No.14 Waihuan Road, CBD, Zhengzhou, China

No.14 Waihuan Road, CBD, Zhengzhou, China

+86-18703635966

+86-18703635966

No.14 Waihuan Road, CBD, Zhengzhou, China

No.14 Waihuan Road, CBD, Zhengzhou, China

+86-18703635966

+86-18703635966

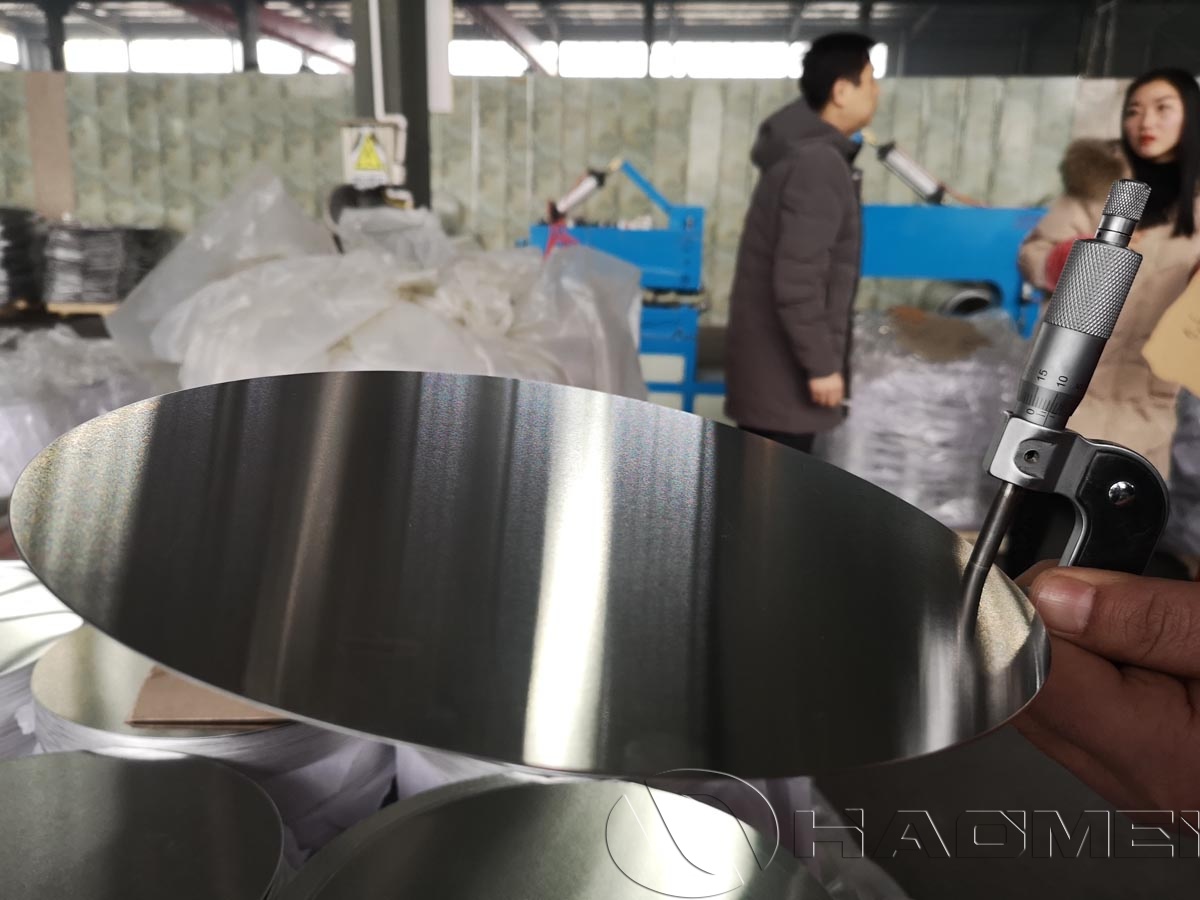

Mirror finish 3003 aluminum discs are widely specified when end products require both high formability and a premium reflective appearance. As a manufacturer of aluminum circles and discs, we produce 3003 alloy discs with controlled chemistry, consistent grain structure, and surface preparation suitable for mirror polishing, spinning, and deep drawing. Typical downstream products include cookware bottoms, lighting reflectors, decorative covers, and components that will be anodized or further polished.

The term "mirror finish" in disc production is not only a visual requirement. It implies disciplined control of coil surface quality, rolling marks, lubrication residues, and micro-defects that can become visible after polishing, anodizing, or forming. For 3003 aluminum (Al-Mn), the alloy offers a strong balance of drawability, corrosion resistance, and stable mechanical behavior, making it a practical choice for high-volume parts where consistent forming yield matters.

3003 aluminum is a non-heat-treatable 3xxx series alloy strengthened primarily by manganese. Compared with commercially pure aluminum grades, 3003 provides improved strength while maintaining excellent formability. This is important for mirror-finish applications because deep drawing and spinning can amplify surface imperfections. A stable alloy and predictable elongation help reduce orange peel, tearing, and uneven reflection after forming.

From a manufacturing perspective, mirror-grade discs require:

Clean base metal and controlled inclusion levels to minimize pinholes and polishing defects.

Fine and uniform grain structure to reduce surface waviness after drawing.

Stable mechanical properties across the coil width and along the length to keep forming behavior consistent lot to lot.

For buyers sourcing a dedicated product, our 3003 Aluminum Circle program is designed for repeated forming and finishing operations, including mirror polishing and bright anodizing process compatibility.

We supply mirror aluminum discs as either:

Bright rolled base with controlled surface intended for customer-side polishing.

Pre-finished polished surface where specifications require a defined reflective appearance and strict defect limits.

Key surface controls include:

Tight limits for rolling lines, chatter, dents, scratches, and edge nicks.

Degreasing and cleanliness control to reduce polishing haze.

Consistent reflectivity response across batches when processed under the same polishing parameters.

3003 alloy is routinely used for:

Deep drawing with controlled earing behavior.

Spinning and flow forming where uniform ductility is required.

Secondary finishing such as anodizing, brushing, and polishing.

Disc flatness, grain uniformity, and edge condition directly influence forming yield. We control blanking parameters and apply edge deburring where needed to reduce crack initiation during spinning.

3003 provides solid corrosion resistance in typical indoor and mild outdoor environments. For cookware and lighting components, it offers practical durability. Where aggressive environments are expected, we support alloy selection guidance or post-treatment recommendations.

The following table summarizes common manufacturing ranges. Final supply is confirmed by purchase specification and application requirements.

| Item | Typical Range / Option | Notes |

|---|---|---|

| Alloy | 3003 | Al-Mn alloy, non-heat-treatable |

| Temper | O, H12, H14, H16, H18 | O for deep drawing and spinning; H tempers for stiffness |

| Disc diameter | 80 mm to 1200 mm | Larger diameters available subject to tooling |

| Thickness | 0.5 mm to 6.0 mm | Customized thickness ranges available |

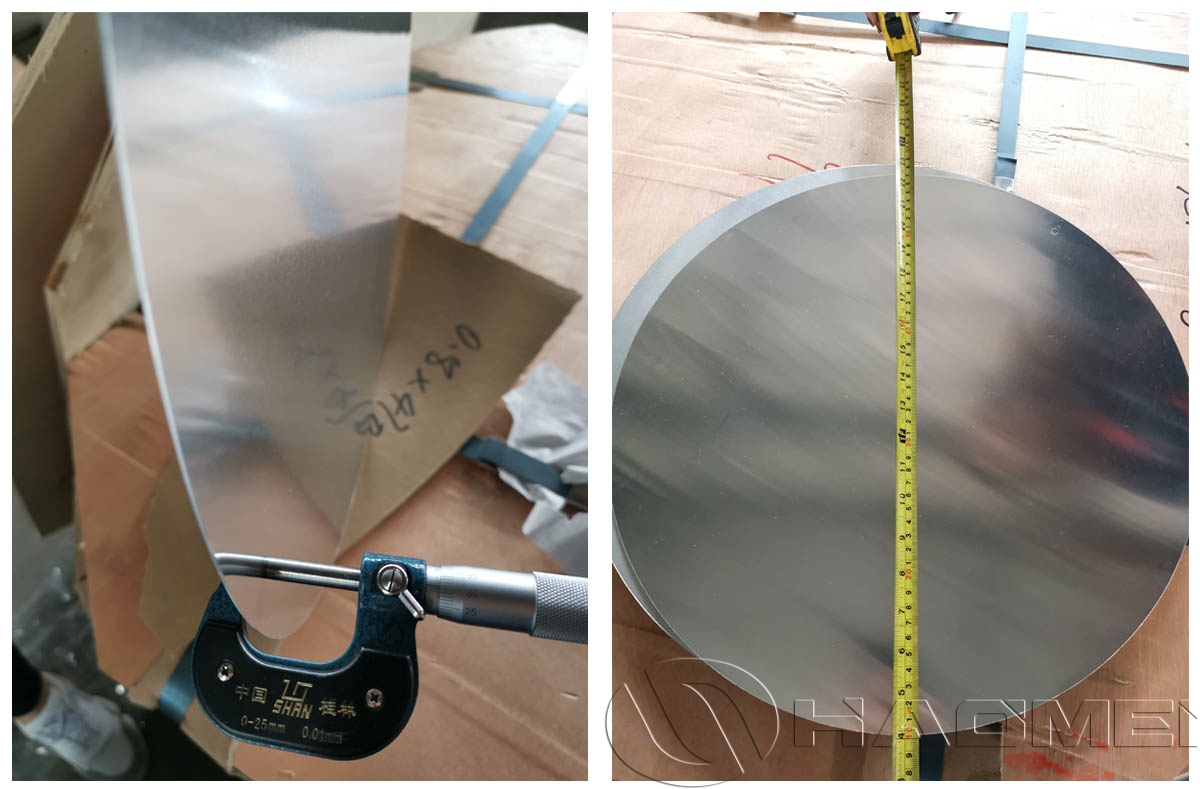

| Thickness tolerance | As agreed (tight control available) | Depends on thickness and diameter |

| Diameter tolerance | As agreed (tight control available) | Based on blanking method and size |

| Flatness | Controlled per application | Critical for reflector and decorative parts |

| Surface finish | Bright base, polished, mirror finish | Defined by Ra/visual criteria and inspection method |

| Edge | Mill edge trimmed, deburred optional | Burr control supports forming yield |

| Protective film | Optional | Helps prevent handling scratches |

| Packaging | Export seaworthy, palletized | Moisture protection and interleaving available |

Mirror-finish discs depend on the starting coil. We select coils based on surface class, mechanical property targets, and traceable heat/lot management. Process control focuses on:

Rolling and tension control to limit surface chatter and waviness.

Lubricant management and cleaning to reduce embedded residues.

Heat treatment/annealing control for temper consistency and drawability.

Disc manufacturing includes blanking and punching operations designed to maintain dimensional consistency and minimize edge defects. Burr height and edge microcracks can create failures during spinning. For demanding applications, we supply discs with controlled burr direction and optional edge finishing.

Depending on the customer specification, we support two routes:

Mirror-ready surface: controlled bright rolled surface suitable for customer polishing lines.

Factory mirror finish: polishing with defined inspection criteria (visual and/or instrument-based).

Because mirror appearance is sensitive to handling, packaging can include interleaving paper, PE film, and edge protection.

As a factory supplier, we run in-process and final inspections for dimensions, surface, and mechanical properties. Typical controls include:

Incoming coil inspection for surface and thickness profile.

In-process monitoring of blanking parameters and tool condition.

Final inspection for diameter, thickness, flatness, and appearance.

Traceability by heat number and production lot to support process consistency and corrective actions.

Our inspection method and acceptance criteria are aligned with the agreed standard and the customer drawing. We can support common international requirements for aluminum sheet/disc supply, and we regularly provide certificates including chemical composition and mechanical property results per lot.

Mirror finish 3003 aluminum discs are often engineered for the downstream forming and finishing process. We offer customization in:

Diameter, thickness, and tolerance class.

Temper selection based on drawing ratio and forming method.

Surface class and defect limit agreement (visual standard samples can be approved).

Protective film type and interleaving method.

Packaging configuration for automated feeding lines.

For buyers who source multiple 3xxx alloys for different product lines, we can also supply 3000 Series Aluminum circle grades under one quality system and consistent packaging requirements.

Mirror polished aluminum circles and mirror finish 3003 aluminum discs are used when both forming and surface aesthetics matter. Common applications include:

Cookware and kitchenware: pot bases, lids, pressure cooker components, and spun parts.

Lighting and reflectors: lamp reflectors, decorative light covers, and reflective housings.

Decorative and architectural components: covers, trim rings, and cosmetic panels formed from discs.

Anodizing and surface finishing: parts requiring bright anodized appearance, brushed plus polished effects, or multi-step finishing.

Industrial components: spun shells, small housings, and deep drawn parts where cosmetic quality is still required.

When customers share forming details such as draw depth, punch radius, lubrication type, and annealing steps, we can recommend the appropriate temper and surface preparation to reduce rejection rates.

When selecting disc material for a mirror-finish part, buyers often compare across different alloy families or surface routes. In practical production, mirror finish 3003 aluminum discs provide several measurable advantages:

Better strength-formability balance than very soft, high-purity grades in many deep drawing and spinning operations.

Stable forming behavior with predictable response lot to lot when temper and grain structure are controlled.

Good corrosion resistance for general-purpose cookware and lighting use.

Surface controllability: 3003 coils can be processed to a consistent bright base suitable for polishing, helping reduce polishing time and rework.

Cost-effective processing route for high-volume discs where both cosmetic and mechanical consistency are required.

The final selection should consider the downstream process window. For example, extremely high reflectivity requirements may drive additional polishing steps and stricter base-metal surface limits, while maximum draw depth may favor fully annealed temper and controlled earing.

As a manufacturer of mirror finish 3003 aluminum discs, we focus on repeatable quality rather than one-time batches. Our production management emphasizes coil traceability, disciplined surface control, and dimensional consistency, because mirror applications expose defects that standard industrial parts may tolerate.

We support customers with:

Stable supply planning for recurring disc sizes.

Technical alignment on temper, surface class, and defect limits based on forming and finishing steps.

Lot documentation and quality records to maintain consistent downstream performance.

For long-term programs, we can jointly establish reference samples, inspection checkpoints, and packaging standards to protect mirror surfaces through shipping and handling, ensuring your forming and finishing lines run with predictable yield.

Copyright © 2026 By HAOMEI Aluminum CO., LTD. All Rights Reserved. Sitemap