No.14 Waihuan Road, CBD, Zhengzhou, China

No.14 Waihuan Road, CBD, Zhengzhou, China

+86-18703635966

+86-18703635966

No.14 Waihuan Road, CBD, Zhengzhou, China

No.14 Waihuan Road, CBD, Zhengzhou, China

+86-18703635966

+86-18703635966

Mirror finish 3003 aluminum circles are widely specified when a component must be formed from a round blank and also present a highly reflective appearance after finishing. In practical engineering terms, the product combines two requirements that often conflict: stable deep-drawing behavior and a surface suitable for mirror polishing, bright anodizing, or decorative coating.

As a manufacturer producing aluminum circles from coil and plate, we are frequently asked about mirror finish 3003 aluminum circle price. Price is not only linked to alloy and thickness. It is strongly influenced by surface targets, allowable defects, flatness, protective packaging, and the process route used to achieve mirror-level reflectivity.

This article explains the technical drivers behind mirror finish 3003 aluminum disc performance and pricing, based on our factory production and inspection experience.

3003 is an Al-Mn alloy known for reliable forming, consistent mechanical properties, and good corrosion resistance in everyday environments. For mirror-finish circles, 3003 is selected when customers require:

Stable deep drawing and spinning performance.

Good surface response for mechanical polishing and bright finishing.

Predictable behavior under anodizing and organic coatings.

Cost-effective alloying compared with higher-strength options.

For buyers comparing multiple product options, our production scope includes 3000 Series Aluminum circle grades, with 3003 being the most common choice for mirror appearance plus forming.

Mirror finish is typically achieved through one of the following approaches, depending on customer specifications:

High-quality base stock plus controlled polishing to reach the required reflectivity.

Bright surface routes suitable for subsequent bright anodizing.

Controlled surface quality (low inclusion, low streak risk) to ensure cosmetic consistency after customer-side polishing or anodizing.

From a factory perspective, the key is not only initial gloss, but also surface consistency across the whole lot so that downstream finishing yields a uniform appearance.

Below are typical parameters we manufacture for mirror finish 3003 aluminum circles. Final values can be tailored to the forming method and finishing plan.

| Parameter | Typical Range / Option | Notes |

|---|---|---|

| Alloy | 3003 (Al-Mn) | Chemical composition per relevant aluminum standards and agreed mill tolerance |

| Temper | O, H12, H14, H16, H18 (on request) | O for deep drawing, H tempers for stiffness and handling |

| Thickness | 0.30 mm to 6.00 mm | Common cookware and lighting: 0.6 mm to 3.0 mm |

| Diameter | 80 mm to 1200 mm | Larger diameters subject to thickness and flatness constraints |

| Thickness tolerance | As agreed (typical tight control available) | Impacts spinning stability and weight control |

| Diameter tolerance | As agreed | Depends on blanking method and end use |

| Surface finish | Mirror-ready, polished, or bright base | Defined by reflectivity target and defect criteria |

| Flatness | Controlled per application | Especially important for reflector and cover applications |

| Edge quality | Deburred, smooth edge | Critical for safe handling and forming |

| Protective film | PE film optional | Recommended for cosmetic parts |

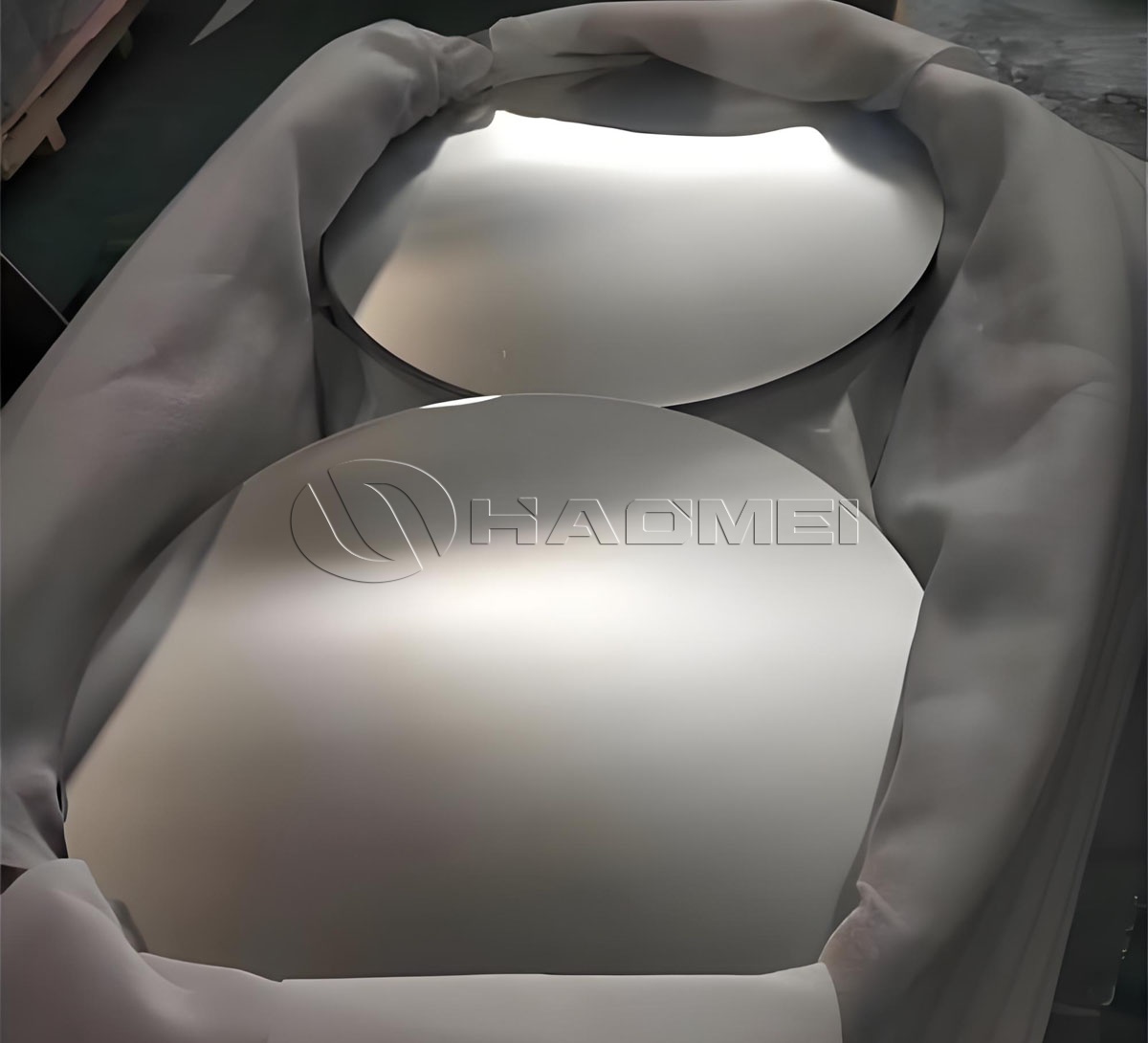

| Packing | Export wooden pallet or case | Moisture barrier and interleaving optional |

Our mirror finish 3003 aluminum circles are produced through a controlled route designed to protect surface quality:

Raw material selection and incoming inspection (chemistry, surface, mechanical baseline).

Slitting and leveling to reduce residual stresses.

Blanking by precision punching or cutting methods suited to diameter and thickness.

Deburring and edge conditioning to minimize cracking risk during drawing.

Surface preparation steps based on the defined mirror requirement.

Final inspection and protected packing for export.

The main variable affecting both performance and mirror finish 3003 aluminum circle price is the degree of surface control and the number of surface-related operations required.

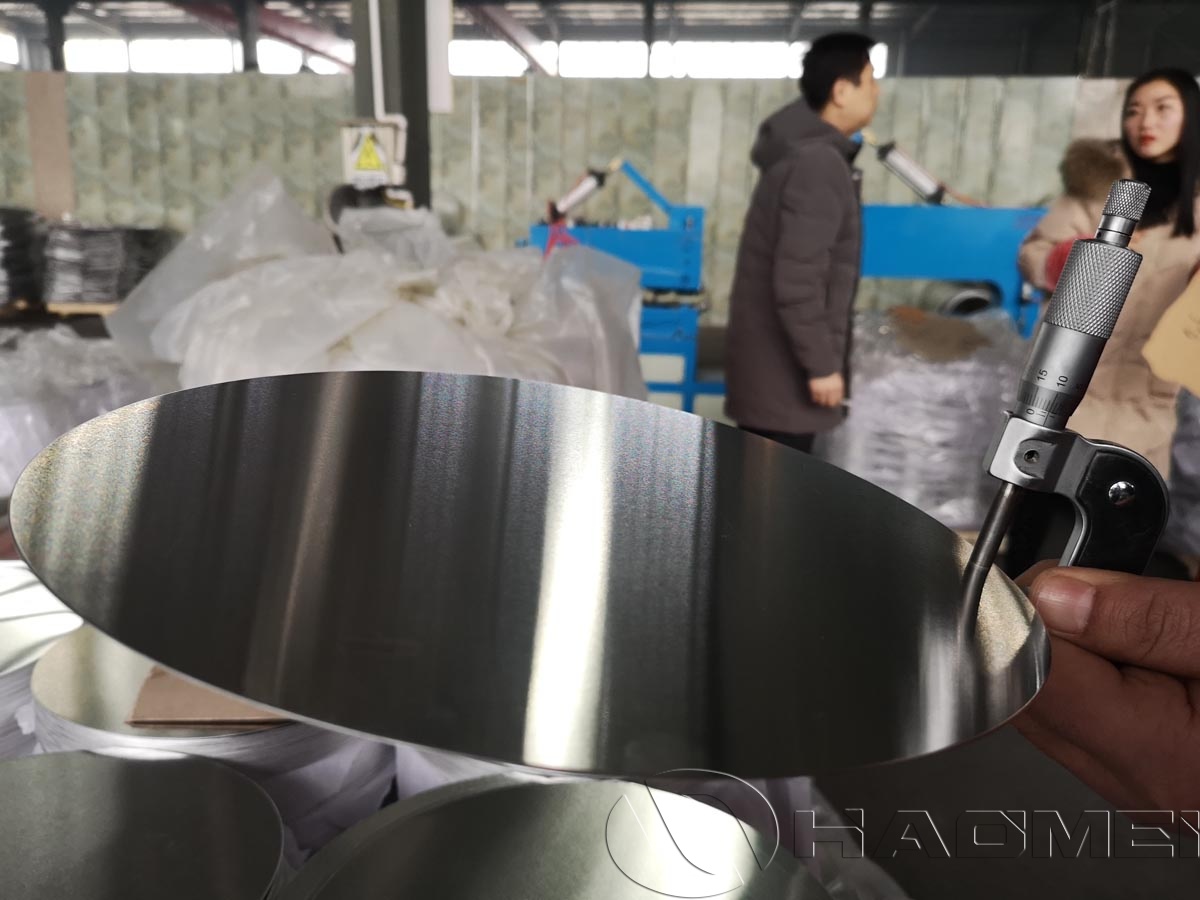

We apply routine and application-focused inspections, including but not limited to:

Thickness measurement across the circle to verify uniformity.

Visual inspection under defined lighting for scratches, streaks, and dents.

Flatness monitoring for reflector and cover applications.

Edge inspection to confirm burr limits and smoothness.

Lot traceability for stable repeat supply.

We can provide documentation aligned with common international requirements, such as material test certificates (MTC) with chemical composition and mechanical properties, and production traceability records. Where customers require specific acceptance criteria for cosmetic surfaces (for example, critical scratch length limits), we define them in advance and inspect accordingly.

Because mirror-finish circles are often used in visible parts, customization is typically required. We support:

Alloy and temper selection (commonly 3003-O for deep drawing).

Tight thickness and diameter tolerances for automated forming lines.

Mirror-ready surface targets based on your polishing or anodizing plan.

PE film protection (single or double side) to reduce handling marks.

Special packing to prevent rub marks, moisture staining, and transit deformation.

If your project requires a defined base for subsequent anodizing, we can align the surface condition and inspection method with your anodizing line capability. Our 3003 Aluminum Circle production is commonly specified for cookware blanks, lighting reflectors, signage, and decorative panels.

Mirror finish 3003 aluminum circles are typically selected for parts that combine forming with appearance:

Pots, pans, pressure cooker components, and lids.

Spinning and deep drawing blanks where surface consistency reduces polishing workload.

Applications requiring uniform wall thickness and low earing tendencies.

Reflector bases and decorative trim rings.

Parts requiring stable flatness and a clean surface to achieve high reflectance.

Bright anodized covers, nameplates, cosmetic housings, and architectural accessories.

Components where a controlled base material reduces anodizing streaks and patchiness.

Round covers, end caps, and protective discs.

Components where corrosion resistance and appearance both matter.

As a factory, we quote based on measurable cost drivers and acceptance criteria. The following factors typically have the largest influence:

Alloy and temper: O temper for deep drawing may require stricter control of surface and grain structure depending on forming severity.

Thickness and diameter: Larger diameter and tighter tolerances increase process control demands and yield loss.

Surface quality level: Mirror-ready standards with strict limits on scratches, pits, roll marks, and inclusions increase inspection time and rejection risk.

Flatness and residual stress control: Required for reflectors and cosmetic covers, often adding leveling and tighter process windows.

Protective film and packing: Film type, application quality, interleaving, and export-grade moisture protection impact total cost.

Order quantity and mix: Stable batch size improves coil utilization and reduces changeover.

Testing and documentation: Additional mechanical testing, special sampling plans, or customer-specific inspection records.

For accurate pricing, we recommend sharing your target diameter, thickness, temper, surface requirement (mirror-ready vs polished), and intended finishing method (polishing, anodizing, coating). This lets us match the process route and provide a quote aligned with your acceptance criteria rather than a generic grade-only price.

Mirror finish 3003 aluminum circles are not a commodity item when cosmetic acceptance criteria are strict. Stable supply depends on disciplined process control, consistent raw material selection, and repeatable inspection methods.

As a manufacturing source, we support customers with:

Repeatable production routes for long-term programs.

Clear, written surface acceptance criteria and sampling plans.

Engineering communication for forming issues such as earing, orange peel, or surface print-through.

Export packing designed to protect mirror-sensitive surfaces during transit.

If you are evaluating mirror finish 3003 aluminum circle price for cookware, lighting, or anodized components, we can review your drawings, finishing steps, and quality targets to propose the most suitable temper, surface route, and packaging configuration for stable production over time.

Copyright © 2026 By HAOMEI Aluminum CO., LTD. All Rights Reserved. Sitemap