No.14 Waihuan Road, CBD, Zhengzhou, China

No.14 Waihuan Road, CBD, Zhengzhou, China

+86-18703635966

+86-18703635966

No.14 Waihuan Road, CBD, Zhengzhou, China

No.14 Waihuan Road, CBD, Zhengzhou, China

+86-18703635966

+86-18703635966

Aluminum circle discs for lamps are primarily used in the manufacture of lampshades and reflectors. They also offer excellent heat dissipation, corrosion resistance, and environmental friendliness, effectively extending the lifespan of lamps. HAOMEI Aluminum also produces high-quality anodized and painted aluminum discs for various lampshades. These discs undergo various surface treatments to achieve the desired appearance and color, enhancing product durability.

Lampshade aluminum blanks are typically produced from 1000, 3000, 5000, or 8000 series aluminum alloys through precision rolling, stamping, and cutting processes. The surface treatment methods are diverse, including anodizing, spraying, and brushing, to meet both decorative and functional requirements. Sizes such as thickness and diameter can be customized to ensure perfect product adaptability.

1000 Series Aluminum Circles

Represented by 1050, 1060, and 1100, these pure aluminum discs have an aluminum content of over 99% and a density of only 2.71 g/cm³ (about one-third that of steel). This lightweight property significantly reduces the overall weight of lampshades, especially for large chandeliers and outdoor landscape lamps requiring suspension. The natural oxide film formed on the surface effectively resists moisture, allowing a service life of more than 15 years in high-humidity environments such as kitchens and bathrooms-far longer than traditional plastic or glass materials.

3000 Series Aluminum Circles

3003 aluminum discs are alloyed with manganese, maintaining the corrosion resistance of 1000 series aluminum while improving tensile strength to 120–160 MPa with elongation up to 20%. This makes them ideal for lampshades requiring complex designs. Whether for indoor or outdoor lighting (such as garden lamps and wall lamps), 3003 aluminum discs combine strength with excellent formability.

5000 Series Aluminum Circles

5052/5754 aluminum discs are magnesium alloys with a thermal conductivity of up to 180 W/(m·K), about 1.5 times higher than standard aluminum alloys. In LED lampshades, this rapid heat dissipation effectively lowers light source temperature, extending LED lifespan by more than 30%. The hardness (HB60) also ensures better resistance to impact during transportation, reducing deformation rates.

The diameter (D) and thickness (T) are key parameters that influence lampshade design, manufacturing cost, and optical performance.

The lampshade diameter is determined by the disc diameter.

The lampshade depth depends on the thickness-thicker discs are required for deeper lampshades to withstand thinning during spinning.

Spinning / Stamping: easy to deep draw and form various lampshade shapes.

Anodizing: improves surface hardness and aesthetics, widely used in high-end lighting.

Spraying / Sandblasting: enhances decorative appearance with multiple surface effects.

Mirror Polishing: boosts reflectivity, ideal for energy-saving and LED lamps.

| Alloys | 1050, 1060, 1070, 1100, 3003, 5052, 5754, etc. |

| Temper | O - H112 |

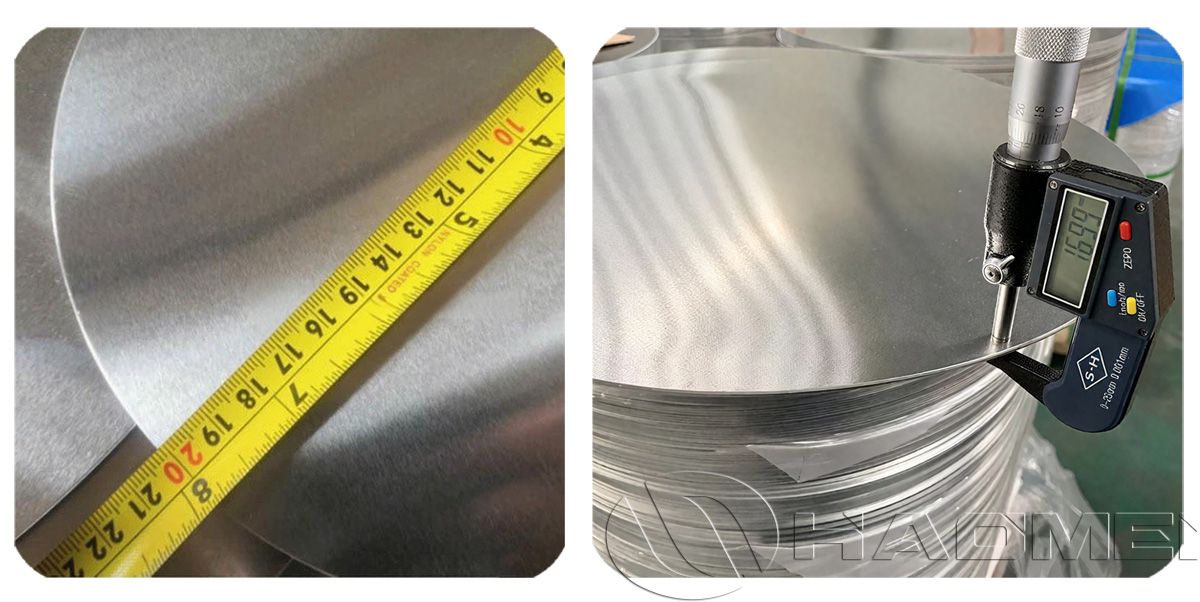

| Diameter | 80mm - 1600mm |

| Thickness | 0.5mm - 6.0mm |

| Processing services | decoiling, cutting |

| Color | silver, customizable |

| Shape | round |

| Production process | CC/DC |

| Surface treatment | anodizing, coating, brushing, etc. |

| Applications | lampshades, cookware, traffic signs, etc. |

| Packaging | standard seaworthy packaging |

| Samples | 1-3 pcs |

| MOQ | 1-3 tons |

Tolerances for Lampshade Aluminum Discs

| Hollow and regular aluminum circle | |||

| Thickness (mm) | Diameter range (D) (mm) | ||

| 0.5-6.0 | D ≤ 455 | 455 < D ≤ 1000 | 1000 < D ≤ 1200 |

| ±0.01 | ±0.079 | ±0.099 | ±0.015 |

| Maximum sizes may vary depending on specific requirements. | |||

Lightweight: aluminum's density is only one-third of steel, making lampshades lighter and easier to install.

High reflectivity: anodized or mirror-polished aluminum discs reach reflectivity above 80%, enhancing lighting efficiency.

Corrosion resistance: natural oxide film protects performance in humid or dusty environments.

Excellent formability: aluminum discs can be easily spun, stamped, or deep drawn into various lampshade designs.

In addition to different alloys and sizes, lampshade aluminum circles can also be distinguished according to performance and processing effects: ordinary aluminum circles, anodized aluminum circles, color-coated aluminum circles, brushed aluminum circles, etc.

Accurate size control with minimal tolerance.

High surface quality: free of scratches, oil stains, oxidation spots, or dark marks.

Smooth edges: burr-free and neatly finished.

Excellent grain size and elongation: ensures superior deep-drawing and stamping performance while minimizing risks of tearing, wrinkling, or earing.

Safe packaging: waterproof, moisture-proof, and impact-resistant.

Short delivery time: large inventory available for fast shipment.

Copyright © 2026 By HAOMEI Aluminum CO., LTD. All Rights Reserved. Sitemap