating forms a protective barrier, isolating the aluminum substrate from corrosive environments, especially in humid or salt-spray conditions.

Good Workability: Maintains ductility and deep-drawing performance after coating, enabling stamping, stretching, and other secondary processes without cracking or peeling.

Lightweight & Eco-Friendly: Retains aluminum’s lightweight properties for easy handling and installation. Coatings are compliant with environmental standards, non-toxic and safe.

Application Fields of Color Coated Aluminum Circles

Home Appliances: Air conditioner panels, washing machine panels, microwave oven fronts, water heater shells, etc. (one of the largest application fields).

Lighting: Indoor and outdoor lamp reflectors, lampshades, and decorative rings, offering both beauty and reflectivity.

Architectural Decoration: Exterior wall panels, ceiling panels, signage, and indoor decoration.

Furniture & Homeware: Cabinet panels, furniture handles, photo frames, gift boxes, etc.

Cookware: Used for pot lids or outer decorative parts, providing both aesthetics and surface protection.

Electronics: Audio system panels, router housings, etc.

Traffic Signs: In specific cases, color-coated aluminum circles are used for traffic signs requiring designated colors.

How to Select the Right Color Coated Aluminum Circle?

Coating Adhesion: Perform a cross-cut test (scratch with a blade in a grid pattern, apply tape, and check for peeling). Poor adhesion leads to easy paint loss.

Weather Resistance: Choose coating type based on usage (PVDF/SMP for outdoor, PE/Epoxy for indoor), and request salt spray resistance test reports.

Color Consistency: Require color card samples from the supplier to ensure batch uniformity without visible color differences.

No.14 Waihuan Road, CBD, Zhengzhou, China

No.14 Waihuan Road, CBD, Zhengzhou, China +86-18703635966

+86-18703635966

+86-18703635966

+86-18703635966

sales@alummc.com

sales@alummc.com

8618703635966

8618703635966