No.14 Waihuan Road, CBD, Zhengzhou, China

No.14 Waihuan Road, CBD, Zhengzhou, China

+86-18703635966

+86-18703635966

No.14 Waihuan Road, CBD, Zhengzhou, China

No.14 Waihuan Road, CBD, Zhengzhou, China

+86-18703635966

+86-18703635966

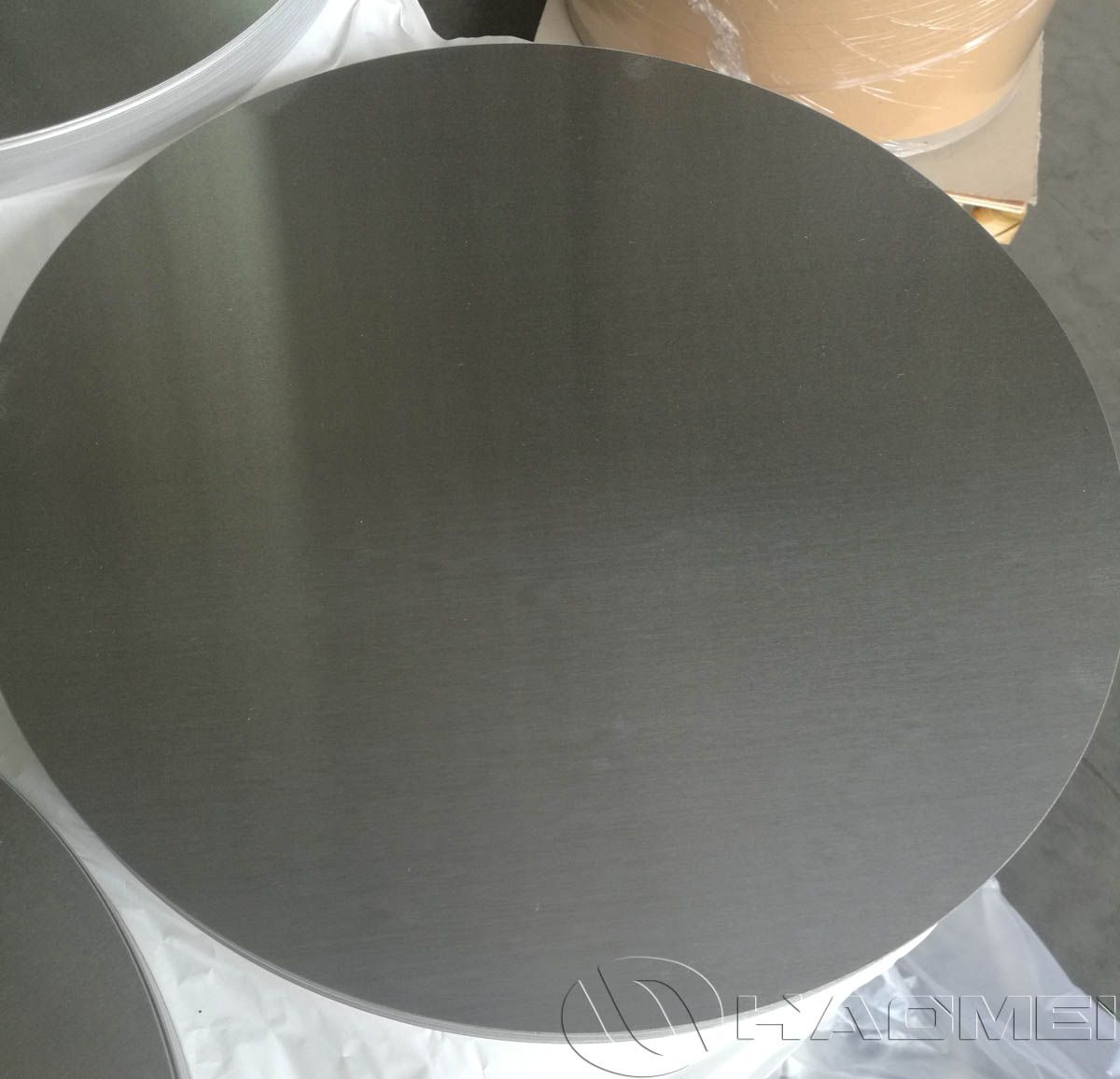

5052 aluminum alloy belongs to the Al-Mg series, containing 2.2%-2.8% magnesium. It is one of the most widely used anti-corrosion aluminum alloys and is recognized as a marine-grade aluminum alloy, suitable for long-term use in salt-spray, high-humidity, and high-pressure marine environments.

Thanks to its light weight, corrosion resistance, and medium strength, 5052 aluminum circles are increasingly used as an important alternative to traditional steel, ideal for manufacturing various marine components.

5052 aluminum discs are commonly supplied in O, H32, and H34 tempers, each fitting different fabrication requirements in the shipbuilding industry.

| Temper | Characteristics | Marine Applications |

| O | Very soft, excellent ductility, easy to form | Deep drawing, stamping, complex components such as cabin end covers, pipe fittings |

| H32 | Medium strength, good ductility | Moderate-strength parts requiring dimensional stability, such as cabin plates and lightweight structures |

| H34 | Higher strength, lower ductility | Components requiring better load-bearing capability, such as structural accessories and pressure vessel parts |

HAOMEI Aluminum, as a professional manufacturer of aluminum discs, provides internationally recognized certifications for its 5052 marine-grade aluminum discs, such as DNV, ABS, BV, and CCS. This is an important guarantee that the materials meet the quality requirements for marine applications.

| Alloy | 5052 |

| Temper | O, H32, H34 |

| Thickness | 0.5-6.0 mm |

| Diameter | 100-1200 mm |

| Tolerance | Customizable |

| Surface Options | Mill finish, matte, anodized, coated (customizable) |

| Key Features | Corrosion-resistant, seawater-resistant, weldable, suitable for deep drawing |

| MOQ | 1-3 tons |

1. Outstanding Corrosion Resistance

With 2.2-2.8% magnesium content, 5052 aluminum forms a dense, stable magnesium oxide film capable of resisting oxidation in humid and salt-rich environments-far superior to alloys in the 1xxx and 3xxx series.

2. Moderate Strength for Marine Structures

The tensile and yield strength of 5052 (especially H32/H34) makes it capable of withstanding operational loads in marine components.

3. Excellent Formability

5052 aluminum circles are ideal for deep drawing, spinning, stretching, and other cold-forming processes, meeting the needs of complex marine parts.

4. Superior Weldability

5052 offers excellent weldability with all common welding methods (e.g., TIG, MIG), essential for large marine components.

5. More Cost-effective Than High-end Marine Alloys

Compared with 5083 and 5086 marine-grade alloys, 5052 offers lower cost and easier processing while maintaining good corrosion resistance.

1. Hull Structures & Exterior Components

Used for small-to-medium boat hull panels, deck cabins, and side protection plates. Its lightweight property improves speed and fuel efficiency.

2. Internal Systems & Equipment

Applicable to fuel tanks, water tanks, ventilation ducts, and cable trays, benefiting from its corrosion resistance and safety in humid environments.

3. Marine Hardware & Decorative Parts

Used in marine door frames, dashboard brackets, ladder anti-slip plates, and decorative trims. Anodizing enhances appearance and weather resistance.

4. Special Marine Equipment

Preferred for marine HVAC sheet-metal parts that operate under long-term high-humidity and high-salt conditions.

5052 aluminum vs. 5083: 5052 has moderate strength but superior formability, making it easier to stamp and bend. It is ideal for manufacturing complex sheet metal parts and non-load-bearing structures, and is generally more cost-effective.

vs. 6061 aluminum: 6061 can achieve higher strength through heat treatment, but 5052 is generally considered to have better corrosion resistance in marine environments. For components that are in direct, long-term contact with seawater, the corrosion resistance of 5052 is a primary consideration.

Copyright © 2026 By HAOMEI Aluminum CO., LTD. All Rights Reserved. Sitemap