No.14 Waihuan Road, CBD, Zhengzhou, China

No.14 Waihuan Road, CBD, Zhengzhou, China

+86-18703635966

+86-18703635966

No.14 Waihuan Road, CBD, Zhengzhou, China

No.14 Waihuan Road, CBD, Zhengzhou, China

+86-18703635966

+86-18703635966

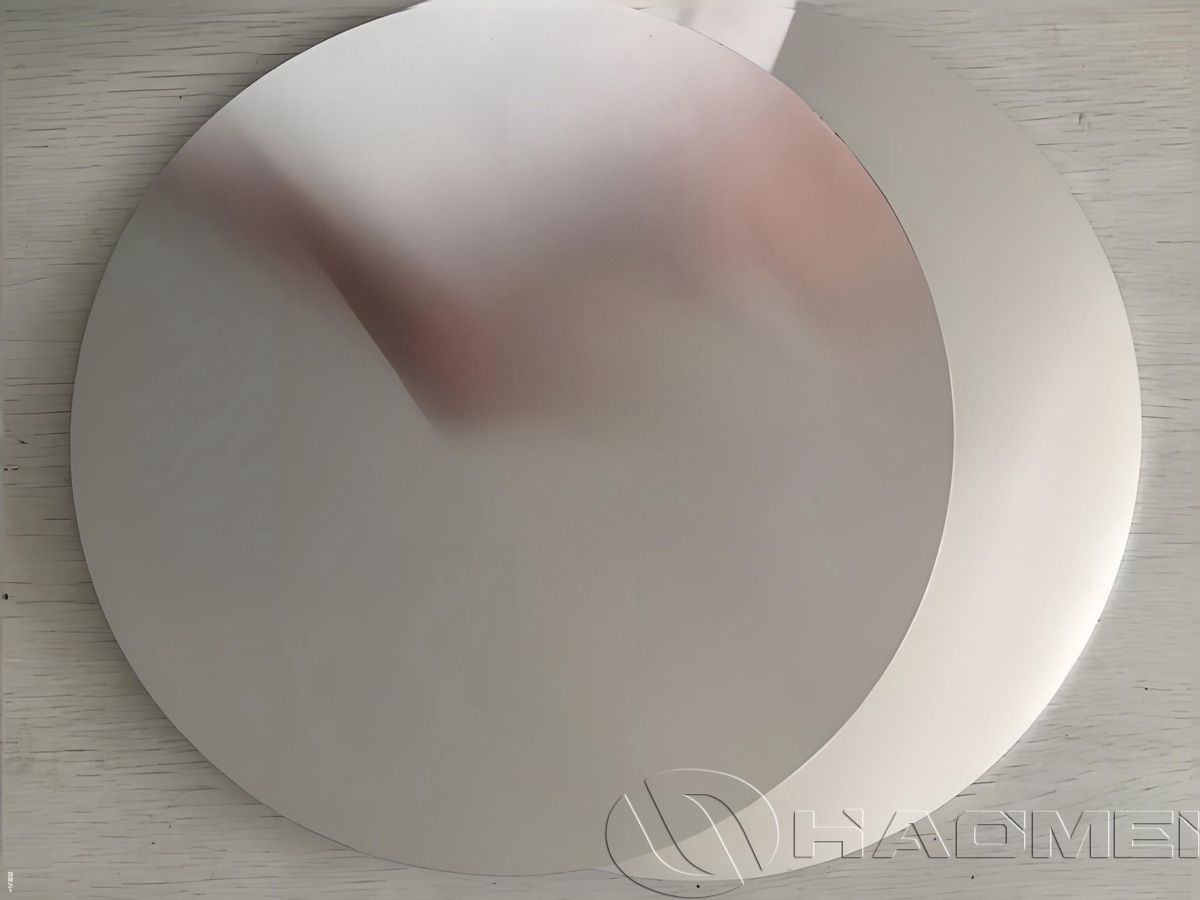

An aluminum circle, as the name suggests, is a round and flat aluminum material that serves as a key semi-finished product for manufacturing cookware such as pots, frying pans, pressure cookers, and kitchen utensils. Among various aluminum alloys, the 1070 aluminum circle, with its rolled surface and high purity (Al ≥ 99.7%), stands out for its excellent forming properties, making it ideal for kitchen and cookware applications.

Aluminum materials are generally produced through hot rolling or cold rolling processes. For cookware applications, the hot-rolled 1070 aluminum circle offers distinct advantages:

1. High Toughness and Ductility

During the hot rolling process, aluminum is rolled at high temperatures, which helps retain its excellent ductility and toughness. For cookware manufacturers, this means the material can withstand deep drawing and forming processes without cracking or tearing, improving production yield.

2. Excellent Surface Quality

The term "rolled surface" indicates that the circle has a smooth, uniform surface. This provides an ideal base for subsequent treatments such as non-stick coating, hard anodizing, or polishing, ensuring strong adhesion and a refined final appearance.

3. Dimensional Stability

The hot rolling process ensures consistent thickness and dimensional accuracy across the aluminum circle. This uniformity enhances heat conduction during cooking, allowing cookware to heat evenly and improve performance.

4. Compatibility with Various Secondary Processes

Hot-rolled aluminum circles are well-suited for stamping, deep drawing, welding, and coating, meeting the needs of different cookware types such as flat pans, rice cooker inner pots, and frying pans.

| Alloy | 1070 |

| Temper | H14 / H16 |

| Aluminum Purity | ≥ 99.7% |

| Thickness | 0.5mm - 6.0mm |

| Diameter | 100mm - 1200mm |

| Surface Finish | Mill finish, rolled surface, or matte |

| Production Process | Hot rolling / Cold rolling |

| Packaging | Standard seaworthy wooden pallet |

| Sample | Available |

| MOQ | 1-3 tons |

High Processing Efficiency: Uniform thickness and excellent ductility reduce material waste during forming.

Improved Cooking Performance: Even heat conduction ensures consistent temperature across the cookware body, preventing hot spots.

Lightweight Design: Reduces overall product weight, enhancing user comfort.

Corrosion Resistance & Durability: Naturally formed oxide film protects against rust and wear, extending service life.

Eco-Friendly & Safe: Pure aluminum contains no harmful substances and meets food-contact safety standards.

Non-stick & Frying Pans: Provide a uniform heat base for stable cooking temperatures.

Pressure Cookers: Excellent deep drawing performance makes it ideal for pot bodies and inner liners.

Skillets & Soup Pots: Good mechanical properties and formability allow for varied shapes and sizes.

Three-Layer Composite Cookware: 1070 aluminum circles are often used as the "core layer" in stainless-steel bottom pans. The high thermal conductivity of aluminum ensures fast, efficient heat transfer while maintaining the stainless steel’s aesthetic and durability.

Anodizing: Forms a hard, wear-resistant, corrosion-resistant oxide layer on the aluminum surface, which can be dyed in different colors for enhanced appearance.

Non-stick Coating: Provides an ideal base for coating adhesion, ensuring durable and uniform coverage.

The 1070 alloy belongs to the industrial pure aluminum series, meaning it consists almost entirely of aluminum with only trace elements (such as iron and silicon). Its simple chemical composition ensures high stability when in contact with food and prevents harmful substances from leaching out.

Usage Note:

Avoid prolonged cooking or storage of strongly acidic or alkaline foods (such as vinegar or lemon juice), even when coated, to protect both the surface finish and food safety.

Alloys such as 1050 and 1100 are also used in cookware manufacturing. However, 1070 has a slightly higher aluminum purity (99.7%), making it softer and more malleable. In contrast, 3003 aluminum alloy contains manganese for higher strength but slightly lower thermal conductivity. 5052 aluminum, known for superior strength and corrosion resistance, is typically used in marine or high-stress applications rather than cookware.

Aluminum cookware's biggest advantages are its fast heat transfer, lightweight structure, and competitive price. However, aluminum's natural softness and low scratch resistance require protective coatings or surface treatments for long-term durability.

Copyright © 2026 By HAOMEI Aluminum CO., LTD. All Rights Reserved. Sitemap