No.14 Waihuan Road, CBD, Zhengzhou, China

No.14 Waihuan Road, CBD, Zhengzhou, China

+86-18703635966

+86-18703635966

No.14 Waihuan Road, CBD, Zhengzhou, China

No.14 Waihuan Road, CBD, Zhengzhou, China

+86-18703635966

+86-18703635966

In modern industry, material performance directly determines product quality and durability. As one of the most popular members of the aluminum alloy family, 6061 aluminum discs are widely regarded as a preferred material across automotive, aerospace, marine, construction, and sporting goods industries. Their popularity stems from an excellent balance of mechanical strength, corrosion resistance, and machinability.

6061 aluminum alloy belongs to the Al-Mg-Si (aluminum-magnesium-silicon) series and is a heat-treatable, precipitation-hardened alloy. Compared with commonly used 1060 or 3003 aluminum discs, 6061 contains magnesium and silicon that form the strengthening phase Mg₂Si, significantly improving mechanical strength.

High Strength

Tensile strength up to 310 MPa and yield strength up to 276 MPa, suitable for most structural applications.

Excellent Machinability

Outstanding cutting performance and cold workability, ideal for turning, milling, drilling, stamping, and other precision machining processes.

Good Corrosion Resistance

Particularly after anodizing, a hard and corrosion-resistant oxide layer forms on the surface, offering both protection and an attractive appearance.

Moderate Density with Good Conductivity

Lightweight yet with favorable electrical and thermal conductivity, supporting efficient heat dissipation and structural optimization.

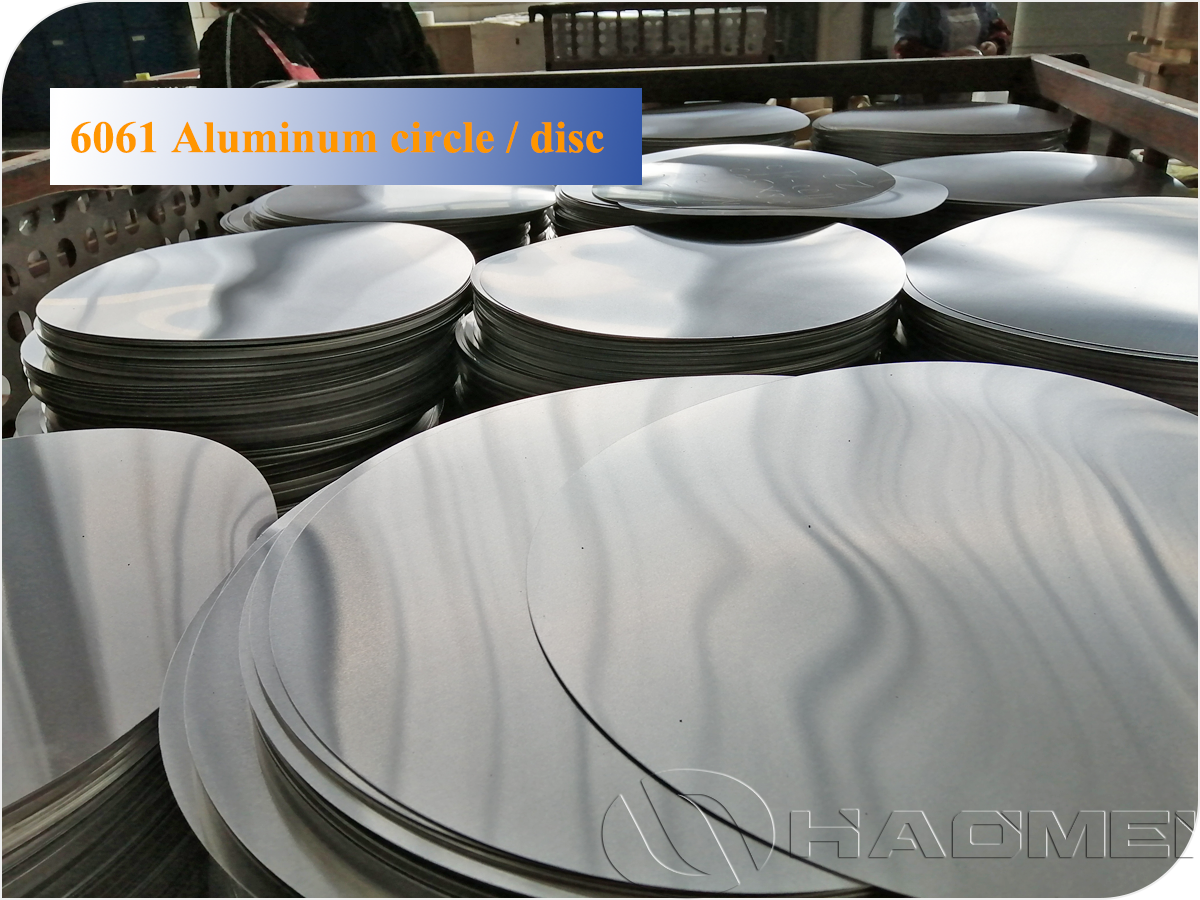

A 6061 aluminum circle is a circular blank manufactured from 6061 aluminum plate or coil through precision stamping, CNC turning, or laser cutting. Its core value lies in providing a standardized, pre-processed base material for downstream manufacturing.

HAOMEI Aluminum supplies aluminum discs with thicknesses from 0.5-6.0 mm and diameters from 10-2000 mm, and offers multiple surface finishes such as mirror polish, brushed finish, anodizing (natural, black, etc.), and coating to fully meet customized requirements.

| Alloy | 6061 |

| Series | Al-Mg-Si |

| Temper | O / T4 / T6 / T651 |

| Diameter Range | 50-1,200 mm |

| Thickness Range | 0.5-6.0mm |

| Surface Finish | Mill finish / Brushed / Anodized / Coated / Customized |

| Applications | Cookware, automotive, marine, flanges, precision components |

| Packaging | Standard export wooden pallet or wooden case |

| MOQ | 1-3 tons |

| Tensile Strength | 276 MPa |

| Yield Strength | 248 MPa |

| Elongation | ≥ 8% |

| Thermal Conductivity | 167 W/(m·K) |

| Density | 2.7 g/cm³ |

Cookware and cookware bases

Lighting fixtures and accessories

Mechanical equipment components

Aluminum flanges and end caps

Pressure vessel parts

Automotive and rail transportation components

Electronic equipment structural parts

Casting

The alloy is melted and poured into molds to form ingots.

Heat Treatment

Solution heat treatment at approximately 540°C for 30 minutes, followed by rapid cooling and artificial aging at 100-180°C for several hours to achieve the T6 temper.

CNC Machining

CNC lathes, laser cutting, or sawing are used to produce discs with precise dimensions.

Surface Treatment

Anodizing: Enhances wear resistance and appearance

Electrophoretic Coating: Provides additional corrosion protection

Sandblasting: Improves surface uniformity and texture

| Alloy | Advantages | Disadvantages | Typical Applications |

| 6061 | High strength, good weldability, corrosion resistance | Slightly higher cost than 6063 | Automotive, aerospace, marine, structural parts |

| 6063 | Smooth surface, easy forming, low cost | Lower strength than 6061 | Home decoration, pipes, fittings |

| 5052 | Excellent weldability and corrosion resistance | Lower strength than 6061 | Food packaging, marine interiors, battery housings |

| 7075 | Extremely high strength (aerospace grade) | High cost, difficult machining | Aircraft wings, military equipment |

Copyright © 2026 By HAOMEI Aluminum CO., LTD. All Rights Reserved. Sitemap