No.14 Waihuan Road, CBD, Zhengzhou, China

No.14 Waihuan Road, CBD, Zhengzhou, China

+86-18703635966

+86-18703635966

No.14 Waihuan Road, CBD, Zhengzhou, China

No.14 Waihuan Road, CBD, Zhengzhou, China

+86-18703635966

+86-18703635966

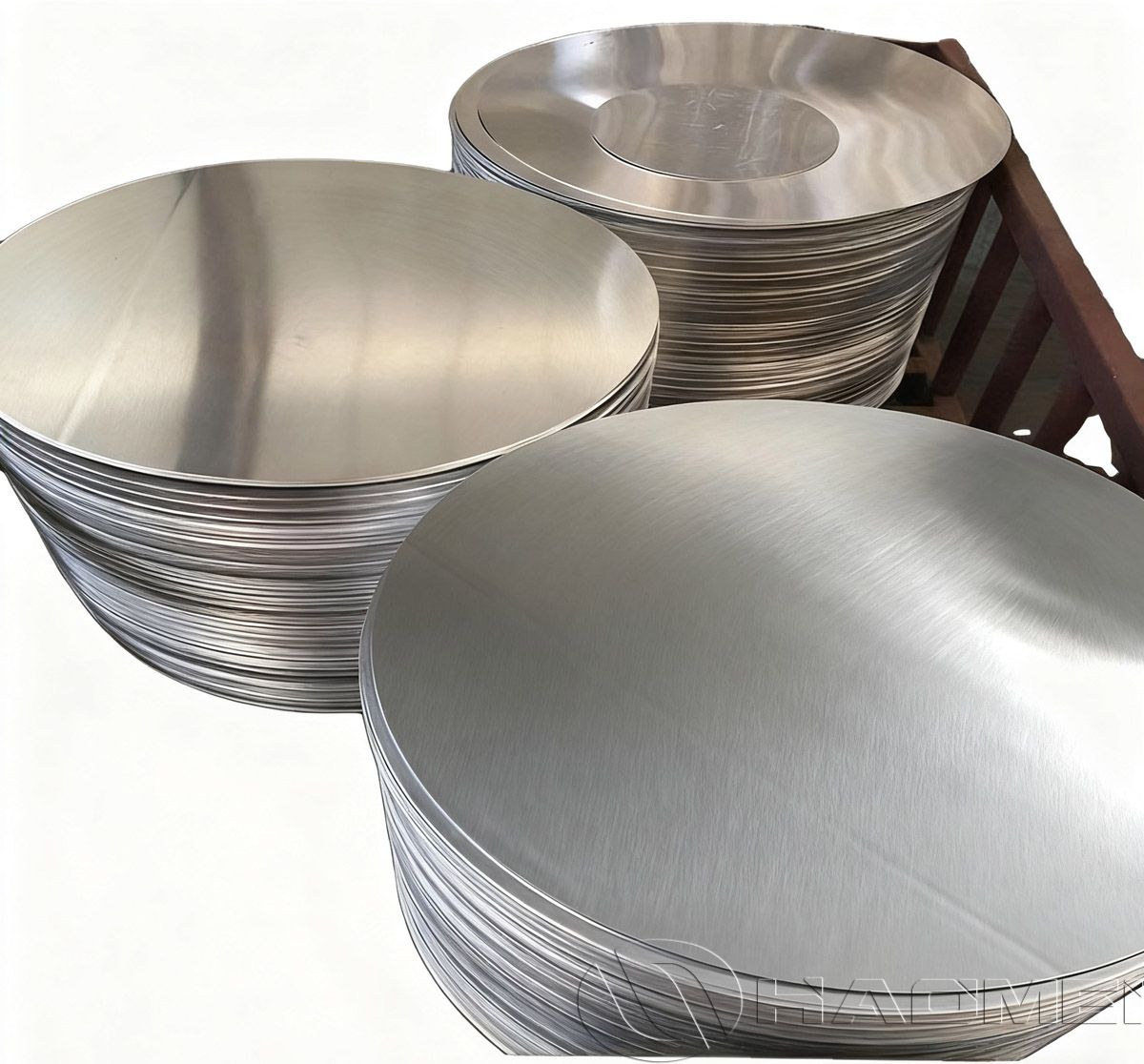

In modern industry and everyday products, 1000 series aluminum circle discs - including 1050, 1060, 1070, and 1100 - are widely used due to their lightweight, excellent formability, and broad applicability. Common applications include cookware, lighting, bottle caps, signage, decorative panels, and electrical housings.

Among aluminum alloys, the 1000 series stands out for its high purity and unique properties. In this article, we explore the differences among these four commonly used aluminum discs: 1050, 1060, 1070, and 1100.

| Element | 1050 (%) | 1060 (%) | 1070 (%) | 1100 (%) |

| Al | 99.50 min | 99.60 min | 99.70 min | 99.00 min |

| Fe | 0.40 max | 0.35 max | 0.25 max | 0.95 max |

| Si | 0.25 max | 0.25 max | 0.20 max | 0.95 max |

| Cu | 0.05 max | 0.05 max | 0.03 max | 0.05-0.20 |

| Mn | 0.05 max | 0.03 max | 0.03 max | 0.05 max |

| Zn | 0.05 max | 0.05 max | 0.03 max | 0.10 max |

| Other | 0.03 each | 0.03 each | 0.03 each | 0.15 total |

Key Points:

The main difference among 1050, 1060, and 1070 is the increasing aluminum purity. Higher purity improves electrical and thermal conductivity as well as ductility.

1100 aluminum has slightly lower purity but contains minor alloying elements, enhancing strength and corrosion resistance.

| Property | 1050 | 1060 | 1070 | 1100 |

| Tensile Strength (MPa) | 75-125 | 70-110 | 65-100 | 90-125 |

| Yield Strength (MPa) | 30-55 | 25-45 | 20-40 | 35-55 |

| Elongation (50mm %) | 25-35 | 25-35 | 25-30 | 20-30 |

| Hardness (Brinell) | 23-32 | 20-30 | 18-28 | 28-35 |

Key Points:

1100 aluminum has the highest strength due to copper content.

1070 aluminum is the softest and weakest but offers excellent ductility.

All alloys have excellent elongation, making them ideal for forming operations.

| Alloy | Melting Point (°C) | Density (g/cm³) | Electrical Conductivity (% IACS) | Thermal Conductivity (W/(m·K)) |

| 1050 | 650 | 2.7 | ≥59.0 | 227 |

| 1060 | 655 | 2.7 | ≥60.0 | 231 |

| 1070 | 658 | 2.7 | ≥61.0 | 237 |

| 1100 | 643 | 2.71 | ≥58.0 | 222 |

Key Points:

Electrical/thermal conductivity ranking: 1070 > 1060 > 1050 > 1100. Higher purity results in lower resistance and better conductivity. 1070 is optimal for heat and electrical conduction.

Density and melting point differences are minimal across these alloys.

Corrosion Resistance

| Alloy | Corrosion Resistance | Notes |

| 1050 | Excellent | Suitable for marine and chemical environments |

| 1060 | Excellent | Slightly better than 1050 due to lower impurities |

| 1070 | Outstanding | Highest purity minimizes electrochemical corrosion |

| 1100 | Very Good | Copper content slightly reduces resistance in acidic environments |

| Performance | 1050 | 1060 | 1070 | 1100 |

| Formability | Excellent | Excellent | Exceptional | Good |

| Weldability | Excellent | Excellent | Excellent | Excellent |

| Surface Treatment Compatibility | Good for anodizing | Good for anodizing | Good for anodizing | Strong compatibility with coating |

Key Points:

1100 aluminum hardens faster during cold working and requires annealing for deep drawing.

1070 aluminum is easiest to form due to minimal work hardening.

1050 Aluminum Discs

Lighting reflectors, signage, cookware bases, appliance housings

Features: Good formability, low cost, suitable for general stamping and spinning

1060 Aluminum Discs

CTP printing plates, lampshades, cookware, pressure cooker bottoms, food containers

Features: High ductility, suitable for anodizing and deep drawing

1070 Aluminum Discs

Electrical components, appliance panels, EMI shielding, transformer housings

Features: High purity, excellent conductivity and thermal transfer, ideal for electronics

1100 Aluminum Discs

Bottle caps, decorative panels, food packaging lids, architectural panels, traffic signage

Features: Good corrosion resistance, slightly higher strength, suitable for stamping, printing, and coating

Prioritize electrical/thermal conductivity and budget allows: choose 1070

Prioritize thermal conductivity and cost-effectiveness: choose 1060

Need finished product with higher strength or used in signage/cookware: choose 1100

Need general-purpose discs for deep drawing and stamping: choose 1050

Copyright © 2026 By HAOMEI Aluminum CO., LTD. All Rights Reserved. Sitemap