No.14 Waihuan Road, CBD, Zhengzhou, China

No.14 Waihuan Road, CBD, Zhengzhou, China

+86-18703635966

+86-18703635966

No.14 Waihuan Road, CBD, Zhengzhou, China

No.14 Waihuan Road, CBD, Zhengzhou, China

+86-18703635966

+86-18703635966

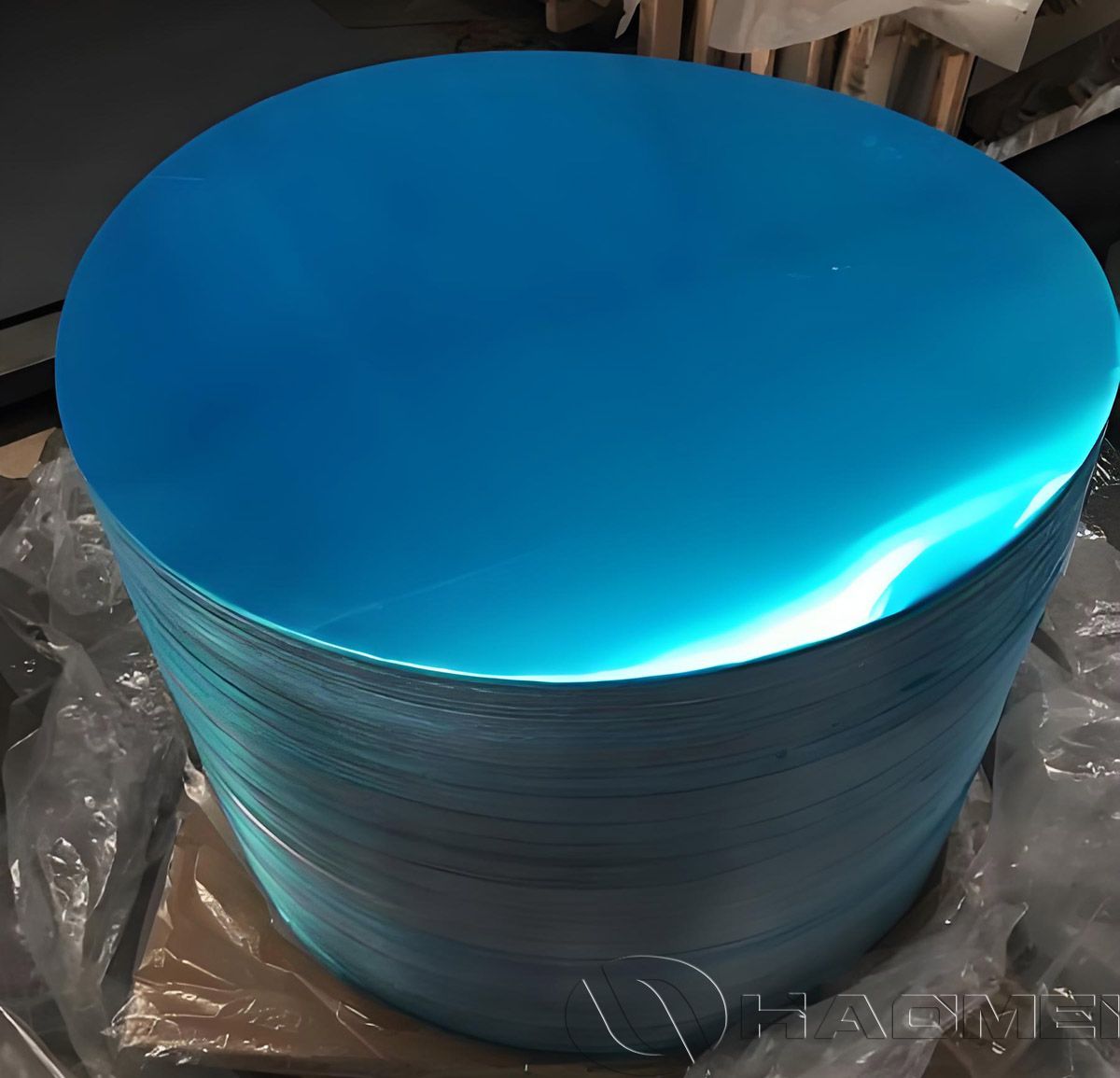

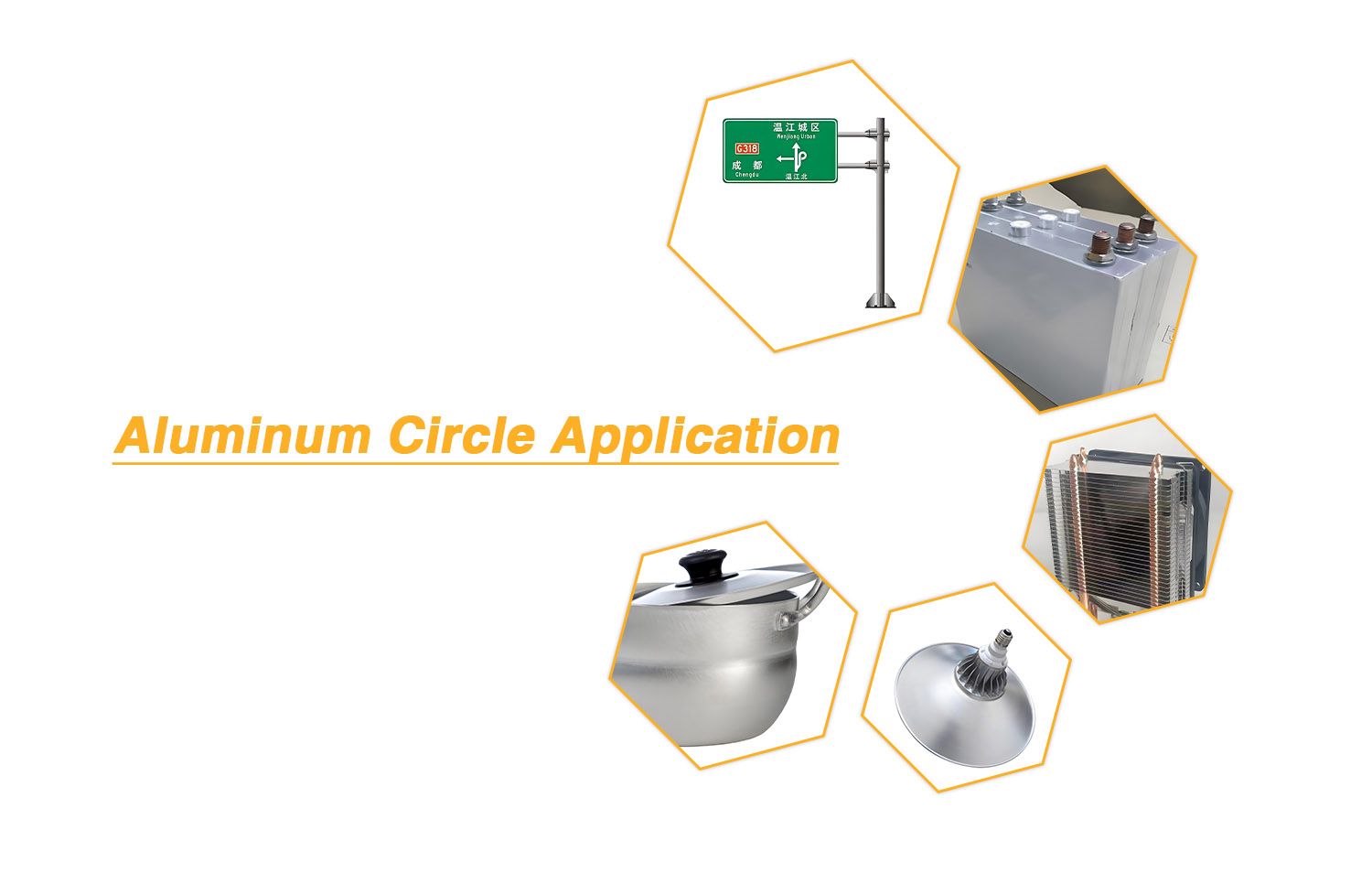

HAOMEI Aluminum, as a professional aluminum circle manufacturer, provides 1060 aluminum circles with thickness ranging from 0.5 to 6.0 mm and diameters from 80 to 1200 mm, supporting various annealing and temper states such as O, H12, H14, H16, H18, and more. These aluminum circles are widely used in industries including cookware, lighting, and signage.

1060 aluminum circles contain at least 99.6% aluminum, offering excellent ductility and tensile strength to meet conventional processing requirements such as stamping, drawing, and forming. Produced through a casting-rolling and cold rolling process, 1060 aluminum circles belong to one of the most common aluminum alloy series, known for their workability and corrosion resistance.

1060 aluminum circles can be supplied in multiple temper states, including O, H12, H14, H16, H18, H22, and H24, to meet different processing needs.

O State (Fully Annealed):

The O state is fully annealed, providing the highest ductility and lowest strength. It is ideal for deep drawing or severe forming processes.

H12 (1/4 Hard):

Lightly cold-worked, H12 increases material strength compared to O state while maintaining good formability. Hardness is typically HB 30-35, balancing strength and flexibility, suitable for applications requiring moderate support without compromising stamping processes.

H14 (1/2 Hard):

Medium-hard state achieved through further cold rolling. H14 1060 aluminum circles combine mechanical strength with good workability, making them ideal for traffic signs, appliance housings, and electrical panels.

H16 (3/4 Hard):

Offers higher strength while retaining sufficient formability for general fabrication.

H18 (Full Hard):

Fully cold-worked, H18 provides maximum strength and minimum ductility, suitable for applications with high-strength requirements and minimal deformation.

H22/H24 (Partially Annealed):

These partially hardened states balance strength and ductility, maintaining sufficient formability while improving material strength.

| Temper State | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) | Vickers Hardness (HV) | Brinell Hardness (HB) |

| O | 60-90 | ≤30 | 25-35 | 20-25 | 20-25 |

| H12 | 90-110 | 35-45 | 20-25 | 30-35 | 30-35 |

| H14 | 110-130 | 50-60 | 10-20 | 35-40 | 35-45 |

| H16 | 120-140 | 60-70 | 8-15 | 40-45 | 40-50 |

| H18 | ≥140 | ≥120 | 5-10 | 50-55 | 50-55 |

| H22 | 90–110 | 35-45 | 22-28 | 28-33 | 28-33 |

| H24 | 105–125 | 45-55 | 18-25 | 32-38 | 32-38 |

Excellent Plasticity: Easy to perform deep drawing, stretching, and bending operations.

Superior Electrical and Thermal Conductivity: Among the highest in aluminum alloys, second only to 1050.

Good Corrosion Resistance: Stable in atmospheric, water, and some chemical environments.

Low Strength: As a non-heat-treatable alloy, strength is mainly obtained through cold working (work hardening).

Deep Drawing Products: Ideal for aluminum pots, pans, and lamp reflectors, requiring O state to withstand multiple deep drawing processes without cracking.

Electronic Components: High conductivity applications may use O, H12, or H14 states, balancing electrical performance and mechanical strength.

Packaging Materials: Used for pharmaceutical packaging, food containers, and other applications requiring non-toxic, easily formable material.

Copyright © 2026 By HAOMEI Aluminum CO., LTD. All Rights Reserved. Sitemap