No.14 Waihuan Road, CBD, Zhengzhou, China

No.14 Waihuan Road, CBD, Zhengzhou, China

+86-18703635966

+86-18703635966

No.14 Waihuan Road, CBD, Zhengzhou, China

No.14 Waihuan Road, CBD, Zhengzhou, China

+86-18703635966

+86-18703635966

In high-volume metal forming, the performance of an aluminum disc is determined long before it reaches the press. Grain structure control, thickness stability, surface condition, and edge quality all influence forming yield and finished appearance. As a manufacturer of aluminum circles and discs, we produce cold rolled 3003 aluminum discs to meet demanding requirements for deep drawing, spinning, stamping, and subsequent finishing processes such as anodizing, coating, or polishing.

Alloy 3003 (Al-Mn) remains a preferred choice when customers need a practical balance of formability, corrosion resistance, and cost efficiency. Compared with general-purpose commercial aluminum, 3003 provides improved strength with excellent workability, making it widely specified for cookware, lighting reflectors, signage blanks, and general forming components.

This article explains how we manufacture cold rolled 3003 aluminum discs, what technical parameters we control, and how customers can specify dimensions and performance for stable, repeatable production.

3003 aluminum is an Al-Mn alloy where manganese improves strength and corrosion resistance while maintaining good ductility. For disc applications, we manage rolling reduction and heat treatment to deliver consistent forming behavior batch to batch.

Typical performance expectations for 3003 aluminum disc material include:

Good deep drawability and spinning performance

Stable mechanical properties across the coil and across lots

Good corrosion resistance for wet-use products

Compatibility with common surface treatments (anodizing, coating, lacquering)

For many end uses, cold rolling provides advantages that support dimensional and surface consistency:

Tighter thickness tolerance and improved flatness control

More uniform surface appearance suitable for decorative finishing

Better gauge repeatability for progressive stamping or multi-step drawing

Customers typically select cold rolled 3003 aluminum discs when they need predictable forming behavior and surface quality that can be carried directly into finishing.

The table below reflects our normal production capability for cold rolled 3003 aluminum circle and disc blanks. Final supply is confirmed by agreed specification and feasibility review.

| Item | Typical Specification Range | Notes |

|---|---|---|

| Alloy | 3003 | Other 3xxx alloys available on request |

| Temper | O, H12, H14, H16, H18 | O for deep drawing; H14 common for stamping |

| Thickness | 0.30 mm to 6.00 mm | Based on coil availability and disc diameter |

| Diameter | 80 mm to 1200 mm | Larger sizes by evaluation |

| Thickness tolerance | As per agreed standard | Tighter tolerances available for critical parts |

| Diameter tolerance | As per agreed standard | Defined by tooling and inspection plan |

| Flatness | Controlled per application | Important for stamping and reflector forming |

| Surface finish | Mill finish, bright finish (optional) | Depends on rolling and finishing route |

| Edge | Sheared and deburred | Burr control for automated handling |

| Protective packing | Interleaving paper, PE film (optional) | Export packing, palletized |

| Standards support | ASTM, EN, JIS (by agreement) | Final per PO and technical confirmation |

We manufacture discs in a controlled sequence designed to protect formability and appearance.

We start from qualified 3003 alloy coils with defined chemistry and cleanliness requirements. Each coil is checked for:

Alloy identification and heat traceability

Surface condition and contamination control

Gauge and camber suitability for blanking

Cold rolling reduction and thermal cycles directly influence grain structure and earing behavior during deep drawing. For deep-draw grades, we use annealing practices to achieve:

Stable elongation and low variability

Controlled grain size and texture

Consistent coil-to-coil forming response

Discs are produced by precision punching/blanking. Tooling condition is managed to ensure:

Tight diameter control

Minimal burr height

Clean, uniform edge quality to reduce cracks during spinning and drawing

Depending on customer requirements, we pack discs with interleaving paper, anti-scratch film, and moisture protection. Packing is designed for export logistics and to maintain surface quality for anodizing or decorative use.

Our quality system focuses on controlling key-to-quality characteristics that affect downstream forming and appearance.

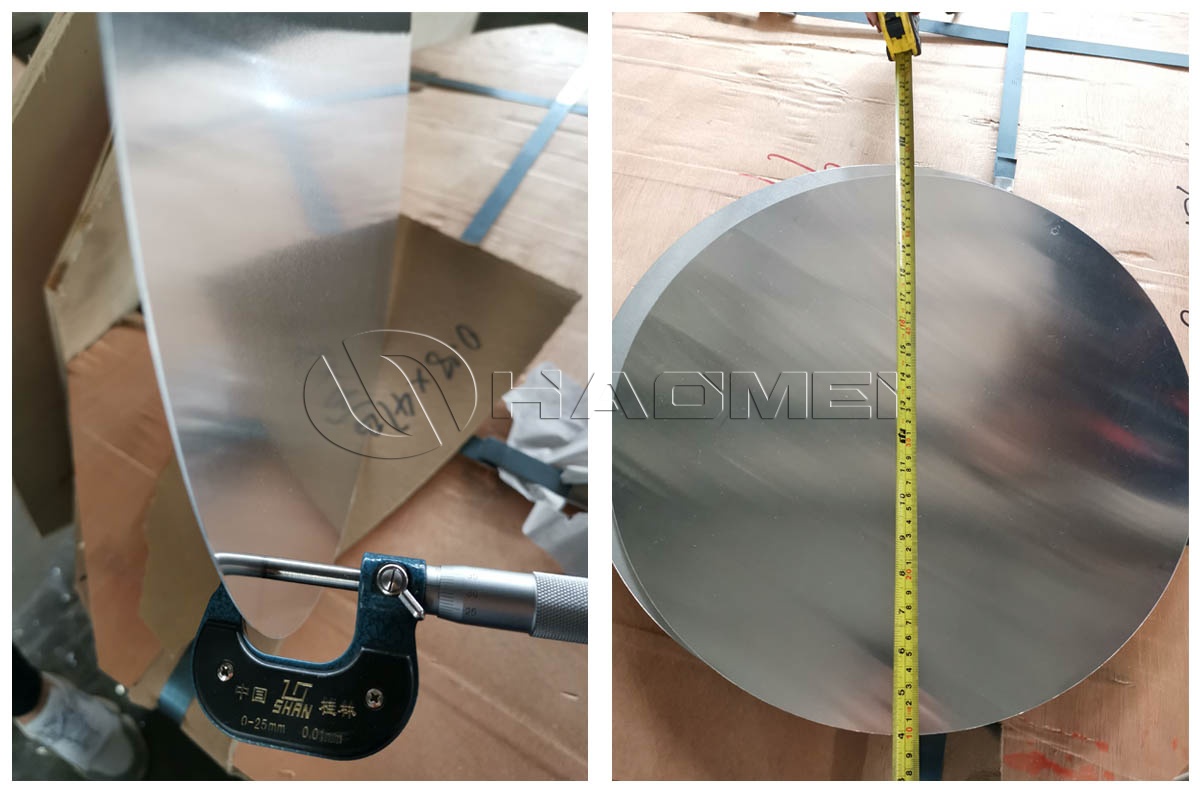

We verify thickness and dimensional stability through routine in-process checks and final inspection based on the sampling plan.

Key inspection items typically include:

Thickness mapping and gauge stability

Diameter measurement and roundness

Flatness checks for stamping suitability

Burr height and edge condition

Visual inspection for scratches, roll marks, and stains

For tempers such as O and H14, we control mechanical properties by monitoring rolling reductions and heat treatment parameters. Where required, we provide test data aligned with the agreed standard and acceptance criteria.

We support supply aligned to commonly used standards (ASTM, EN, JIS) by agreement. Documentation can include:

Mill test certificate (MTC) or inspection certificate format per request

Heat number traceability

Packing list and identification labeling

Many customers use 3003 discs in automated lines where repeatability is critical. We can customize:

Temper selection: O for deep drawing and spinning, H14 for stamping rigidity, other tempers on request

Surface requirements: controlled mill finish, bright finish route (when applicable), film protection

Dimensional tolerances: tighter diameter and thickness tolerances for matched tooling and multi-cavity dies

Edge condition: burr limitation and deburring requirements tailored to automated feeding

Packaging: interleaving, film, carton or crate solutions, pallet structure for container loading

For customers sourcing a standardized specification, our dedicated product pages for 3003 Aluminum Circle and 3000 Series Aluminum circle provide a clear starting point for technical alignment.

Cold rolled 3003 aluminum discs are widely used where forming quality and corrosion resistance are primary requirements.

Cookware and Kitchenware

Pots, pans, lids, pressure cooker components

Deep drawn and spun cookware bodies

Good heat transfer and corrosion resistance for daily use

Lighting and Reflector Components

Reflector blanks and spun shades

Components requiring stable surface quality for reflective finishes

Signage, Nameplates, and Decorative Parts

Stamped or formed discs used as base material

Suitable for coating, printing, or anodizing depending on finishing route

General Deep Drawing and Spinning Components

Industrial covers, housings, formed shells

Parts requiring stable forming behavior across multiple drawing steps

| Property | 3003 (Al–Mn) | 1050/1060 (Pure Al) | 5052 (Al-Mg) | 3004 (Al-Mn-Mg) |

| Main composition | Contains Mn 1.0-1.5% | Al ≥ 99.5% | Contains Mg 2.2-2.8% | Contains Mn and Mg |

| Strength (UTS) | Medium (~110-190 MPa) | Lower (~60-110 MPa) | Higher (~210-260 MPa) | Higher than 3003 |

| Formability | Excellent; suitable for deep drawing and spinning | Excellent; soft, good workability, but higher springback | Good | Good |

| Corrosion resistance | Excellent, especially atmospheric corrosion resistance | Excellent | Outstanding; excellent seawater corrosion resistance | Excellent |

| Main applications | Main applications | - | High-strength parts, fuel tanks | Beverage can bodies, color-coated aluminum base material |

| Cost | Moderate | Low | Higher | Higher |

As a manufacturing facility focused on aluminum circles and discs, we supply cold rolled 3003 aluminum discs with controlled thickness, diameter stability, and edge quality suitable for deep drawing, spinning, stamping, and finishing operations. Our production and inspection processes are built around forming consistency, traceability, and export-ready packing.

For long-term programs, we support specification confirmation, sampling, and continuous quality feedback to maintain stable mass production. If you share your disc size range, temper, forming method, and surface expectations, our technical team will propose a manufacturing route and quality plan aligned with your application and supply schedule.

Copyright © 2026 By HAOMEI Aluminum CO., LTD. All Rights Reserved. Sitemap